Method for preparing titanium dioxide from waste honeycomb denitration catalyst

A denitration catalyst and honeycomb technology, which is applied in the field of waste honeycomb denitration catalyst to prepare titanium dioxide, can solve the problems of aggravating the greenhouse effect, cumbersome process flow of by-products, high investment, etc., achieving simple process flow, avoiding excessive consumption, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

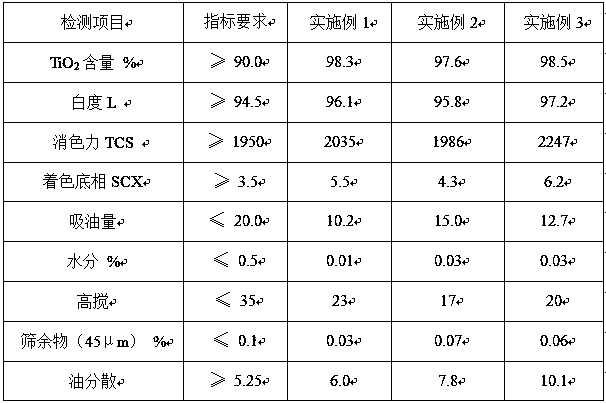

Examples

Embodiment 1

[0030] A method for preparing titanium dioxide from waste honeycomb denitration catalyst, comprising the following steps:

[0031] a. Pretreatment: Mix 1 part of waste honeycomb denitrification catalyst with a titanium dioxide content of 82% and 6 parts of high-titanium slag with a titanium dioxide content of 90% in a certain proportion, use a ray mill to crush and grind until passing through a 325-mesh sieve, and sieve Shangwu 5%;

[0032] b. Acid hydrolysis: use the solid-phase acid hydrolysis method, put the pretreated powder into the acid hydrolysis reaction kettle, add concentrated sulfuric acid, adjust the liquid-solid ratio to 1.75, and use 0.15MPa compressed air to stir, so that the titanium-containing powder and sulfuric acid are fully mixed , the reaction acid concentration is 93%, and the acid hydrolysis time is 3h;

[0033] c. Sedimentation and impurity removal: 700g flocculant / m 3 Proportion of titanium liquid Add flocculant-modified polyacrylamide to the titani...

Embodiment 2

[0038] A method for preparing titanium dioxide from waste honeycomb denitration catalyst, comprising the following steps:

[0039] a. Pretreatment: Mix 1 part of waste honeycomb denitration catalyst with a titanium dioxide content of 85% and 9 parts of high-titanium slag with a titanium dioxide content of 83% in a certain proportion, use a ray mill to crush and grind until passing through a 325-mesh sieve, and sieve Shangwu 7%;

[0040] b. Acidolysis: adopt the solid-phase acidolysis method, put the pretreated powder into the acidolysis reaction kettle, add the waste acid recovered in Example 1, adjust the liquid-solid ratio to 1.9, and use 0.2MPa compressed air to stir to make the The titanium powder is fully mixed with sulfuric acid, the reaction acid concentration is 90%, and the acid hydrolysis time is 2.5h;

[0041]c. Sedimentation and impurity removal: according to 500g flocculant / m 3 Proportion of titanium liquid Add flocculant-modified polyacrylamide to the acid-hydr...

Embodiment 3

[0046] A method for preparing titanium dioxide from waste honeycomb denitration catalyst, comprising the following steps:

[0047] a. Pretreatment: Mix 1 part of waste honeycomb denitrification catalyst with 90% titanium dioxide content and 7 parts of high-titanium slag with 90% titanium dioxide content in a certain proportion, use a ray mill to crush and grind until passing through a 325 mesh sieve, and sieve Shangwu 3%;

[0048] b. Acid hydrolysis: use the solid-phase acid hydrolysis method, put the pretreated powder into the acid hydrolysis reaction kettle, add concentrated sulfuric acid, adjust the liquid-solid ratio to 1.7, and stir with 0.25MPa compressed air to fully mix the titanium-containing powder and sulfuric acid , the reaction acid concentration is 92%, and the acid hydrolysis time is 3h;

[0049] c. Sedimentation and impurity removal: 200g flocculant / m 3 Proportion of titanium liquid Add flocculant-modified polyacrylamide to the acid-hydrolyzed titanium liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com