Device and method for heterotrophic production of microalgae by chicken manure degradation liquid

A technology for producing microalgae and degradation liquid, which is applied in the field of agriculture and breeding, and can solve problems such as unstable production, immature technology, and low utilization rate of chicken manure nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

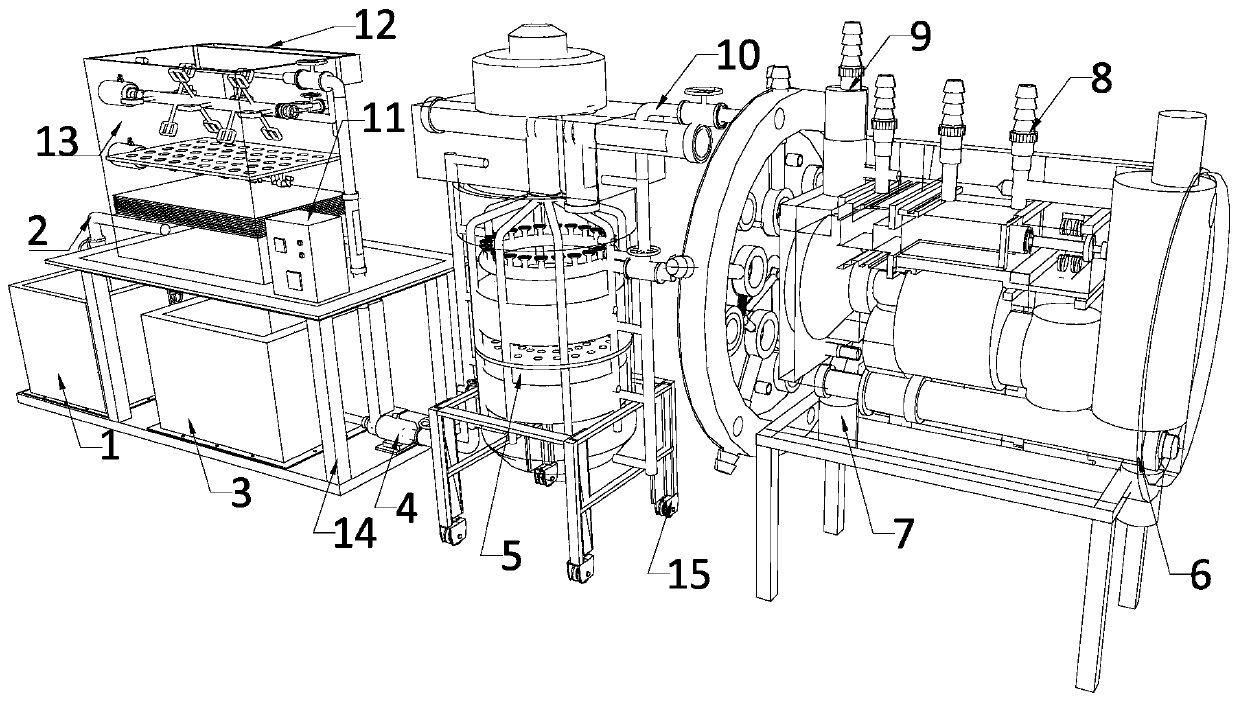

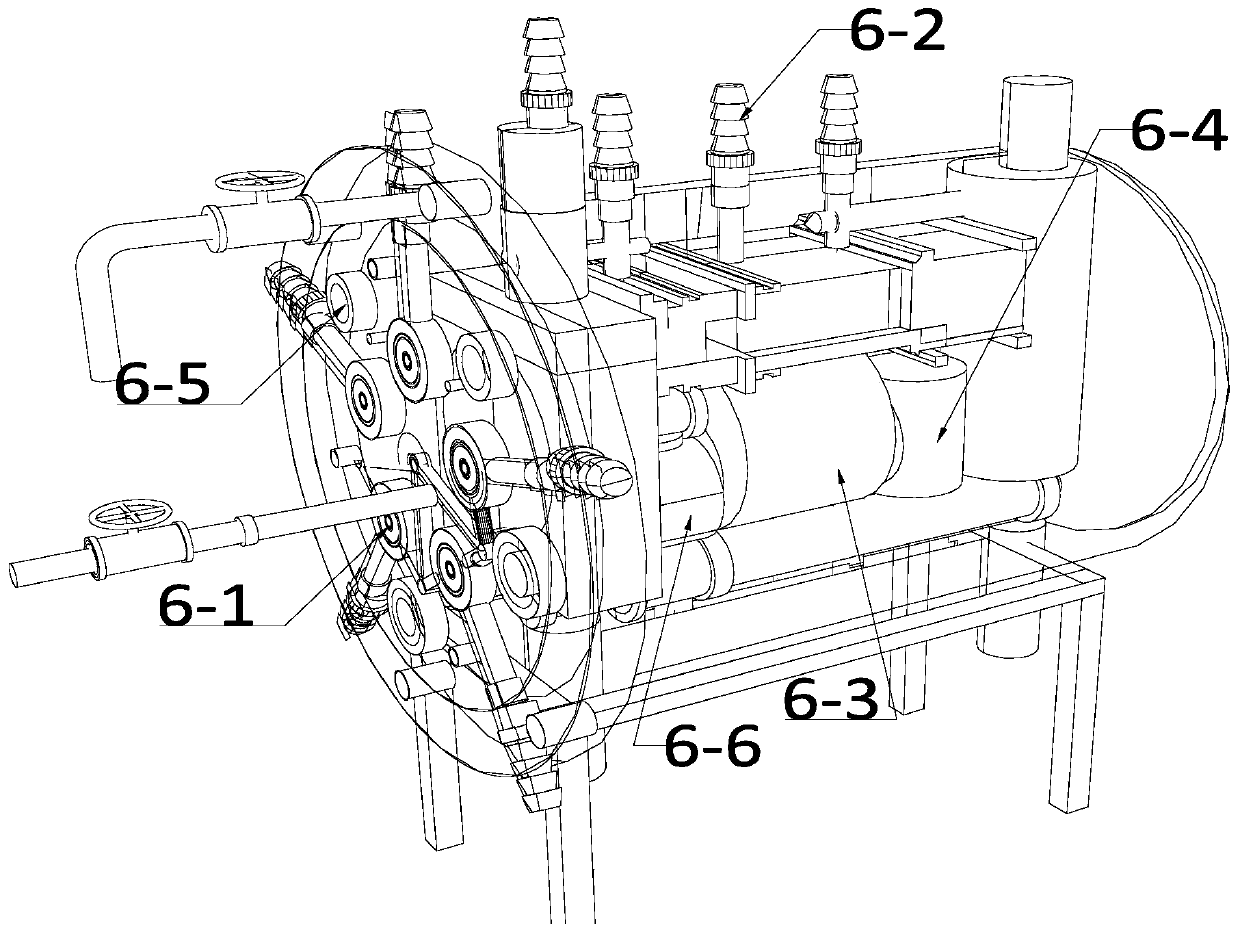

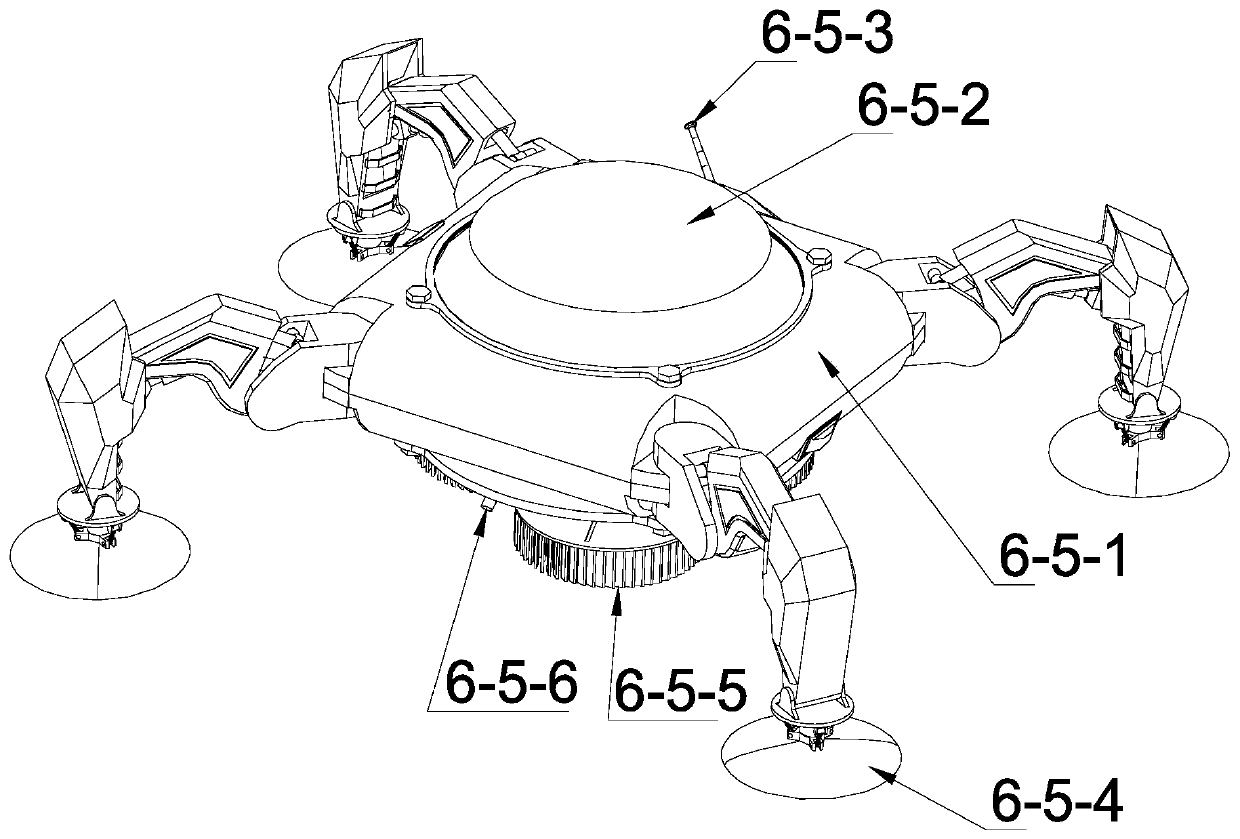

Method used

Image

Examples

Embodiment 1

[0050] Manufacture distillation column 5 shell of the present invention according to the following steps, and by mass percentage:

[0051] Step 1: Add 0.1% of methyl tert-butyl ether in the proportioning components into the vertical reactor according to the mass percentage, and add 0.2% of medical pure water at the same time, start the mixer in the vertical reactor, and set the speed at 0.8 rpm;

[0052] Step 2: After running the vertical reactor for 0.8 minutes, add 2.3% coagulant admixture and 4,4'-(1-methylethylene)bis(2,6-dibromophenol) and di-2 - polymer 0.4% of (chloromethyl) epoxy ethyl acrylate, start the steam soda water heater in the vertical reactor, make the temperature rise to 2.8 ℃, add accelerator 1.5% and iron nanoparticles 0.6%, in Stir evenly in the vertical reaction kettle to obtain the Y component homogenate;

[0053] Step 3: Weigh 2.7% of the TPS modified catalyst in the proportioning component according to the mass percentage, mix and stir with the Y co...

Embodiment 2

[0055] Manufacture distillation column 5 shell of the present invention according to the following steps, and by mass percentage:

[0056] Step 1: Add 35% of methyl tert-butyl ether in the proportioning components into the vertical reactor according to the mass percentage, and add 65% of medical pure water at the same time, start the mixer in the vertical reactor, and set the speed at 35rpm;

[0057]Step 2: After running the vertical reactor for 65 minutes, add 20% coagulant admixture and 4,4'-(1-methylethylene)bis(2,6-dibromophenol) and di-2 - Polymer 48% of (chloromethyl) oxyethylene acrylate, start the steam soda water heater in the vertical reactor, make the temperature rise to 20°C, add accelerator 48% and iron nanoparticles 96%, in Stir evenly in the vertical reaction kettle to obtain the Y component homogenate;

[0058] Step 3: Weigh 47% of the TPS modified catalyst in the proportioning component according to the mass percentage, mix and stir with the Y component homo...

Embodiment 3

[0062] The use effect of the shell of the distillation tower 5 prepared in Examples 1-2 and the same parts obtained in the comparative example were compared. The heat distortion temperature, anti-torsion strength, 10KN compression deformation rate and oil erosion rate of the two are counted, and the results are shown in Table 1.

[0063]

[0064] As can be seen from Table 1, the above-mentioned performance indexes of the shell of the distillation tower 5 according to the present invention are better than those produced by the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com