Anode and its preparation method and application, ozone generating system and tooth cleaning device

An anode and ozone technology, applied in chemical instruments and methods, electrodes, devices for cleaning dental cavities, etc., can solve problems such as inability to maintain bactericidal effect and difficult generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing the above-mentioned anode according to an embodiment, the method includes the following steps:

[0029] S1: Pretreating the titanium substrate to obtain a pretreated titanium substrate.

[0030] Wherein, the pretreatment may include sandblasting. The roughness of the surface of the titanium substrate can be increased by sandblasting, which is beneficial to improving the adhesion of the composite oxide layer on the surface of the titanium substrate. The blasting material used in the blasting treatment may be corundum or quartz sand, for example.

[0031] S2: Etching the pretreated titanium substrate in an etching solution to obtain an etched titanium substrate.

[0032] Wherein, the etching solution may be selected from at least one of oxalic acid solution and hydrochloric acid solution. Further, the concentration of the oxalic acid solution may be 20% to 50% by weight, and the concentration of the hydrochloric acid solution may be 10% to 30% ...

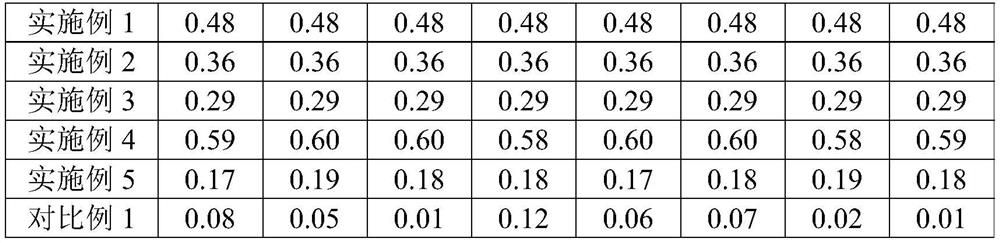

Embodiment 1

[0046] The titanium plate was sandblasted, then etched in an oxalic acid solution with a concentration of 20% by weight at 80° C. for 30 min, and then cleaned with pure water. Dissolve tin chloride, ruthenium chloride, manganese chloride, butyl titanate and nickel chloride in ethanol to obtain a mixed solution, wherein, Sn:Ru:Mn:Ti:Ni (molar ratio)=320:12: 1:4:10, the weight ratio of the total weight of tin chloride, ruthenium chloride, manganese chloride, butyl titanate and nickel chloride to ethanol is 1:5. The mixed solution was coated on the surface of the titanium plate, dried at 120°C for 10min, and then fired at 450°C for 1h. Repeat coating, drying and firing under the above conditions for 4 times, the last firing temperature was increased to 600° C. and fired for 3 hours to obtain the anode prepared in this example.

Embodiment 2

[0048] The preparation steps of the anode in this embodiment are roughly the same as those in Embodiment 1, except that in the mixed liquid, Sn:Ru:Mn:Ti:Ni (molar ratio)=400:15:1:5:12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com