Efficient low-toxicity formaldehyde scavenging agent and preparation method thereof

A formaldehyde scavenger, high-efficiency and low-toxicity technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of reducing formaldehyde removal efficiency, unreachable, and inability to realize formaldehyde scavenger, etc., to facilitate formaldehyde removal work , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

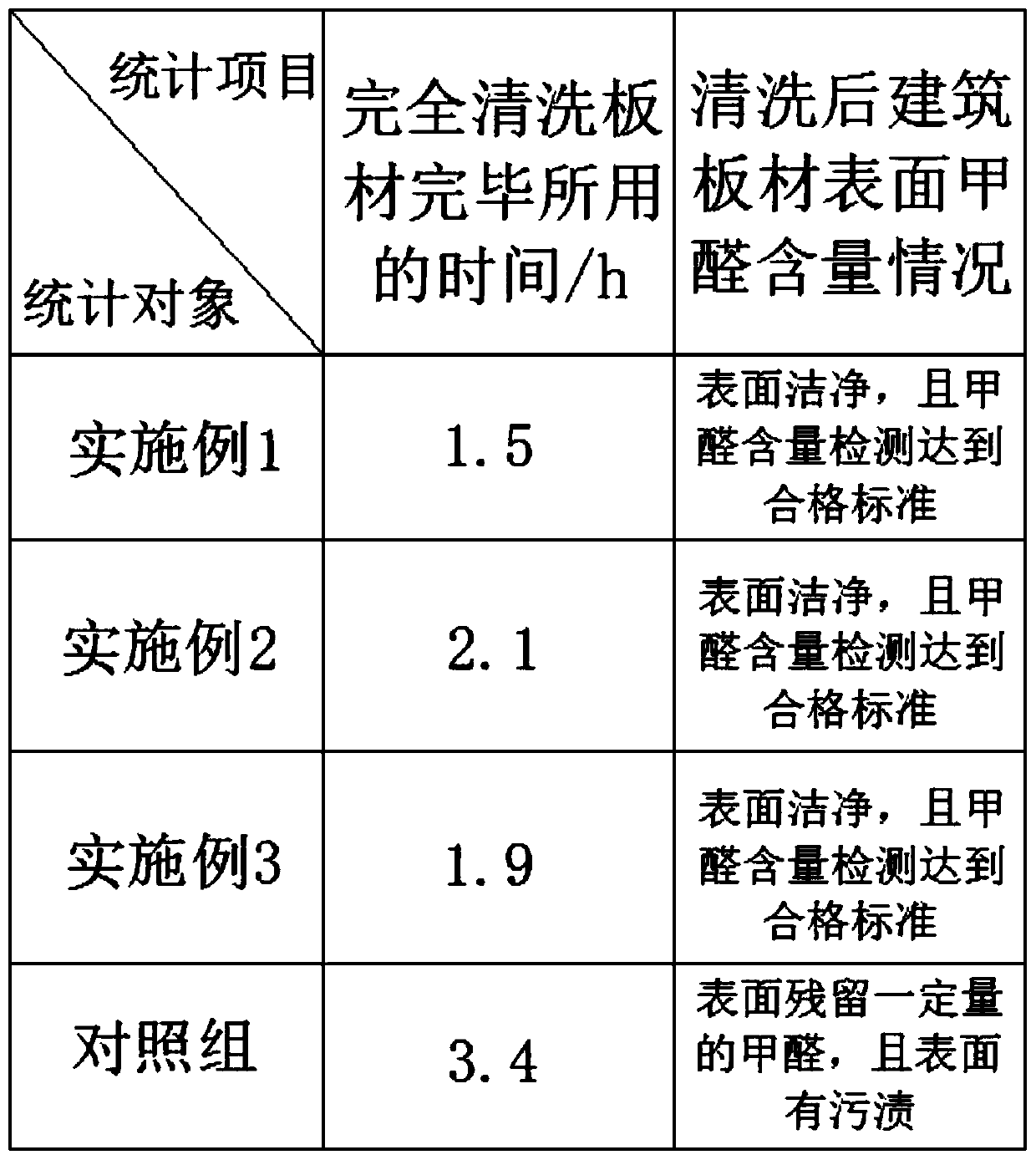

Examples

Embodiment 1

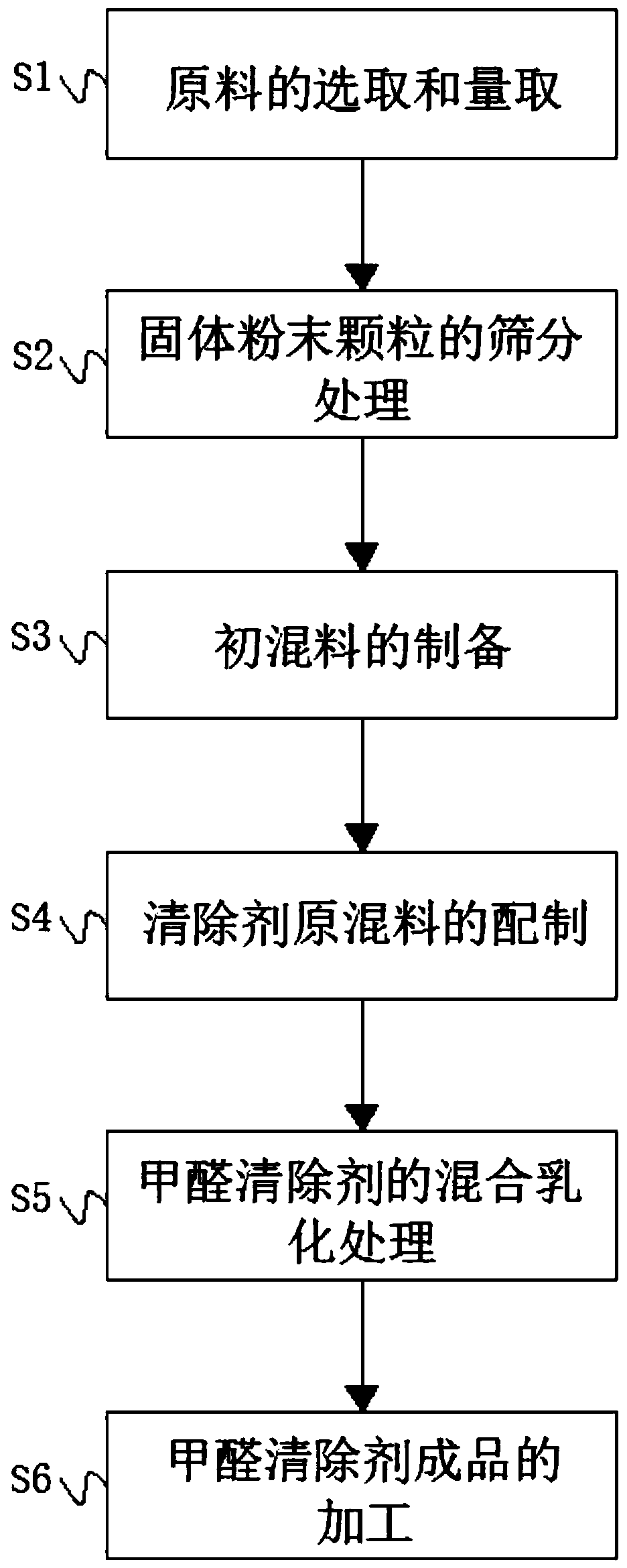

[0030]S1. Selection and measurement of raw materials: First, take 7 parts of nano-anion powder, 7 parts of live ore powder, 7 parts of chrysanthemum extract, 7 parts of activated carbon powder, and 7 parts of active high Molecular composition, 7 parts of begonia extract, 3 parts of ammonium salt composition, 3 parts of organic solvent, 7 parts of aloe extract, 3 parts of penetrant and 3 parts of surfactant, the active polymer composition is composed of chitosan, The mixture of 2-aminoethanol, fatty acid and simethicone, the ammonium salt composition is a mixture of ammonium chloride, ammonium sulfate, ammonium bisulfate, ammonium nitrate and ammonium carbonate, the surfactant is phospholipid, choline , the composition of amino acid, sodium stearyl sulfate and sodium stearate;

[0031] S2. Screening treatment of solid powder particles: Pour the nano-anion powder, live ore powder and activated carbon powder measured in step S1 into the crushing and screening equipment, and first...

Embodiment 2

[0037] S1. Selection and measurement of raw materials: First, measure 5 parts of nano-anion powder, 5 parts of live ore powder, 5 parts of chrysanthemum extract, 5 parts of activated carbon powder, and 5 parts of active high Molecular composition, 5 parts of begonia extract, 5 parts of ammonium salt composition, 5 parts of organic solvent, 10 parts of aloe extract, 5 parts of penetrating agent and 5 parts of surfactant, the active polymer composition is composed of chitosan, The mixture of 2-aminoethanol, fatty acid and simethicone, the ammonium salt composition is a mixture of ammonium chloride, ammonium sulfate, ammonium bisulfate, ammonium nitrate and ammonium carbonate, and the surfactant is phospholipid;

[0038] S2. Screening treatment of solid powder particles: Pour the nano-anion powder, live ore powder and activated carbon powder measured in step S1 into the crushing and screening equipment, and first pass through a 100-mesh screen for screening, and the powder that ca...

Embodiment 3

[0044] S1. Selection and measurement of raw materials: First, take 10 parts of nano-anion powder, 10 parts of live ore powder, 10 parts of chrysanthemum extract, 10 parts of activated carbon powder, and 10 parts of active high Molecular composition, 10 parts of begonia extract, 1 part of ammonium salt composition, 1 part of organic solvent, 5 parts of aloe extract, 1 part of penetrating agent and 1 part of surfactant, the active polymer composition is composed of chitosan, The mixture of 2-aminoethanol, fatty acid and simethicone, the ammonium salt composition is a mixture of ammonium chloride, ammonium sulfate, ammonium bisulfate, ammonium nitrate and ammonium carbonate, and the surfactant is sodium stearate ;

[0045] S2. Screening treatment of solid powder particles: Pour the nano-anion powder, live ore powder and activated carbon powder measured in step S1 into the crushing and screening equipment, and first pass through a 110-mesh screen for screening, and the powder that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com