Coupling structure and coupling method of semiconductor laser chip and silicon optical chip

A technology of silicon optical chip and coupling structure, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of unable to meet the needs of high power and high performance of light sources, low light output power of silicon-based light sources, complex processes, etc., to achieve Effects of reducing light field scattering loss, reducing light reflection, and flexible coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention also discloses a preparation method of the coupling structure as described above, which includes the following steps:

[0047] (1) setting an etching groove for coupling with the laser chip in the laser unit on the coupling end face of the silicon photonic chip to obtain a silicon photonic chip one;

[0048] (2) Set up spacers on the substrate of the laser unit where the silicon photonic chip needs to be connected;

[0049] (3) After aligning the active area of the laser chip with the waveguide of silicon photonic chip 1, set a refractive index matching glue between the etching groove of the silicon photonic chip and the laser chip, and place it between the spacer and the silicon photonic chip Fixing glue is set to fix, and the coupling structure is obtained.

[0050] Wherein, the etching groove described in the step (1) is formed by a deep etching process;

[0051] Wherein, the laser unit described in step (2) comprises a substrate, a heat sink arrang...

Embodiment

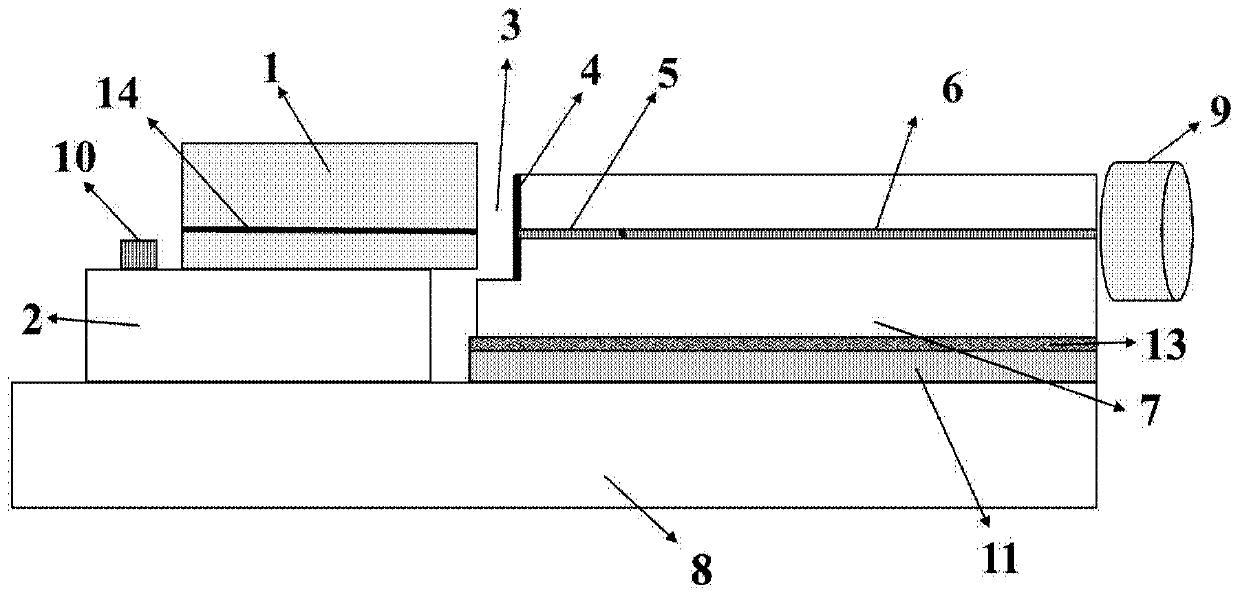

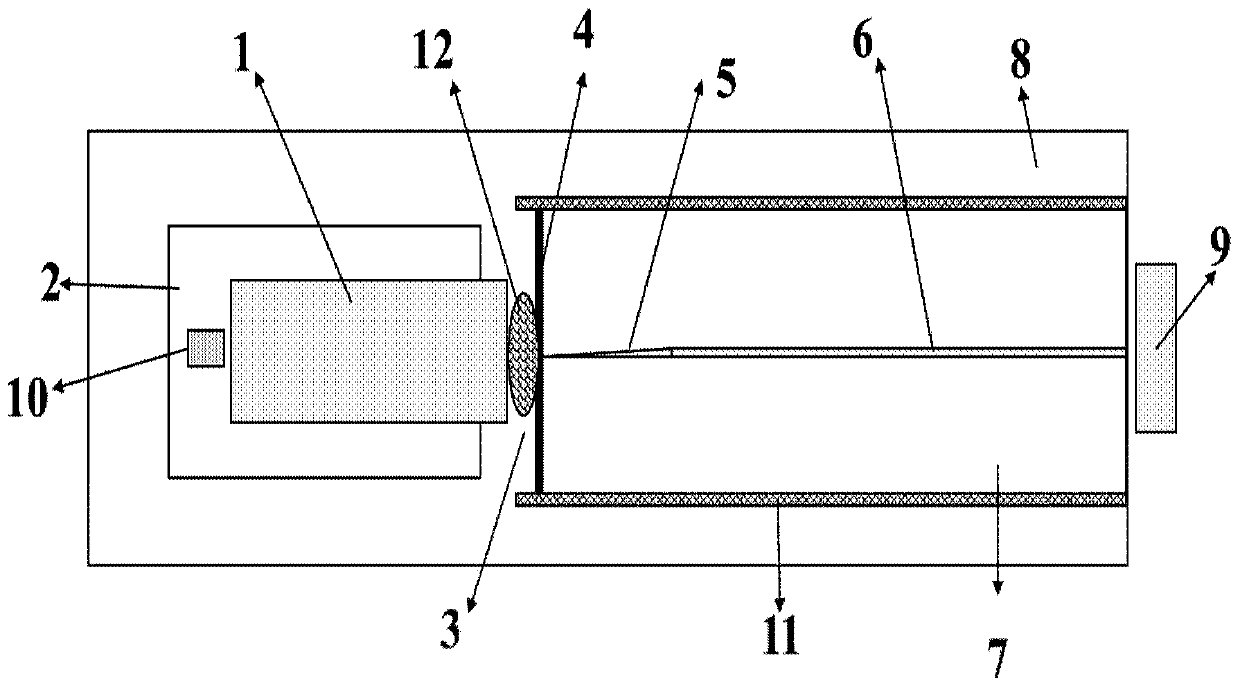

[0083] Such as figure 1 with figure 2 As shown, this embodiment provides a high-efficiency and low-loss coupling structure between a semiconductor laser chip and a silicon photonic chip, which includes a semiconductor laser chip 1 and a silicon photonic chip 7, wherein the silicon photonic chip 7 has a mode field conversion structure 5 And the waveguide structure 6 (including active and passive structures) on the silicon photonics chip 7 , heat sink 2 , thermistor 10 , spacer 11 , TEC substrate 8 , and high-sensitivity large-area detector 9 . The following are high-efficiency coupling methods and process implementation steps.

[0084] Step 1: Fabricate a silicon photonics chip 7 according to a conventional silicon photonics process, wherein the coupling end uses a deep etching process to form an etching groove 3 for end-face coupling, and a speckle conversion structure 5 is prepared at the coupling end, and a speckle conversion structure 5 The specific structure depends on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com