Conductive polyaniline blend fiber and preparation method and application thereof

A technology of conductive polyaniline and blended fibers, which is applied in the manufacture of conductive/antistatic filaments, wet spinning, and conjugated synthetic polymer artificial filaments. It can solve the problems of low conductivity, poor mechanical properties, and easy mixing of solutions. Gel and other problems, to achieve the effect of high conductivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A conductive polyaniline blend fiber, including polyvinylpyrrolidone, polyaniline, and anticoagulant tetrahydropyrrole, and the preparation method is as follows:

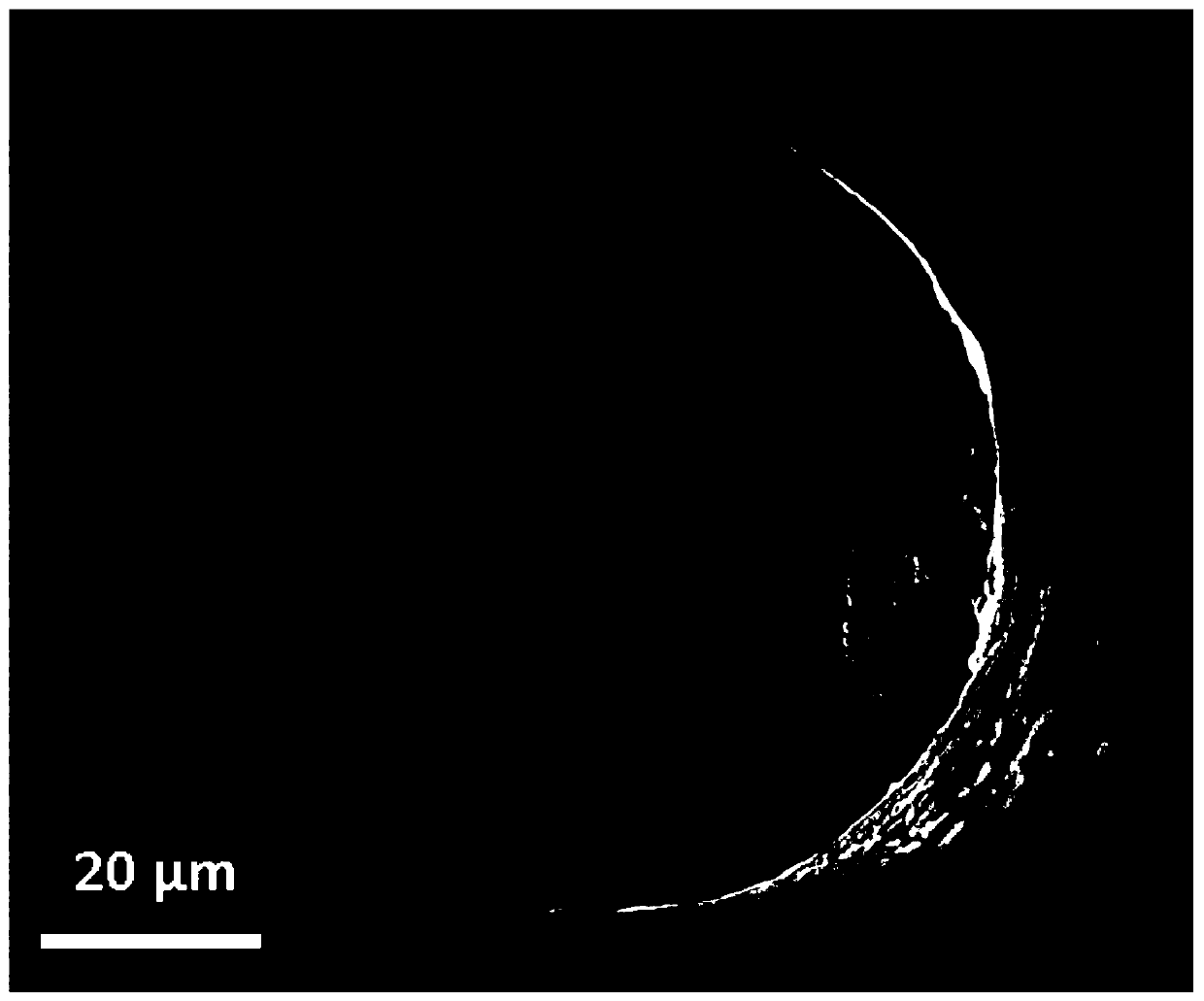

[0058] (1) Add 2g of PVP to the N-methylpyrrolidone (19g) solvent with 1g of anticoagulant tetrahydropyrrole (the ratio of the substance to polyaniline is 1:1), and use a three-necked flask Mechanical stirring, under nitrogen atmosphere, add 3g of ball-milled polyaniline powder (D90≤10μm) to ensure that the bottle is always in an oxygen-free and water-free environment during the entire experiment. Stir continuously for 2h at 25℃ to obtain 20wt %PANI+5wt%PVP polystyrene / polyaniline spinning stock solution.

[0059] (2) After filtering the spinning dope with a 200 mesh filter cloth to obtain the filtrate, add it to the spinning equipment for wet spinning, the nozzle diameter is 0.075mm, the coagulation bath solvent is 10% NMP solution, and the coagulation bath temperature is 5°C ; After the silk is discharged, the ...

Embodiment 2-3

[0062] The only difference from Example 1 is that PVP is replaced with polyacrylonitrile (Example 2) and polystyrene (Example 3).

Embodiment 4

[0064] The only difference from Example 1 is that the addition amount of PVP is 1 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com