Preparation method of sulfur-doped bifunctional oxygen catalyst based on ZIF-67 and conductive graphene

A technology of ZIF-67 and conductive graphite, which is applied in the field of preparation of bifunctional oxygen catalysts, achieves the effects of large-scale production, good conductivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] (1) Preparation of precursor ZIF-67: Weigh cobalt nitrate hexahydrate and dimethylimidazole with a mass ratio of 1:1.5~2, respectively dissolve them in the same volume of anhydrous methanol, and mix the above solutions Uniform and sonicate for 15 minutes, then let the sonicated mixed solution stand still, settle for 5~6 hours, collect the precipitate, wash the precipitate with anhydrous methanol several times, and then disperse the precipitate in absolute ethanol for later use, that is, ZIF- 67;

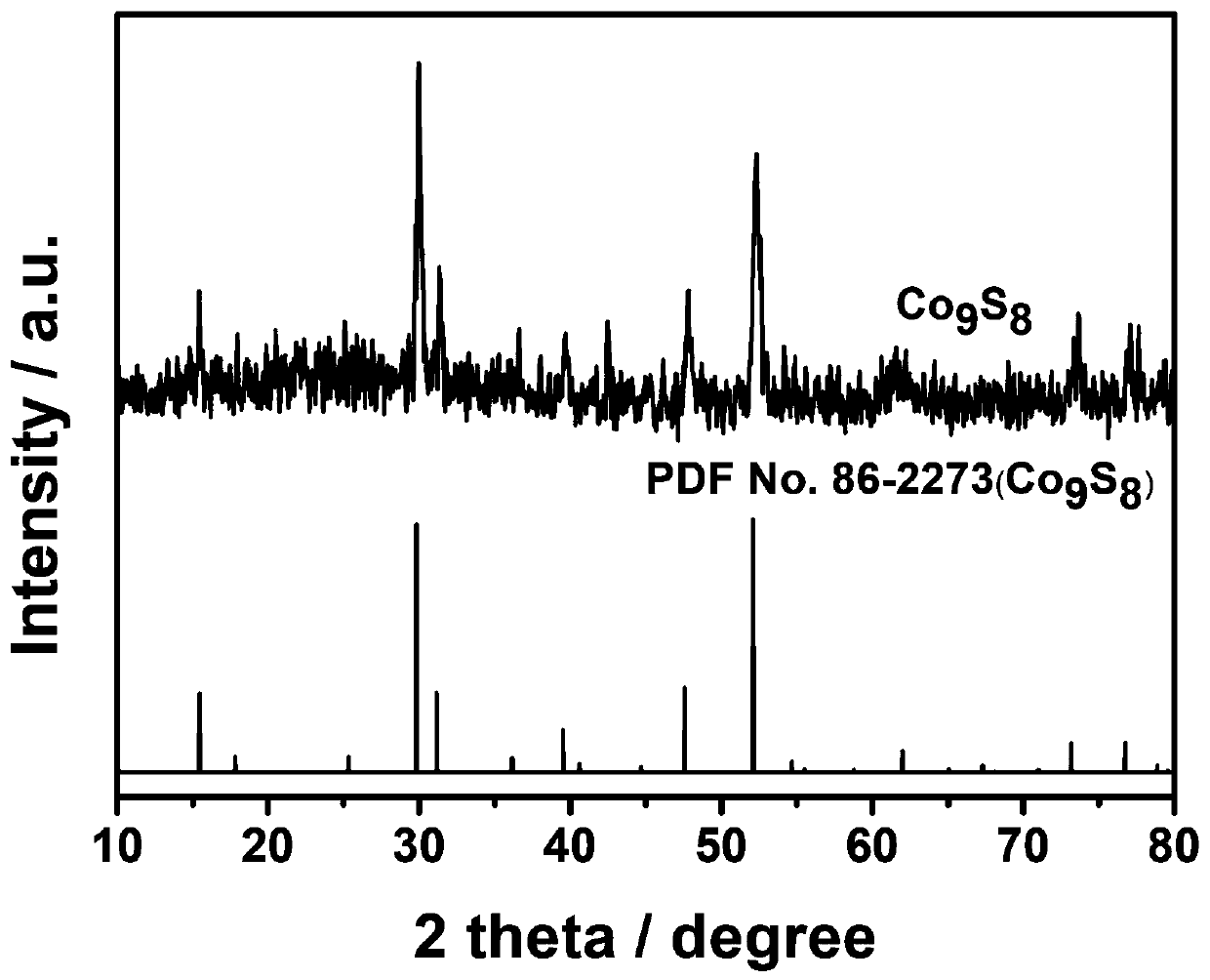

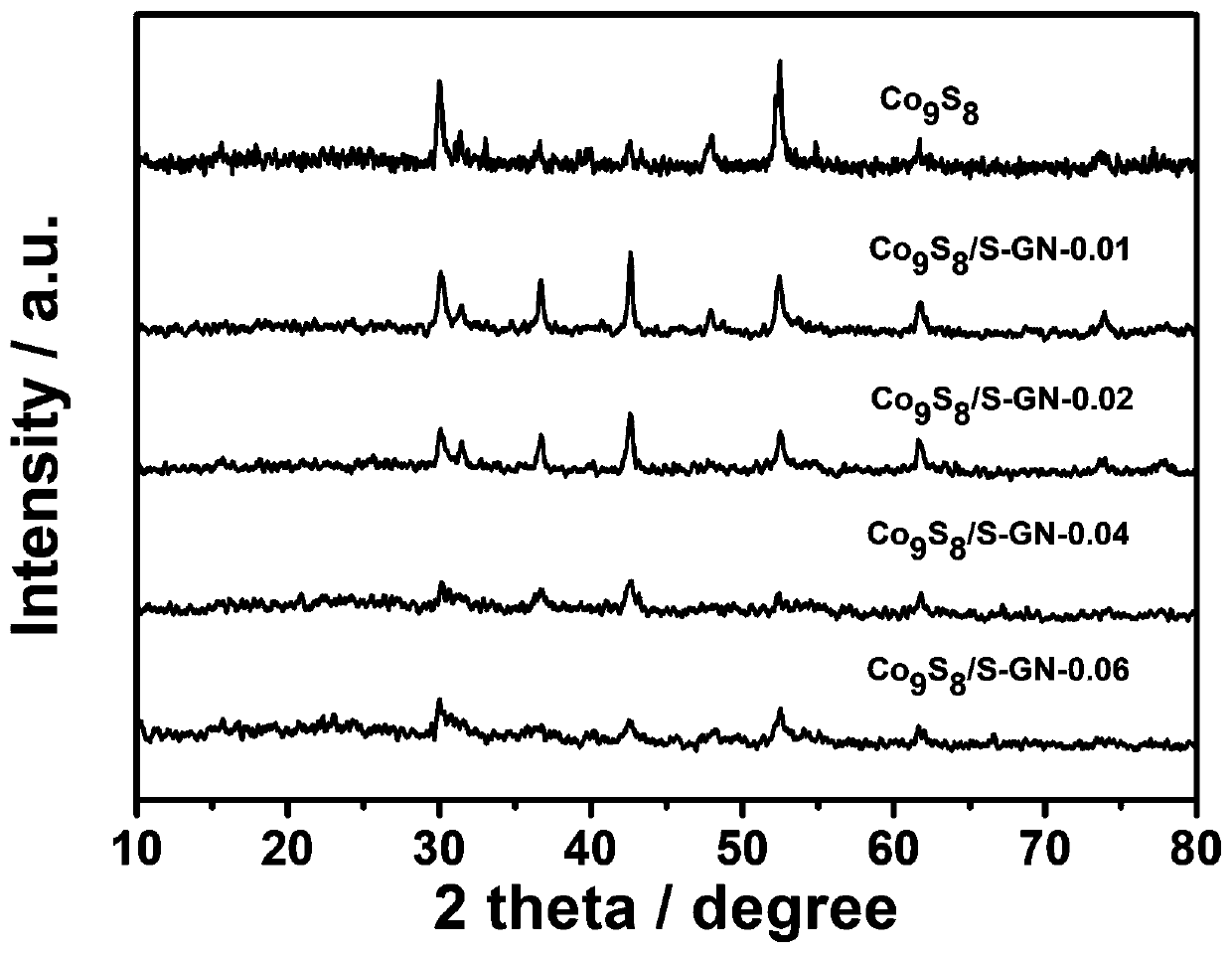

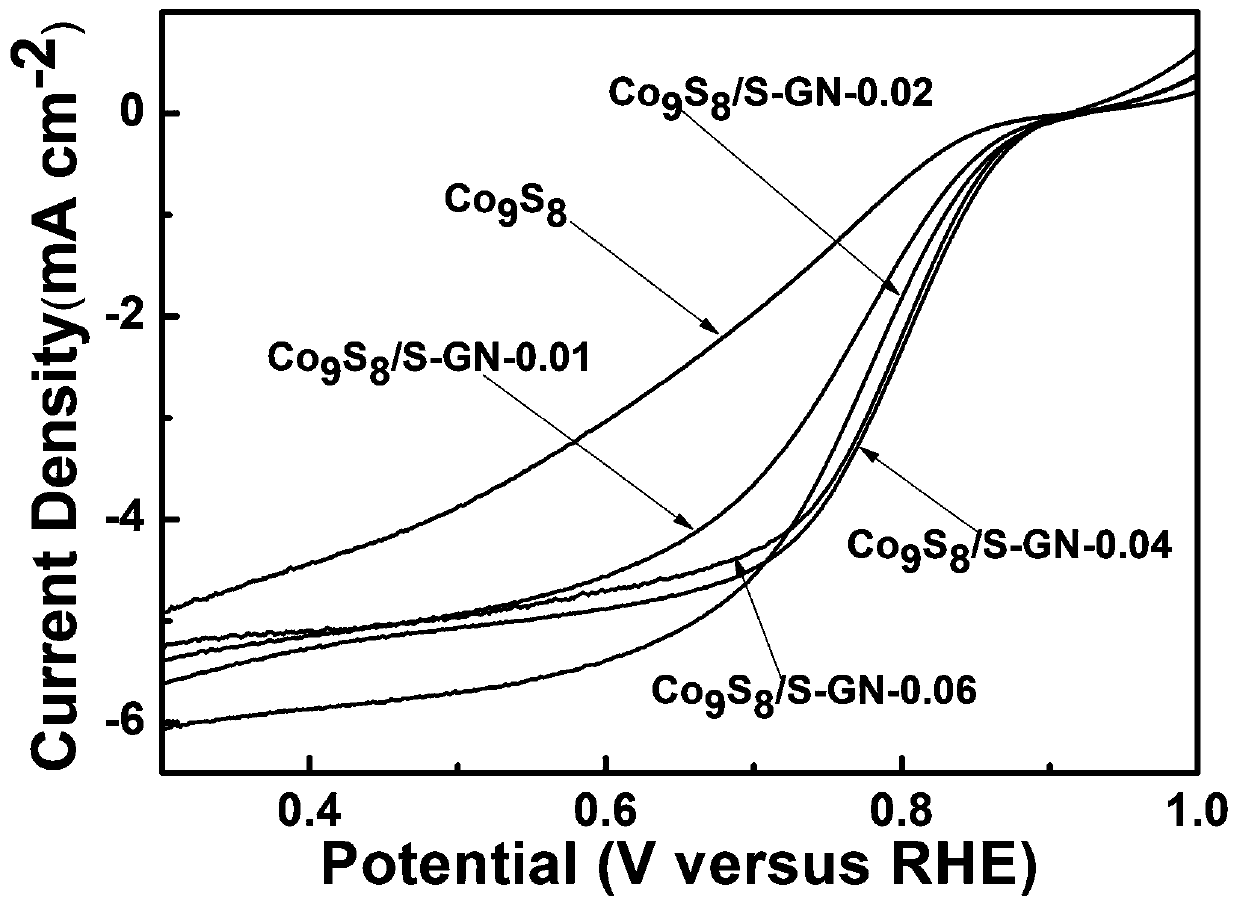

[0026] (2) Co. 9 S 8 Preparation of / S-GN bifunctional catalyst: Weigh a certain amount of conductive graphene, ultrasonically disperse it in anhydrous methanol, and measure the ZIF-67 prepared above, add it to the above solution and ultrasonically for 10min, then weigh a certain amount A certain amount of thioacetamide is dissolved in absolute ethanol, the mass ratio of the thioacetamide to the cobalt nitrate hexahydrate in step (1) is 1:3.5, and slowly added to the above m...

Embodiment 1

[0028] A preparation method of a sulfur-doped bifunctional oxygen catalyst based on ZIF-67 and conductive graphene:

[0029] (1) Preparation of precursor ZIF-67: Weigh 1.75g of cobalt nitrate hexahydrate and 3.2g of dimethylimidazole, dissolve them in 20mL of anhydrous methanol respectively, mix the above solutions evenly and sonicate for 15min, and mix the sonicated The solution was allowed to stand for 6 hours, and the precipitate was collected, washed with anhydrous methanol several times, and then dispersed in 20 mL of absolute ethanol for later use, which was designated as ZIF-67.

[0030] (2) Co. 9 S 8 Preparation of / S-GN bifunctional catalyst: Weigh 0.02g of conductive graphene, ultrasonically disperse it in 10mL of anhydrous methanol, measure 10mL of ZIF-67 and add it to the above solution for 10min, then weigh 0.5g of thioacetamide solution In 10mL of absolute ethanol, and slowly added to the above mixed solution, stirred for 5min. Heat the uniformly stirred mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com