High-strength low temperature-resistant glass reinforced plastic and preparation method thereof

A technology of FRP and low temperature resistance, which is applied in the field of high-strength and low-temperature-resistant FRP and its preparation. It can solve the problems affecting the scope and service life of FRP, insufficient strength of FRP, and low-temperature embrittlement, so as to prevent low-temperature embrittlement, increase strength and Mechanical properties, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

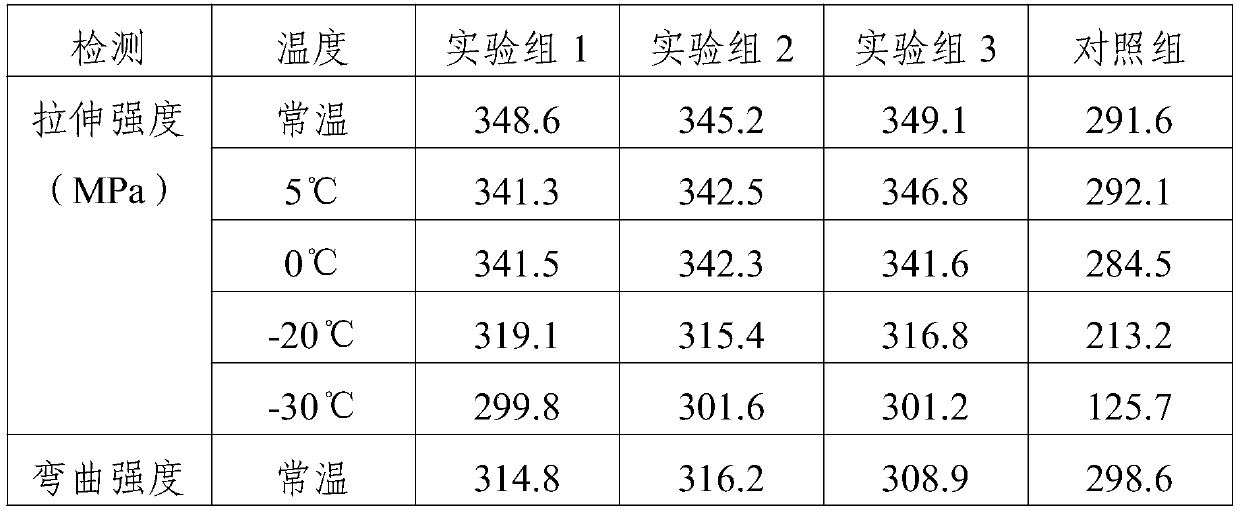

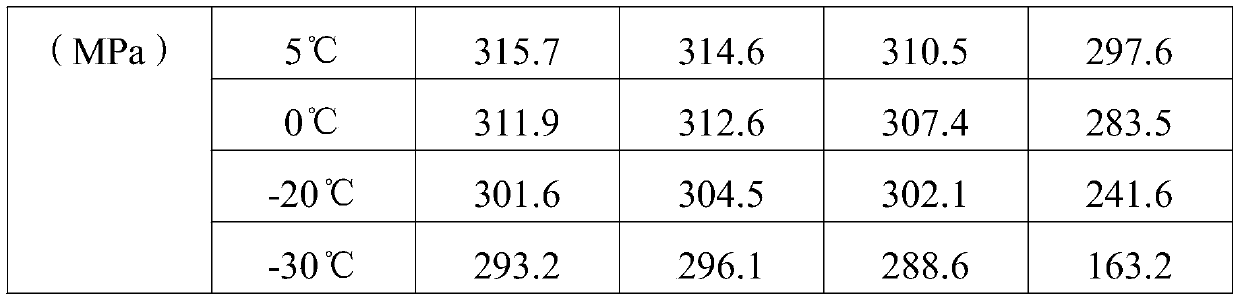

Examples

Embodiment 1

[0028] A high-strength and low-temperature-resistant FRP composite material is made of the following raw materials by weight: 14 parts of glass fiber, 12 parts of unsaturated polyester resin, 8 parts of acetal resin, and 12 parts of epoxy resin , 4 parts of carbon fiber, 2 parts of kaolin, 1 part of diatomaceous earth, 2 parts of dioctyl maleate, 1 part of molybdenum dioxide, 2 parts of zinc oxide, 1 part of nano titanium dioxide, 2 parts of copovidone, hexamethyl 1 part of phosphoric acid triamide, 1 part of diisobutyl nylon acid, 2 parts of sodium polyacrylate, 1 part of crosslinking agent, 2 parts of lubricant, and 1 part of antioxidant.

[0029] The crosslinking agent is a mixture of dicumyl hydrogen peroxide, diethylenetriamine, and vinyltributanone oximosilane in a mass ratio of 4:2:1; the lubricant is microcrystalline paraffin, stearin Any one in butyl acid, polyethylene wax; Described antioxidant is p-phenylenediamine, dihydroquinoline, bis(3,5-tertiary butyl-4-hydroxy...

Embodiment 2

[0039] A high-strength and low-temperature-resistant FRP composite material is made of the following raw materials by weight: 15 parts of glass fiber, 14 parts of unsaturated polyester resin, 10 parts of acetal resin, and 14 parts of epoxy resin , 6 parts of carbon fiber, 4 parts of kaolin, 3 parts of diatomaceous earth, 3 parts of dioctyl maleate, 2 parts of molybdenum dioxide, 3 parts of zinc oxide, 3 parts of nano titanium dioxide, 3 parts of copovidone, hexamethyl 3 parts of phosphoric acid triamide, 2 parts of diisobutyl nylon acid, 3 parts of sodium polyacrylate, 3 parts of crosslinking agent, 2.4 parts of lubricant, and 2 parts of antioxidant.

[0040] The crosslinking agent is a mixture of dicumyl hydrogen peroxide, diethylenetriamine, and vinyltributanone oximosilane in a mass ratio of 4:2:1; the lubricant is microcrystalline paraffin, stearin Any one in butyl acid, polyethylene wax; Described antioxidant is p-phenylenediamine, dihydroquinoline, bis(3,5-tertiary butyl...

Embodiment 3

[0050] A high-strength and low-temperature-resistant FRP composite material is made of the following raw materials by weight: 14.5 parts of glass fiber, 13 parts of unsaturated polyester resin, 9 parts of acetal resin, and 13 parts of epoxy resin , 5 parts of carbon fiber, 3 parts of kaolin, 2 parts of diatomaceous earth, 2.5 parts of dioctyl maleate, 1.5 parts of molybdenum dioxide, 2.5 parts of zinc oxide, 2 parts of nano-titanium dioxide, 2.5 parts of copovidone, hexamethyl 2 parts of phosphoric acid triamide, 1.5 parts of diisobutyl nylon acid, 2.5 parts of sodium polyacrylate, 2 parts of crosslinking agent, 2.2 parts of lubricant, and 1.5 parts of antioxidant.

[0051] The crosslinking agent is a mixture of dicumyl hydrogen peroxide, diethylenetriamine, and vinyltributanone oximosilane in a mass ratio of 4:2:1; the lubricant is microcrystalline paraffin, stearin Any one in butyl acid, polyethylene wax; Described antioxidant is p-phenylenediamine, dihydroquinoline, bis(3,5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com