Preparation method and application of Cu-MOF/BiVO4 composite photoelectrode

A composite photoelectrode technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of limitation, easy recombination of photogenerated electrons and holes, etc., to achieve enhanced capture ability, cheap and non-toxic materials, good chemical The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A Cu-MOF / BiVO 4 The preparation method of composite photoelectrode comprises steps as follows:

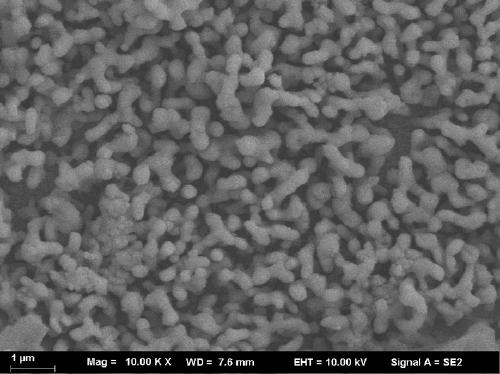

[0028] A. BiVO with worm-like structure prepared on FTO substrate 4

[0029] The BiVO with worm-like structure prepared on the FTO substrate 4 The steps are:

[0030] (1) First, prepare solution A as 0.4M KI solution and 0.04M Bi(NO 3 ) 3 The mixed liquid of the solution is 50ml in total, adjust the pH to 1.7 with concentrated nitric acid (3 drops of concentrated nitric acid), the B solution is 20ml of 0.23M ethanol solution of p-benzoquinone, and the AB solution is mixed evenly;

[0031] (2) Then use the mixed solution as the electrolyte, use the constant voltage electrochemical deposition method to conduct electrodeposition on the FTO substrate, and electrodeposit for 5 minutes under the applied bias voltage -0.1V (relative to Ag / AgCl), and then obtain the BiOI photoelectrode ;

[0032] (3) Prepare 10ml of 0.2M dimethyl sulfoxide (DMSO) solution of vanadyl acetylace...

Embodiment 2

[0042] A Cu-MOF / BiVO 4 The preparation method of composite photoelectrode comprises steps as follows:

[0043] A. BiVO with worm-like structure prepared on FTO substrate 4

[0044] The BiVO with worm-like structure prepared on the FTO substrate 4 The steps are:

[0045] (1) First, prepare solution A as 0.4M KI solution and 0.04M Bi(NO 3 ) 3 The mixed liquid of the solution is 50ml in total, adjust the pH to 1.7 with concentrated nitric acid (3 drops of concentrated nitric acid), the B solution is 20ml of 0.23M ethanol solution of p-benzoquinone, and the AB solution is mixed evenly;

[0046] (2) Then use the mixed solution as the electrolyte, use the constant voltage electrochemical deposition method to conduct electrodeposition on the FTO substrate, and electrodeposit for 5 minutes under the applied bias voltage -0.1V (relative to Ag / AgCl), and then obtain the BiOI photoelectrode ;

[0047] (3) Prepare 10ml of 0.2M dimethyl sulfoxide (DMSO) solution of vanadyl acetylace...

Embodiment 3

[0053] A Cu-MOF / BiVO 4 The preparation method of composite photoelectrode comprises steps as follows:

[0054] A. BiVO with worm-like structure prepared on FTO substrate 4

[0055] The BiVO with worm-like structure prepared on the FTO substrate 4 The steps are:

[0056] (1) First, prepare solution A as 0.4M KI solution and 0.04M Bi(NO 3 ) 3 The mixed liquid of the solution is 50ml in total, adjust the pH to 1.7 with concentrated nitric acid (3 drops of concentrated nitric acid), the B solution is 20ml of 0.23M ethanol solution of p-benzoquinone, and the AB solution is mixed evenly;

[0057] (2) Then use the mixed solution in step (1) as the electrolyte, and use the constant voltage electrochemical deposition method to conduct electrodeposition on the FTO substrate, and electrodeposit for 5 minutes under the applied bias voltage -0.1V (relative to Ag / AgCl), That is, the BiOI photoelectrode is obtained;

[0058] (3) Prepare 10ml of 0.2M dimethyl sulfoxide (DMSO) solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com