Double-layer core-shell structure cast tungsten carbide particle weld wire and preparation method

A technology of tungsten carbide particles and core-shell structure, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems affecting the wear resistance of the surfacing layer, poor high temperature oxidation resistance, and serious particle decomposition, etc., to achieve weldable Good durability, not easy to decompose, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method for casting tungsten carbide particle welding wire with a double-layer core-shell structure, comprising the following steps:

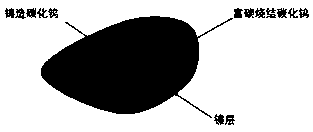

[0032] 1) The main component of cast tungsten carbide is WC / W 2 C p , the cast tungsten carbide particles are subjected to the surface carburizing process through 1~10% nano-carbon black, and the carburized cast tungsten carbide is mixed with alloy powder and mechanical binder, and then heated to 1500~1900°C for sintering under vacuum. Insulate for 1-2 hours to obtain double-layer core-shell structure tungsten carbide. After modification, carbon-rich sintered tungsten carbide and nickel-based shells will be formed outside the particles, with an average thickness of 3-12 μm, and double-layer core-shell structure cast tungsten carbide particles will be obtained. welding core;

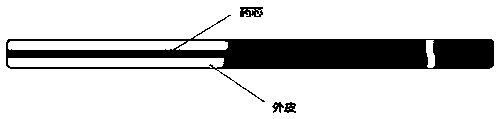

[0033] 2) In step 1), the cast tungsten carbide particle welding core with double-layer core-shell structure is covered with seam coating or seamless...

Embodiment 1

[0037] The outer skin is made of nickel alloy (ERNiCrMo alloy), and the composition of the drug core is: cast tungsten carbide particles, according to the particle size ratio of 20-50 mesh, the proportion is 30%, and the proportion of 50-200 mesh is 70%. The proportion of cast tungsten carbide is 70%, the mixture of ferromanganese powder, nickel powder, niobium powder and ferrosilicon powder is 28%, organic resin is 2%, and the weight ratio of filler is 70~80%. Among them, the effect is the best when spherical nickel powder is used as the binder. The result of the three-body wear test of SiC particles in this embodiment shows that the wear resistance of the clad wear-resistant layer is 30-40% higher than that of the existing similar welding wire.

Embodiment 2

[0039] The outer skin is made of copper alloy, and the composition of the drug core is: cast tungsten carbide particles, according to the particle size ratio of 20-50 mesh, the proportion is 35%, and the proportion of 50-200 mesh is 65%. The proportion of cast tungsten carbide is 80%, the mixture of ferromanganese powder, nickel powder, niobium powder and ferrosilicon powder is 19%, organic resin is 1%, and the weight ratio of filler is 70~80%. Among them, the effect is the best when spherical nickel powder is used as the binder. The results of the three-body wear test of SiC particles in this embodiment show that the wear resistance of the clad wear-resistant layer is 20-40% higher than that of the existing similar welding wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com