Negative electrode with carbon-based thin film, manufacturing method therefor, and lithium secondary battery comprising same

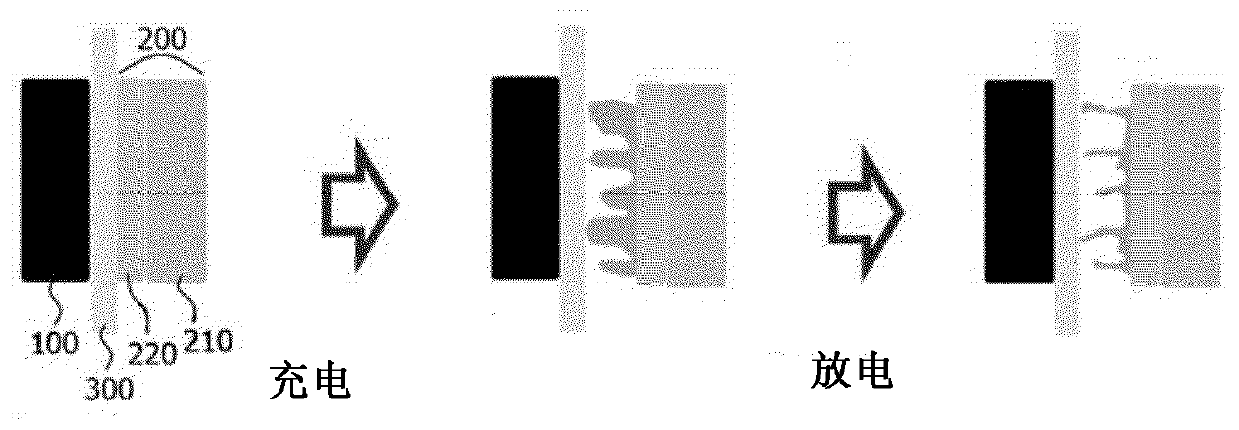

A lithium secondary battery, negative electrode technology, applied in electrode manufacturing, lithium storage battery, negative electrode and other directions, can solve the problems of lithium dendrite stability and performance degradation, improve electrochemical performance, increase specific surface area, uniform current density The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

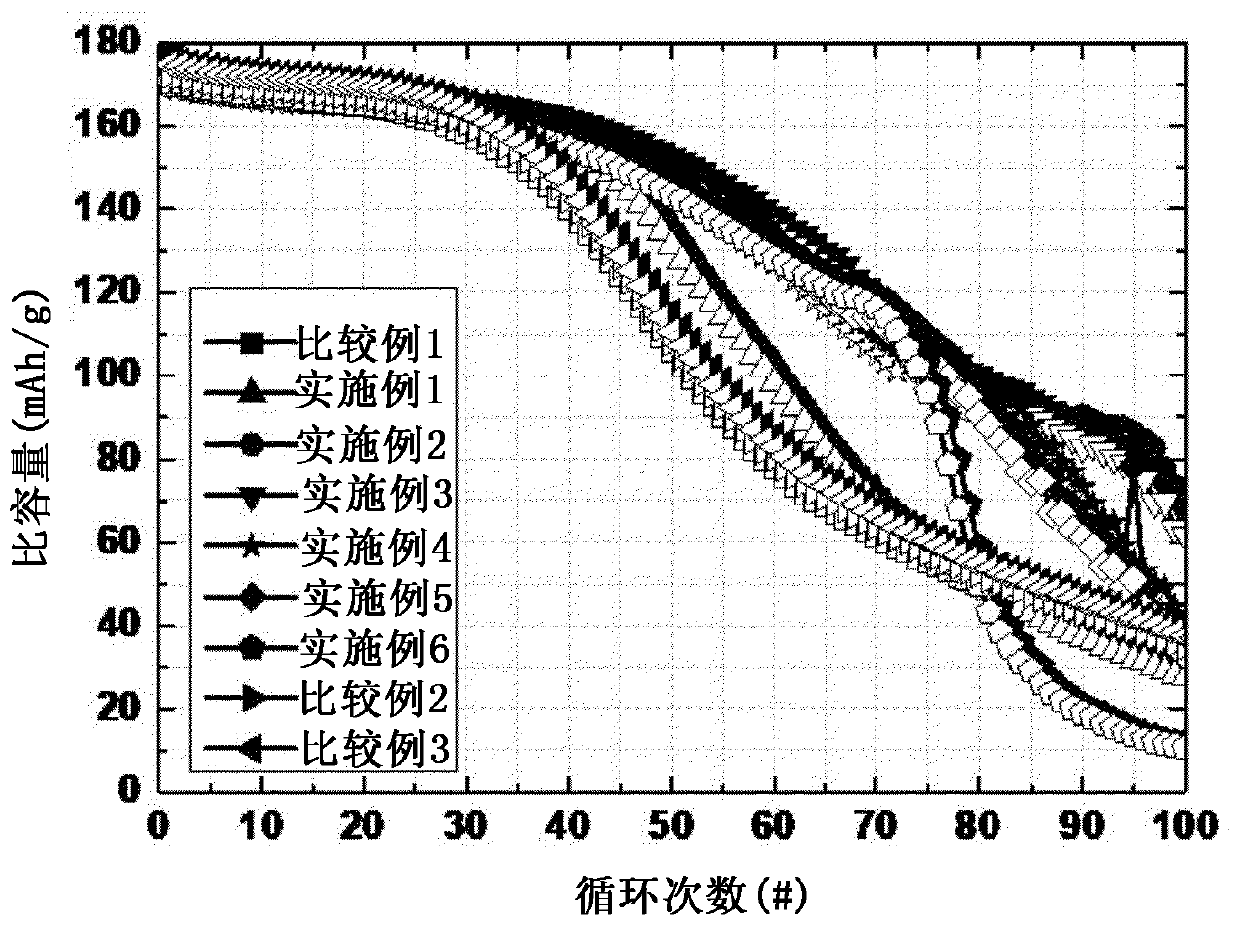

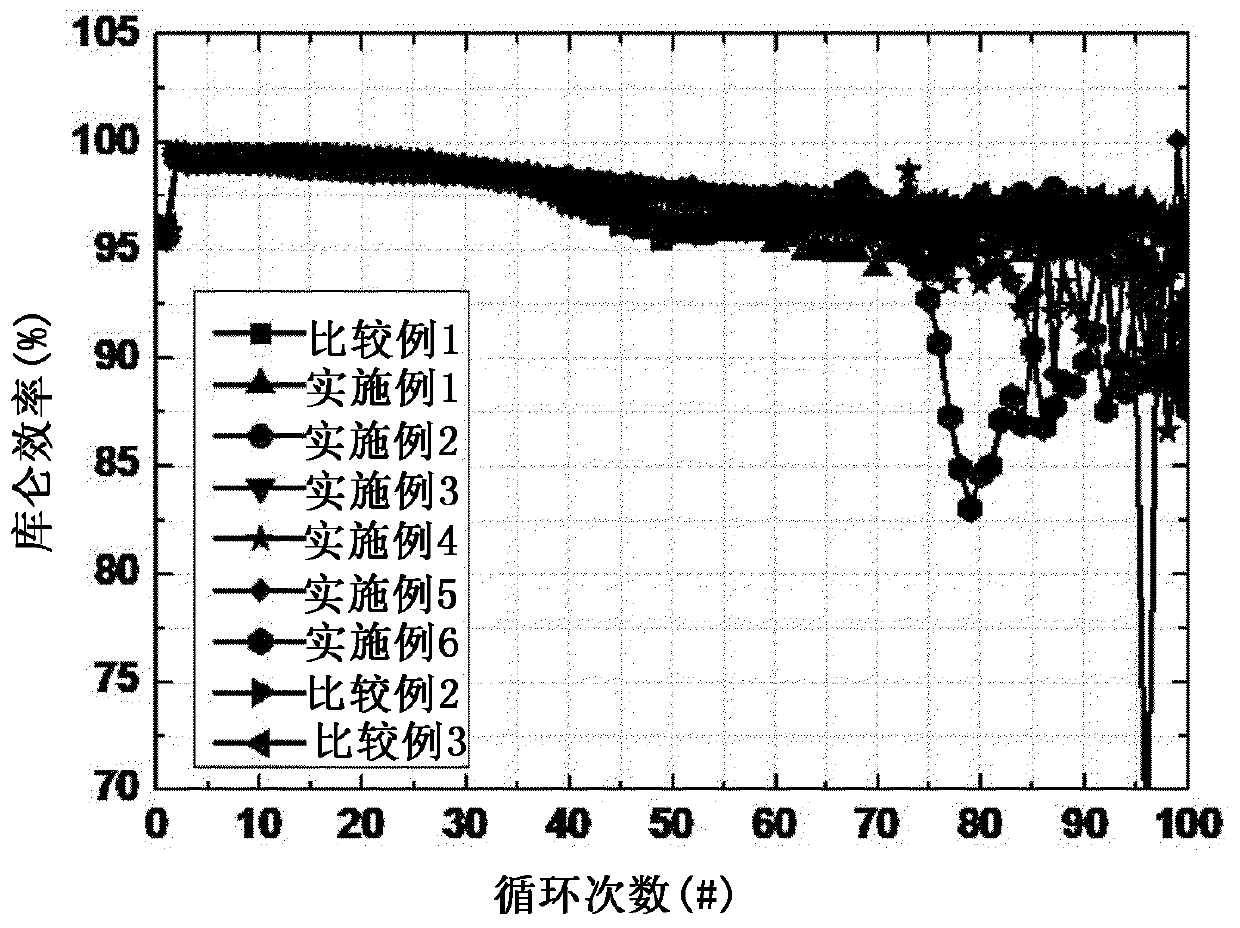

Embodiment 1

[0097] 1) Manufacture of negative electrode

[0098] On the surface of a lithium foil with a thickness of 150 μm, a carbon-based thin film was deposited by RF sputtering for 20 minutes under the following conditions to fabricate a negative electrode.

[0099] Target diameter: 2" diameter

[0100] Substrate-target distance: 5cm

[0101] Gas for sputtering: Ar

[0102] Gas pressure for sputtering: 0.75 mTorr

[0103] Introducing flow rate of gas for sputtering: 500sccm

[0104] Sputtering power density: 8.5W / cm 2

[0105] AC voltage frequency applied to electrodes: 40kHz

[0106] 2) Manufacture of lithium secondary batteries

[0107] Lithium cobalt oxide (LCO) was used as a working electrode, and the negative electrode prepared in 1) was used as a counter electrode. After placing the polyolefin separator between the electrodes, inject it with 1M LiPF 6 An electrolytic solution prepared by dissolving in a solvent of ethylene carbonate (EC) and ethyl methyl carbonate (EMC...

Embodiment 2

[0111] A negative electrode, a lithium secondary battery, and a lithium symmetric battery were fabricated in the same manner as in Example 1 except that the deposition was performed for 40 minutes.

Embodiment 3

[0113] A negative electrode, a lithium secondary battery, and a lithium symmetric battery were fabricated in the same manner as in Example 1 except that the deposition was performed for 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Membrane thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap