High silica/phenolic aldehyde material with excellent ablation resistance and heat insulation performance and preparing method thereof

An ablation-resistant, high-silicon-oxygen technology, applied in the field of composite materials, to achieve the effects of improved mechanical properties, small thickness and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

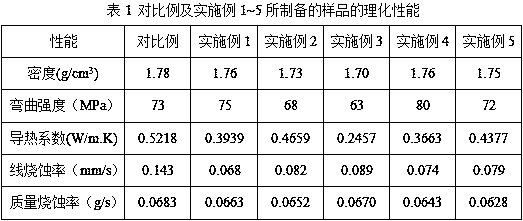

[0013] Raw material components (by mass percentage): boron phenolic resin 38%, high silica fiber 50%, alumina airgel powder 2%, potassium hexatitanate whisker 6%, SiC micropowder 4%;

[0014] Preparation process: Dissolve boron phenolic resin in absolute ethanol at a volume ratio of 1:10, stir and disperse evenly; then add high silica fiber, alumina airgel powder, potassium hexatitanate whisker and SiC micropowder in sequence and stir Disperse evenly; then dry at 60°C for 24 hours, remove the solvent ethanol to obtain a fiber prepreg; finally put the fiber prepreg into a mold, heat press at 200°C and 30MPa, cool, and demould, that is, a good High silica / phenolic composite material with ablation resistance and thermal insulation properties. Its physical and chemical properties are listed in Table 1.

Embodiment 2

[0016] Raw material components (by mass percentage): boron phenolic resin 33%, high silica fiber 56%, silica airgel powder 1%, potassium hexatitanate whisker 8%, SiC micropowder 2%;

[0017] Preparation process: Dissolve boron phenolic resin in absolute ethanol at a volume ratio of 1:15, stir and disperse evenly; then add high silica fiber, alumina airgel powder, potassium hexatitanate whisker and SiC micropowder in sequence and stir Disperse evenly; then dry at 80°C for 24 hours, remove the solvent ethanol to obtain a fiber prepreg; finally put the fiber prepreg into a mold, heat press it at 180°C and 20MPa, cool, and demould, that is, a good High silica / phenolic composite material with ablation resistance and thermal insulation properties. Its physical and chemical properties are listed in Table 1.

Embodiment 3

[0019] Raw material components (by mass percentage): boron phenolic resin 42%, high silica fiber 45%, alumina airgel powder 5%, potassium hexatitanate whisker 3%, SiC micropowder 5%;

[0020] Preparation process: Dissolve boron phenolic resin in absolute ethanol at a volume ratio of 1:12, stir and disperse evenly; then add high silica fiber, alumina airgel powder, potassium hexatitanate whisker and SiC micropowder in sequence and stir Disperse evenly; then dry at 100°C for 24 hours, remove the solvent ethanol to obtain a fiber prepreg; finally put the fiber prepreg into a mold, heat press it at 185°C, 10MPa, cool, and demould, that is, a good High silica / phenolic composite material with ablation resistance and thermal insulation properties. Its physical and chemical properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com