Method for photochemically preparing nano selenium

A nano-selenium and photochemical technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of inhomogeneity of nano-selenium particles, complex phase separation in the later stage, and strict reaction conditions, etc., to achieve Easy-to-master control, high industrial application prospects, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

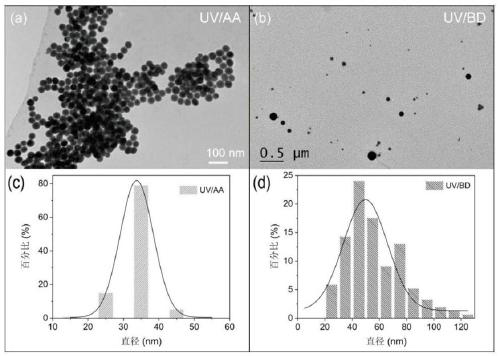

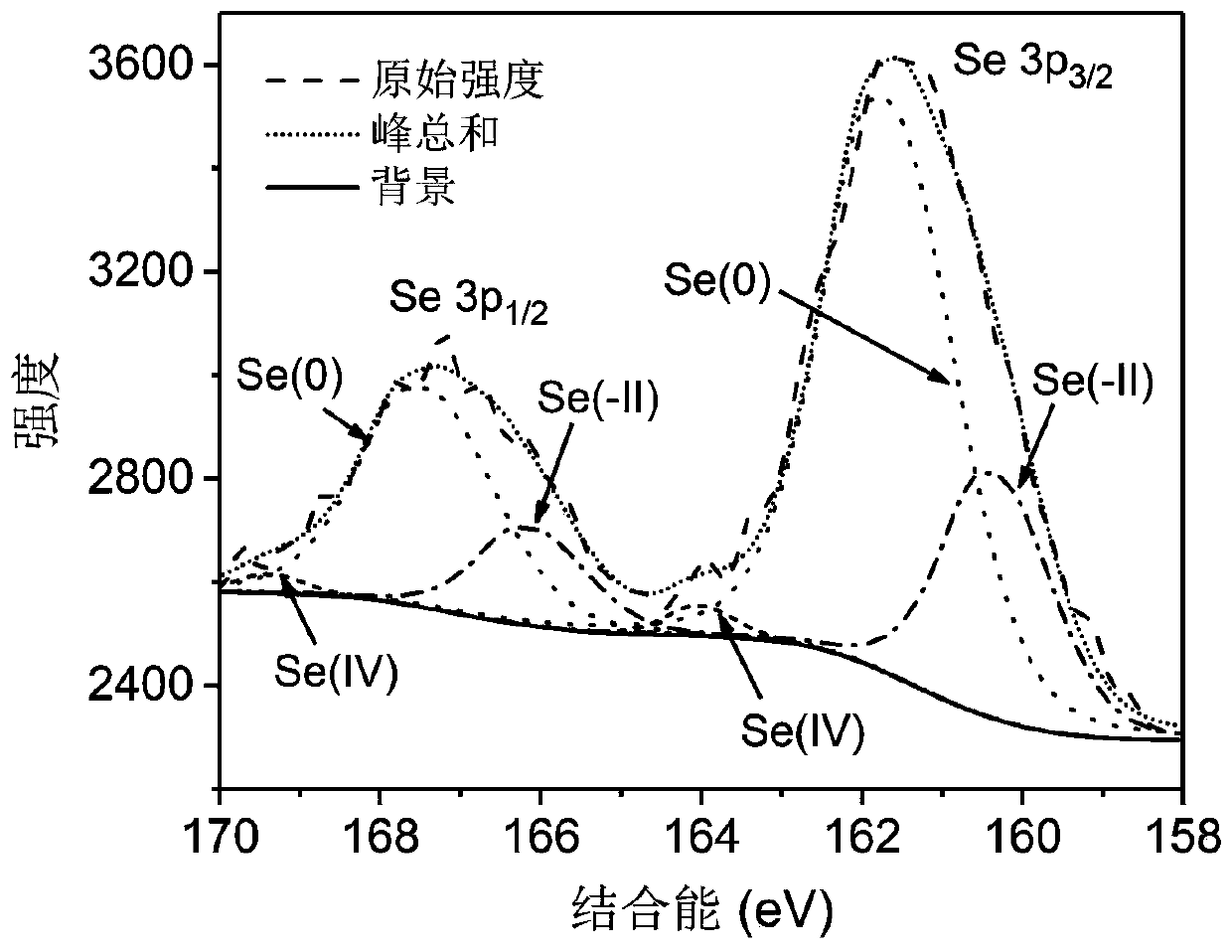

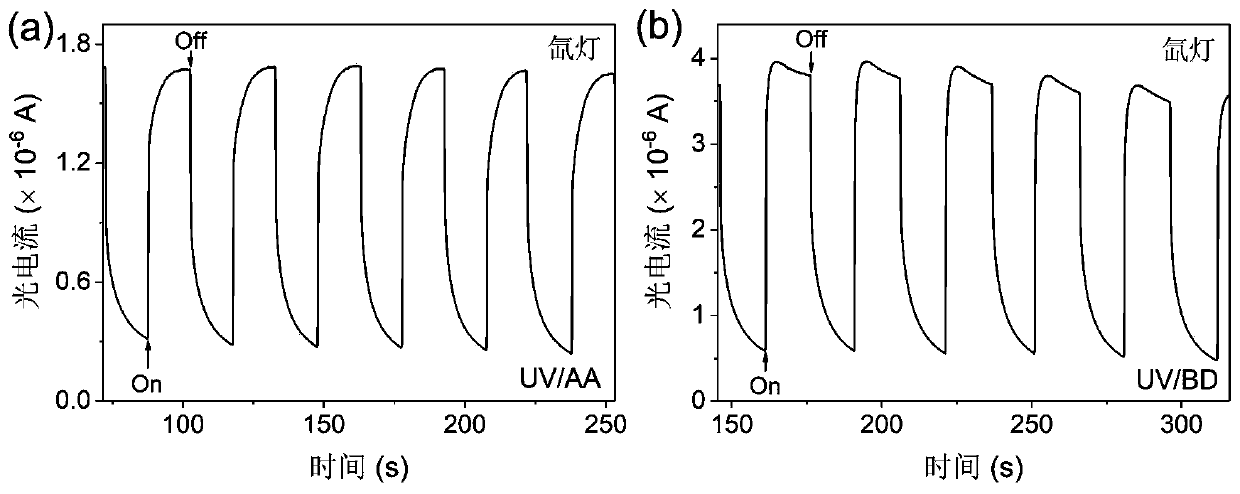

[0037] Embodiment 1 photochemical reaction prepares nano selenium

[0038] Set the molar ratio of sodium selenite to AA (or BD) at 1:5, take 0.5mL of 10mM sodium selenite and 5mL of 5mM AA (or BD) solution, and add them to a glass colorimetric tube with a volume of 25mL , add ultrapure water to dilute to the mark, shake evenly, that is, 0.2mM selenite, 1.0mM AA or BD.

[0039] Then pour into a 25mL quartz photoreaction tube, and finally put the reaction tubes into the photoreactor one by one. The light intensity of the reaction is 13.5mW / cm 2 , and respectively illuminate the corresponding AA-containing solution for 70 minutes, and the solution of BD for 40 minutes to obtain a uniform red elemental selenium colloidal mixture.

[0040] Centrifuge the red colloid mixture (10000rpm, centrifuge for 30min), remove the supernatant, add ultrapure water to wash and then centrifuge, after repeating this three times, freeze-dry the obtained colloidal nano-selenium (-50°C, 0.120mBar, d...

Embodiment 2

[0044] Example 2 The influence of selenite concentration on the preparation of nano-selenium by UV / AA method reduction of selenite

[0045] Set the molar concentration of AA to 1.0mM, and the molar ratios of sodium selenite and AA to 1:10 and 1:5, respectively. Take 0.25 and 0.5mL of 10mM sodium selenite solution, 5mL of 5mM Add the AA solution into a glass colorimetric tube with a volume of 25mL, add ultrapure water to dilute to the mark, and oscillate evenly to obtain 0.1 and 0.2mM selenite solutions and 1.0mMAA respectively. Then pour into a 25mL quartz photoreaction tube, and finally put the reaction tubes into the photoreactor one by one. The light intensity of the reaction is 13.5mW / cm 2 , light reaction for 120min, sampling once every 5min to detect the concentration of selenite.

[0046] Figure 4 It is a schematic diagram of the change of selenite concentration in this embodiment. When the concentration of AA is constant and the concentration of selenite is 0.1mM,...

Embodiment 3

[0047] Example 3 Effect of Diketone Concentration on the Preparation of Nano-Selenium by UV / Diketone Method Reduction of Selenite

[0048] The molar concentration of sodium selenite is set to 0.2mM, the molar ratio of sodium selenite and AA or BD is set at 1:5, 1:10 and 1:15, take 0.5mL of 10mM sodium selenite solution, 5. Add 10 or 15mL of 5mM AA (or BD) solution into a glass colorimetric tube with a volume of 25mL, add ultrapure water to dilute to the mark, and oscillate evenly to obtain 0.2mM selenite, 1.0, 2.0 and 3.0 mM AA or BD. Then pour into a 25mL quartz photoreaction tube, and finally put the reaction tubes into the photoreactor one by one. The light intensity of the reaction is 13.5mW / cm 2 , light reaction for 80min, sampling once every 10min to detect the concentration of selenite.

[0049] Figure 5 It is a schematic diagram of the change of selenite concentration in this embodiment. Under the same conditions, the sequence of conversion effects of different p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com