Preparation method of metal and plastic composite non-stick pan cooking utensil realizing balanced heat conduction and far-infrared synergism

A far-infrared, non-stick pan technology, used in kitchen utensils, home utensils, special materials for cooking utensils, etc., can solve the problems of poor thermal conductivity and uneven heating, and achieve the effect of improving heat release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Choose the aluminum and aluminum alloy materials that meet the requirements of GB / T 11333, and the rice cooker liner after the cleaning and passivation process.

[0028] The composite material selects a graphene-based heat-conducting far-infrared synergistic primer, which consists of the following raw materials in parts by mass (wt%): 50 parts of D-100 water-based ceramic resin, 10 parts of PPS micropowder, 5 parts of BMI micropowder, and pigment carbon black 3 parts, 25 parts of 5% graphene dispersion slurry, 5 parts of ZX-Y far-infrared ceramic powder, 0.5 parts of BYK-180 wetting and dispersing agent, 0.25 parts of BD-3062 defoamer, 0.25 parts of BD-2051 leveling agent , 0.5 parts of Pangel S9 hydrated magnesium silicate, and 0.5 parts of Degussa's A200 fumed silica.

[0029] When using the primer, use deionized water as the diluent, adopt electrostatic coating process, adjust the spraying viscosity (coating -4 cups) to 16-18s, and spray it on the inner wall surface ...

Embodiment 2

[0033] Choose stainless steel or steel pots and kitchen utensils. The material should meet the requirements of relevant national regulations and standards. The painted surface must be treated by shot blasting or sandblasting.

[0034] The composite material selects a graphene-based heat-conducting far-infrared synergistic primer, which consists of the following raw materials in parts by mass (wt%): 50 parts of D-100 water-based ceramic resin, 10 parts of PPS micropowder, 5 parts of BMI micropowder, and pigment carbon black 3 parts, 25 parts of 5% graphene dispersion slurry, 5 parts of ZX-Y far-infrared ceramic powder, 0.5 parts of BYK-180 wetting and dispersing agent, 0.25 parts of BD-3062 defoamer, 0.25 parts of BD-2051 leveling agent , 0.5 parts of Pangel S9 hydrated magnesium silicate, and 0.5 parts of Degussa's A200 fumed silica.

[0035] The coating topcoat is made of graphene-based thermally conductive far-infrared synergistic non-stick coating, which is composed of the ...

Embodiment 3

[0038] Aluminum and aluminum alloy material pots and stainless steel or steel pot kitchen utensils have the same process and technical requirements for the surface treatment of the outer wall as for the inner surface treatment. The coating material for the outer wall composite material of pots and kitchen utensils is water-based organosilicon heat-resistant protective coating. Aluminum products are directly coated with a colored topcoat, dried and cured at 200-220°C / 15-30 minutes to form a film. The dry film thickness is required to reach 30±10μm. For steel products, first pre-coat a silicone anti-rust primer, flash dry at room temperature for 15-20 minutes, then apply a top coat, dry and solidify at 200-220°C / 15-30 minutes to form a film. The composite coating requires a dry film thickness of 40±10μm. .

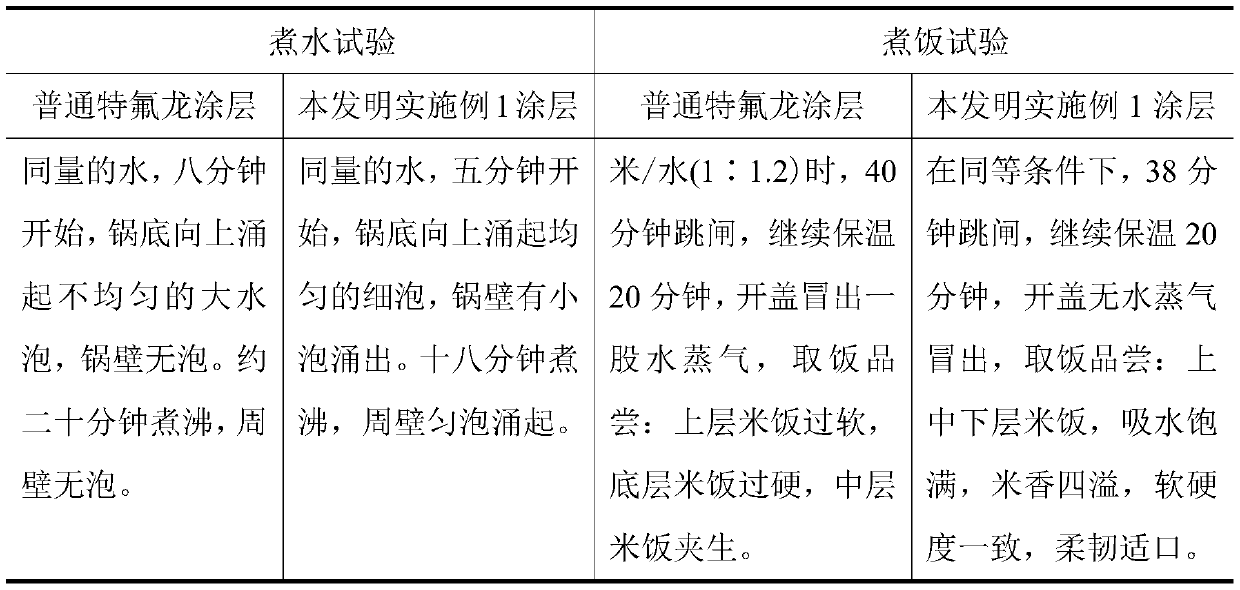

[0039] Through the implementation of the above embodiment 1 and embodiment 3 or embodiment 2 and embodiment 3, the complete and balanced heat conduction far-infrared exot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com