Polyester resin for powder coating and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of formaldehyde and non-compliance with environmental protection requirements, and improve weather resistance, glass transition temperature, and hardness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

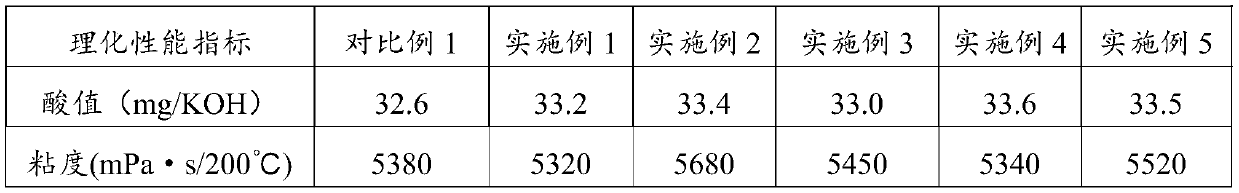

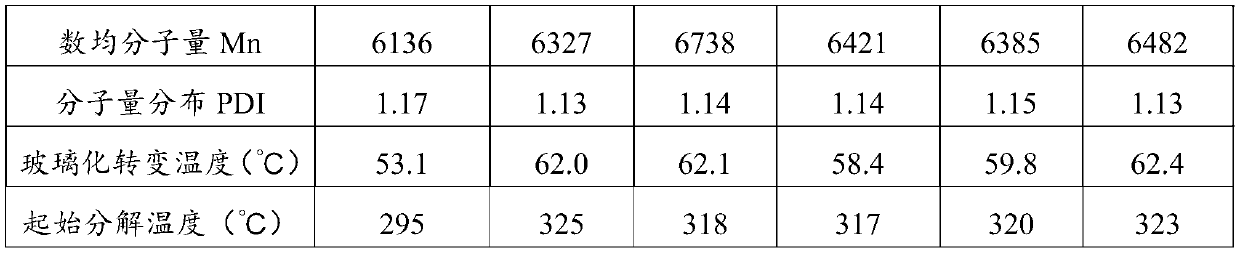

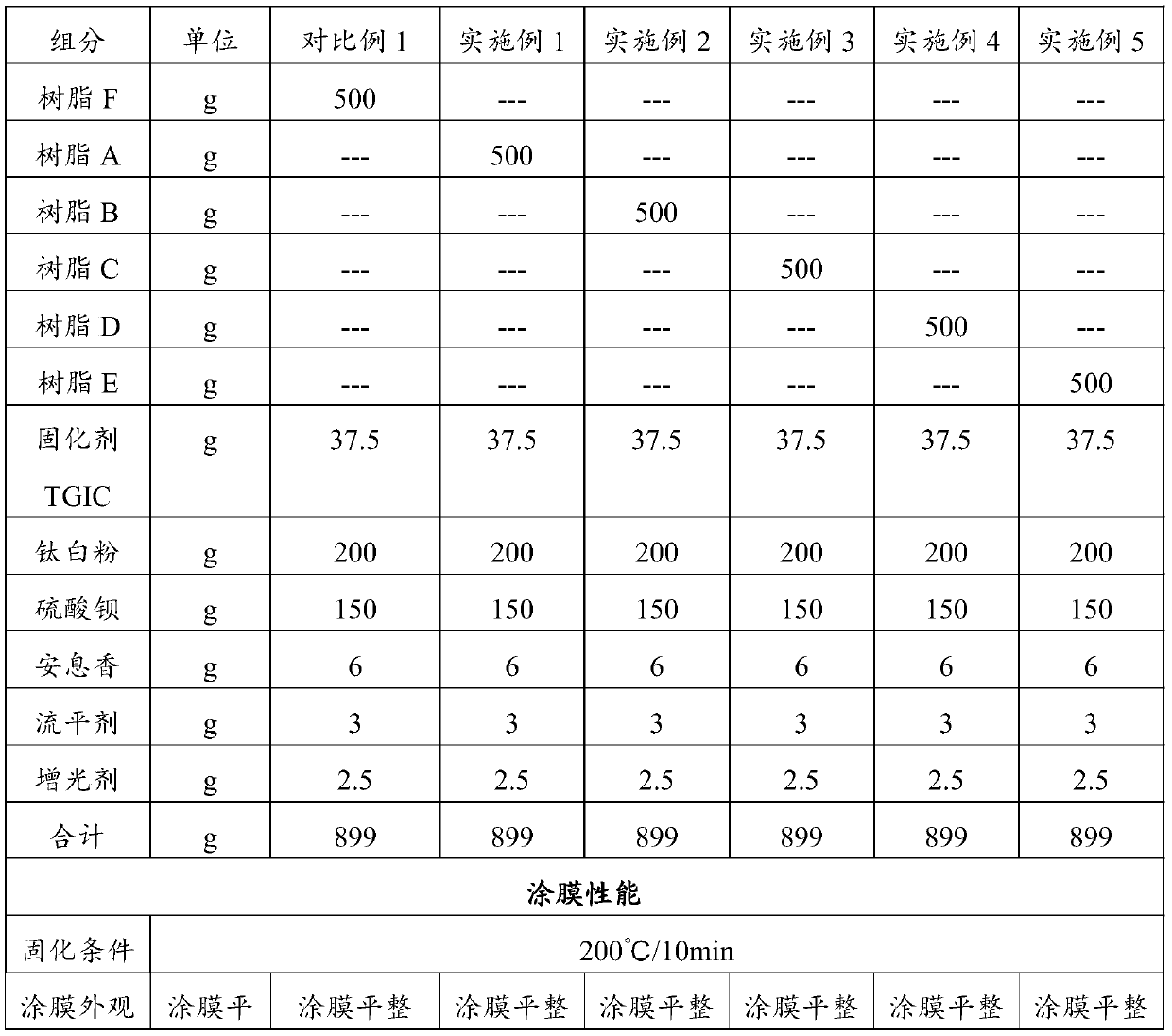

Examples

Embodiment 1

[0045] This embodiment is the preparation of polyester resin for powder coating

[0046] The raw materials of polyester resin for powder coatings are: polyols, polyacids, acidolysis agents, esterification catalysts, antioxidants and curing accelerators, among which polyols include neopentyl glycol, bisphenol A, bisphenol S and trihydroxy Methyl propane; polybasic acid is terephthalic acid and adipic acid; polybasic acid is terephthalic acid and adipic acid; esterification catalyst is monobutyltin oxide; acidolysis agent is isophthalic acid and 1,4-cyclo Hexane dicarboxylic acid, and the molar ratio is 2:1; Antioxidant is antioxidant 1076 and antioxidant 168, and mass ratio is 1:1; Curing accelerator is triphenyl ethyl phosphorus bromide; Wherein, polyhydric alcohol and polyhydric The molar ratio of acid is 1.1:1, the ratio of the total molar weight of polybasic acid and acidolysis agent to the molar weight of polyol is 1.0476:1, and the amount of bisphenol A and bisphenol S ac...

Embodiment 2

[0049] This embodiment is the preparation of polyester resin for powder coating

[0050] The raw materials of polyester resin for powder coatings are: polyols, polyacids, acidolysis agents, esterification catalysts, antioxidants and curing accelerators, wherein polyols include neopentyl glycol, bisphenol A and trimethylolpropane; The polybasic acid is terephthalic acid and adipic acid; the polybasic acid is terephthalic acid and adipic acid; the esterification catalyst is monobutyltin oxide; the acidolysis agent is isophthalic acid and 1,4-cyclohexanedicarboxylic acid , and the molar ratio is 2:1; the antioxidant is antioxidant 1076 and antioxidant 168, and the mass ratio is 2:1; the curing accelerator is triphenylethylphosphorus bromide; wherein, the molar ratio of polyhydric alcohol / polyacid is 1.13:1, the ratio of the total molar mass of polybasic acid and acidolytic agent to the molar mass of polyol is 1.0502:1, the amount of bisphenol A accounts for 7wt% of the total mass...

Embodiment 3

[0053] This embodiment is the preparation of polyester resin for powder coating

[0054] The raw materials of polyester resin for powder coatings are: polyols, polyacids, acidolysis agents, esterification catalysts, antioxidants and curing accelerators, wherein polyols include neopentyl glycol, bisphenol A and trimethylolpropane; The polybasic acid is terephthalic acid and adipic acid; the polybasic acid is terephthalic acid and adipic acid; the esterification catalyst is monobutyltin oxide; the acidolysis agent is isophthalic acid and 1,4-cyclohexanedicarboxylic acid , and the molar ratio is 2:1; the antioxidant is antioxidant 1010 and antioxidant 168, and the mass ratio is 2:1; the curing accelerator is triphenylethylphosphorus bromide; wherein, the molar ratio of polyhydric alcohol / polyacid is 1.15, the ratio of the total molar weight of polybasic acid and acidolytic agent to the molar weight of polyol is 1.0475:1, the consumption of bisphenol A accounts for 10wt% of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com