Modified graphene oxide/cobalt-based composite coating and preparation method and application thereof

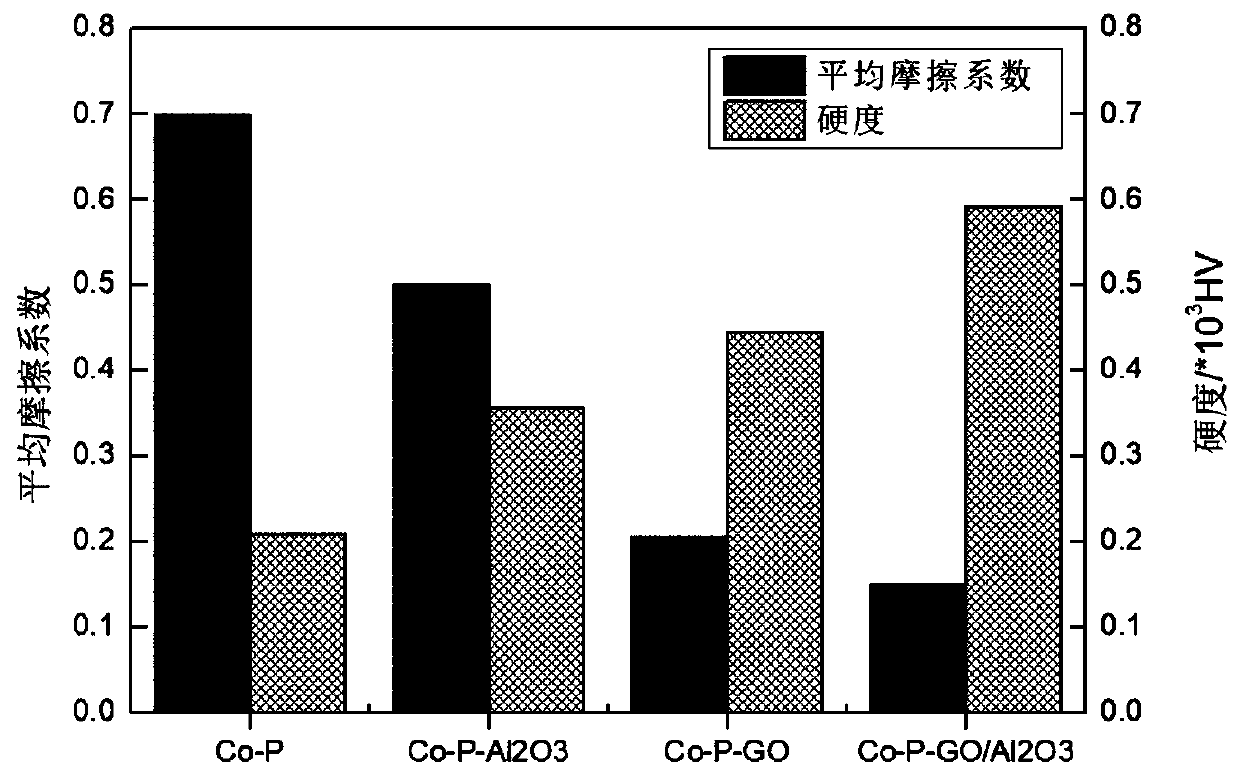

A technology of composite coating and oxide stone, applied in the direction of coating, electrolytic coating, etc., can solve the problems of curling and wrinkles, poor stability of two-dimensional structure, and agglomeration of dispersion system, so as to reduce the friction coefficient and wear rate, not easy to agglomerate, Effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

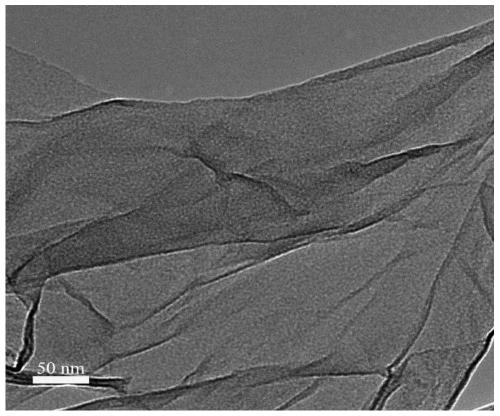

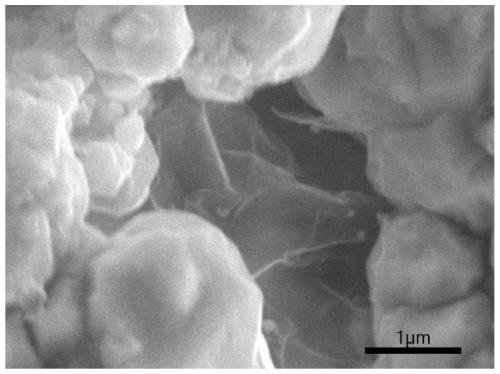

[0033] 1. Modified graphene oxide: Mix 1g / L alumina and 0.1g / L 3-aminopropyltriethoxysilane in absolute ethanol, stir at 200rpm for 60min, then filter and dry to obtain amino Aluminum oxide powder, graphene oxide powder and aminated aluminum oxide powder were added to deionized water, 50W ultrasonic vibration for 60min to disperse, and then stirred at 300rpm for 30min to obtain modified graphene.

[0034] 2. Dissolve cobalt sulfate, sodium phosphate, boric acid, sodium gluconate, cetyltrimethylammonium bromide, and modified graphene oxide into deionized water, and configure a composite electroplating solution; wherein, the concentration of cobalt sulfate is 50g / L, the concentration of sodium phosphate is 80g / L, the concentration of boric acid is 60g / L, the concentration of sodium gluconate is 40g / L, the concentration of cetyltrimethylammonium bromide is 1g / L, and modified graphite oxide Alkene 0.1g / L, adjust the pH value of the electroplating solution to 3 with sodium hydroxi...

Embodiment 2

[0037] 1. Modified graphene oxide: Mix 2g / L alumina and 0.2g / L 3-aminopropyltriethoxysilane in alcohol, stir at 300rpm for 60min and filter to obtain aminated alumina. Graphene oxide powder and aminated alumina powder were added into deionized water, dispersed by 80W ultrasonic vibration for 60min, and then stirred at 300rpm for 60min to obtain modified graphene oxide.

[0038] 2. Dissolve cobalt sulfate, sodium hypophosphite, boric acid, sodium citrate, sodium lauryl sulfate, and modified graphene oxide into deionized water to make a composite electroplating solution; wherein, the concentration of cobalt sulfate is 100g / L , The concentration of sodium hypophosphite is 20g / L, the concentration of boric acid is 20g / L, the concentration of sodium citrate is 40g / L, the concentration of sodium lauryl sulfate is 1g / L, and the concentration of modified graphene oxide is 0.1g / L , adjust the pH of the plating solution to 3 with sodium hydroxide and dilute sulfuric acid.

[0039] 3. T...

Embodiment 3

[0048] 1. Modified graphene oxide: Mix 1g / L alumina and 0.1g / L 3-aminopropyltriethoxysilane in alcohol, stir at 600rpm for 60min and filter to obtain aminated alumina. Graphene oxide powder and aminated alumina powder were added into deionized water, dispersed by 80W ultrasonic vibration for 30min, and then stirred at 600rpm for 30min to obtain modified graphene.

[0049] 2. Dissolve cobalt sulfate, sodium phosphate, boric acid, ammonium citrate, sodium lauryl sulfate, and modified graphene oxide into deionized water to make a composite electroplating solution; wherein the concentration of cobalt sulfate is 150g / L, The concentration of sodium phosphate is 80g / L, the concentration of boric acid is 40g / L, the concentration of ammonium citrate is 40g / L, the concentration of sodium lauryl sulfate is 0.1g / L, and the concentration of modified graphene oxide is 0.5g / L. Adjust the pH of the plating solution to 4 with sodium hydroxide and dilute sulfuric acid.

[0050] 3. Take the ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com