A method for preparing nanoemulsions using supergravity technology

A nanoemulsion and supergravity technology, which is applied in the fields of food, cosmetics and biomedicine, can solve problems such as uneven droplets and complicated operations, and achieve the effects of simple process, low dosage, and reduced toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing nanoemulsions by using high gravity technology, comprising the steps of:

[0042] Mix 10g glycerol triacetate, 3g polyoxyethylene hydrogenated castor oil, and 1.5g 1,2-propanediol by vortexing completely, turn on the high-gravity rotating bed at a speed of 500rpm, and feed the mixed solution at 20ml / min and the aqueous solution at 200ml / min. The temperature of the system is controlled at 25° C., and after the feeding of the mixed solution is completed, the high-gravity rotating bed is closed to obtain a nanoemulsion.

[0043] The consumption of surfactant accounts for 4% of nanoemulsion total amount in the nanoemulsion that present embodiment makes;

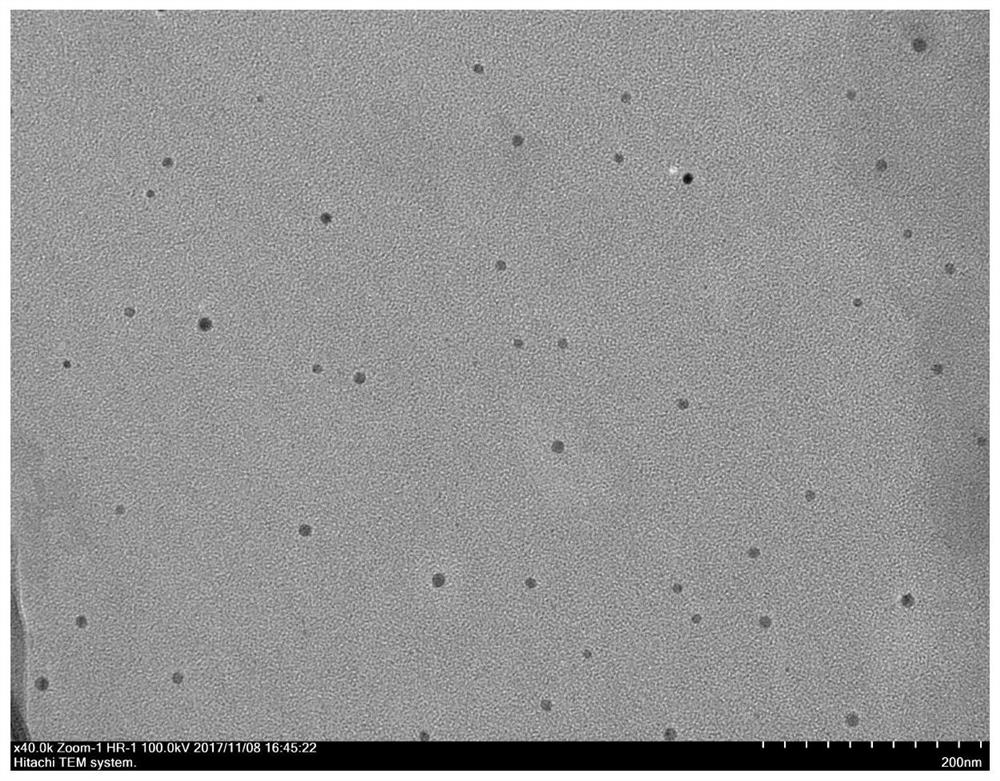

[0044] The appearance of the nanoemulsion prepared in this example is clear and transparent, the average particle size is 15nm; the PDI value of the particle size distribution coefficient is 0.069, indicating that an emulsion with uniform size is obtained. After testing, it was found that after stor...

Embodiment 2

[0050] A method for preparing nanoemulsions by using high gravity technology, comprising the steps of:

[0051] Mix 10g glycerol triacetate, 0.3g polyoxyethylene hydrogenated castor oil, and 0.15g 1,2-propanediol by vortexing completely, turn on the high-gravity rotating bed at a speed of 500rpm, mix the solution at 20ml / min, and the aqueous solution at 200ml / min For feeding, the temperature of the system is controlled at 25° C., and after the feeding of the mixed solution is completed, the high-gravity rotating bed is closed to obtain a nanoemulsion.

[0052] The consumption of surfactant accounts for 0.4% of the nanoemulsion total amount in the nanoemulsion that present embodiment makes;

[0053] The appearance of the nanoemulsion prepared in this example is clear and transparent, the average particle size is 15 nm, and the PDI value of the particle size distribution coefficient is 0.069, indicating that an emulsion with uniform size is obtained. After a long-term stability...

Embodiment 3

[0059] A method for preparing nanoemulsions by using high gravity technology, comprising the steps of:

[0060] Mix 10g of soybean oil, 4g of polyoxyethylene hydrogenated castor oil, and 2g of anhydrous ethanol by vortex shaking, turn on the high-gravity rotating bed at a speed of 1000rpm, feed the mixed solution at 30ml / min, and the aqueous solution at 300ml / min, and control the system The temperature is 25° C., and after the feeding of the mixed solution is completed, the high-gravity rotating bed is closed to obtain a nanoemulsion.

[0061] The consumption of surfactant accounts for 5% of nanoemulsion total amount in the nanoemulsion that present embodiment makes;

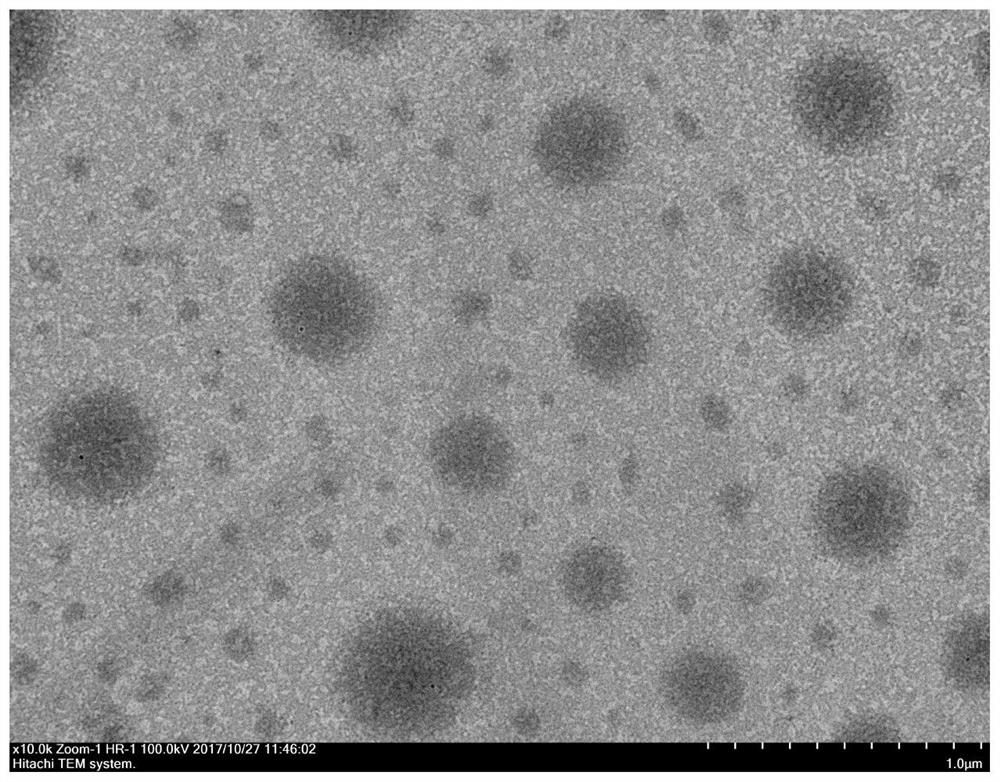

[0062] The appearance of the nanoemulsion prepared in this example is clear and transparent, the average particle size is 25nm, and the PDI value of the particle size distribution coefficient is 0.088, indicating that an emulsion with uniform size is obtained. After a long-term stability test, it was found that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com