Polyurethane foam with good thermal insulation property and preparation method thereof

A technology of polyurethane foam and thermal insulation, applied in the field of foam, can solve the problems of unsatisfactory thermal insulation, poor sound absorption and damping performance, poor water resistance, etc., achieve excellent anti-vibration performance, excellent elasticity, and expand the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

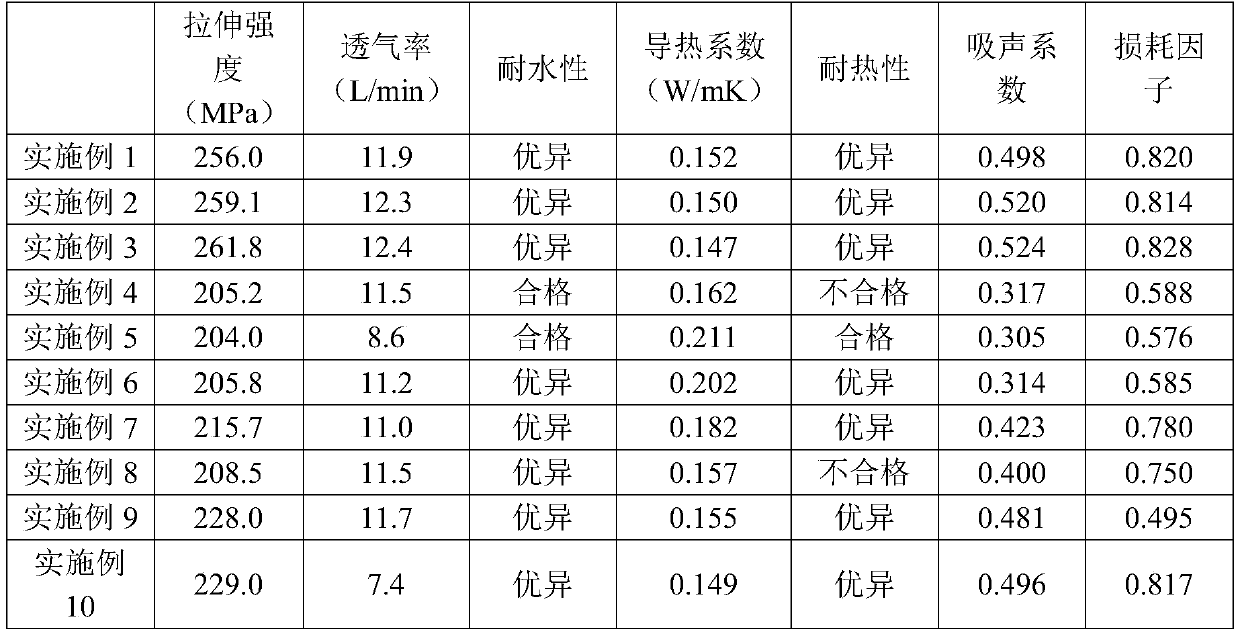

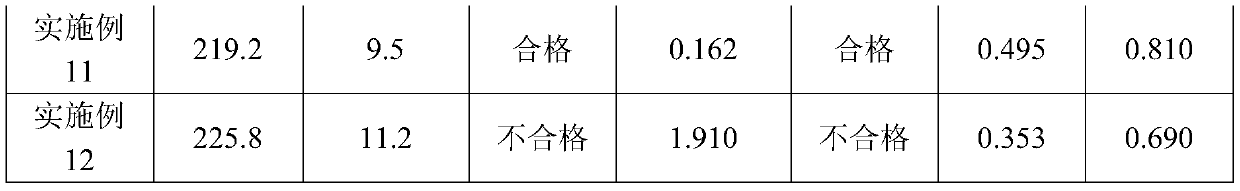

Examples

preparation example Construction

[0027] In one embodiment, the preparation method of the soybean oil polyol comprises the following steps:

[0028] (1) Add soybean oil and maleic anhydride into a four-necked flask, heat up to 190-210°C, and react for 2-3 hours to obtain the intermediate maleic anhydride-modified soybean oil;

[0029] (2) Add maleic anhydride-modified soybean oil, diethylene glycol and KOH into a four-neck flask, heat up to 190-220°C, and react for 5-6 hours to obtain crude soybean oil polyol;

[0030] (3) Add crude soybean oil polyol in a four-neck flask, remove unreacted diethylene glycol through repeated washing and liquid separation; add 3wt% water, and phosphoric acid with a mass concentration of 98% to neutralize KOH, 0.3wt % magnesium silicate adsorbent, water is removed by vacuum distillation, and adsorbent and potassium salt are removed by suction filtration.

[0031] Preferably, the maleic anhydride accounts for 0.25-0.4 wt% of the soybean oil; more preferably, the maleic anhydride ...

Embodiment 1

[0087] Embodiment 1 of the present invention provides a polyurethane foam with good thermal insulation. In parts by weight, the preparation raw materials of the polyurethane foam include 60 parts of polyester polyol, 15 parts of polyether polyol, 15 parts of airgel, 5 parts of Parts of blowing agent, 0.5 parts of foam stabilizer, 0.5 parts of catalyst, 0.75 parts of water, 65 parts of polyisocyanate, 2.5 parts of flame retardant.

[0088] The polyester polyol is a vegetable oil polyol; the vegetable oil polyol is a soybean oil polyol; the polyether polyol is purchased from Guangzhou Yinghong Chemical Co., Ltd., and the model is Puranol D204; the airgel includes two Silica airgel and amino-modified alumina / silica airgel; the weight ratio of the silica airgel and amino-modified alumina / silica airgel is 3:1; The blowing agent is 1,1,1,4,4,4-hexafluorobutene; the foam stabilizer is silicone oil; the catalyst includes triethanolamine and T-9; the triethanolamine and T-9 The weight...

Embodiment 2

[0100] Embodiment 2 of the present invention provides a kind of polyurethane foam with good thermal insulation, and by weight, the preparation raw material of described polyurethane foam comprises 60 parts of polyester polyols, 35 parts of polyether polyols, 10 parts of airgel, 10 parts of 1 part blowing agent, 2 parts foam stabilizer, 1 part catalyst, 1.6 parts water, 75 parts polyisocyanate; 5 parts flame retardant.

[0101] The polyester polyol is a vegetable oil polyol; the vegetable oil polyol is a soybean oil polyol; the polyether polyol is purchased from Guangzhou Yinghong Chemical Co., Ltd., and the model is Puranol G307; the airgel includes two Silica airgel and amino-modified alumina / silica airgel; the weight ratio of the silica airgel and amino-modified alumina / silica airgel is 6:1; The blowing agent is 1,1,1,4,4,4-hexafluorobutene; the foam stabilizer is silicone oil; the catalyst includes triethanolamine and T-9; the triethanolamine and T-9 The weight ratio is 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com