Converter smelting process with low lime consumption

A converter smelting and lime technology, which is applied in the field of iron and steel metallurgy converter steelmaking, can solve the problems of increased explosion venting times, increased iron and steel material consumption, and increased furnace repair times, and achieves significant social and economic benefits, reduced iron and steel material consumption, Guarantee the effect of direct production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Specific steps are as follows:

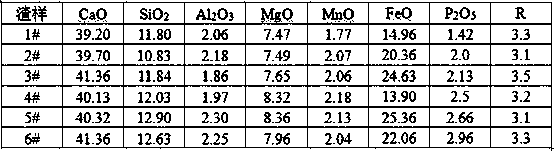

[0045] (1) According to P in the final slag of the converter 2 o 5 (see 1# slag sample in Table 1), determine that the amount of slag left in the furnace is 60kg / t steel, and tap the steel after pouring out the corresponding slag;

[0046] (2) Since the percentage content of FeO in the slag of this furnace is 14.96%, there is no need to add deoxidizers such as coke ding after tapping. Lightly burned dolomite for slag splashing to protect the furnace. During the slag splashing process, ensure that the final slag is completely splashed on the inner wall of the furnace lining and that all the final slag is completely solidified;

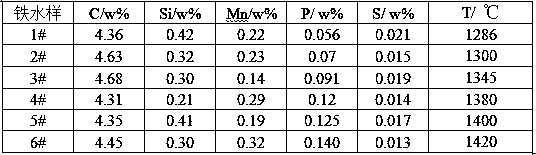

[0047] (3) The furnace corresponds to a molten iron temperature of 1286°C (1# molten iron sample in Table 2), adding 12t of steel scrap, the total load of the converter is 150t, the ratio of steel scrap is 8%, and tilting the converter 75° before and after adding scrap , so that the scrap steel is evenly spread...

example 2

[0058] Specific steps are as follows:

[0059] (1) According to P in the final slag of the converter 2 o 5 Composition (see 2# slag sample in Table 1), determine the amount of slag left in the furnace to be 51kg / t steel, and tap the steel after pouring out the corresponding slag;

[0060] (2) Since the percentage content of FeO in the slag of this furnace is 20.36%, 50kg of coke is added after tapping, and 600kg of light-burned dolomite is added according to the control requirements of the amount of slag remaining and the MgO content of 5.5w% in the slag during the dephosphorization period Carry out slag splashing to protect the furnace, ensure that the final slag is completely splashed on the inner wall of the furnace lining during the slag splashing process, and ensure that all the final slag is completely solidified;

[0061] (3) The furnace corresponds to a molten iron temperature of 1300°C (2# molten iron sample in Table 2), adding 15t of steel scrap, the total load of ...

example 3

[0072] Specific steps are as follows:

[0073] (1) According to the final slag composition of the converter (see 3# slag sample in Table 1), the amount of slag remaining in the furnace is determined to be 50kg / t steel, and the steel is tapped after pouring out the corresponding slag.

[0074] (2) Since the content of FeO in the slag is 24.63%, which is relatively high, in order to prevent the furnace lining from eroding and splashing with iron, according to the requirement of adding 1.5kg of carbon powder / t of slag for every 1% decrease in FeO content, add 88kg of coke.

[0075] (3) According to the amount of slag remaining and the control requirements of 5.5w% MgO content in slag during the dephosphorization period, directly add 600kg of light-burned dolomite for slag splashing to protect the furnace. During the slag splashing process, ensure that the final slag is completely splashed on the inner wall of the furnace lining and ensure All final slag is completely solidified; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com