Preparation method and application of silicon carbide ceramic-based nano-composite material

A nanocomposite, silicon carbide ceramic-based technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as hindering practical application, volume expansion, poor conductivity, etc., to promote diffusion. and electron transfer, enhance conductivity, and achieve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

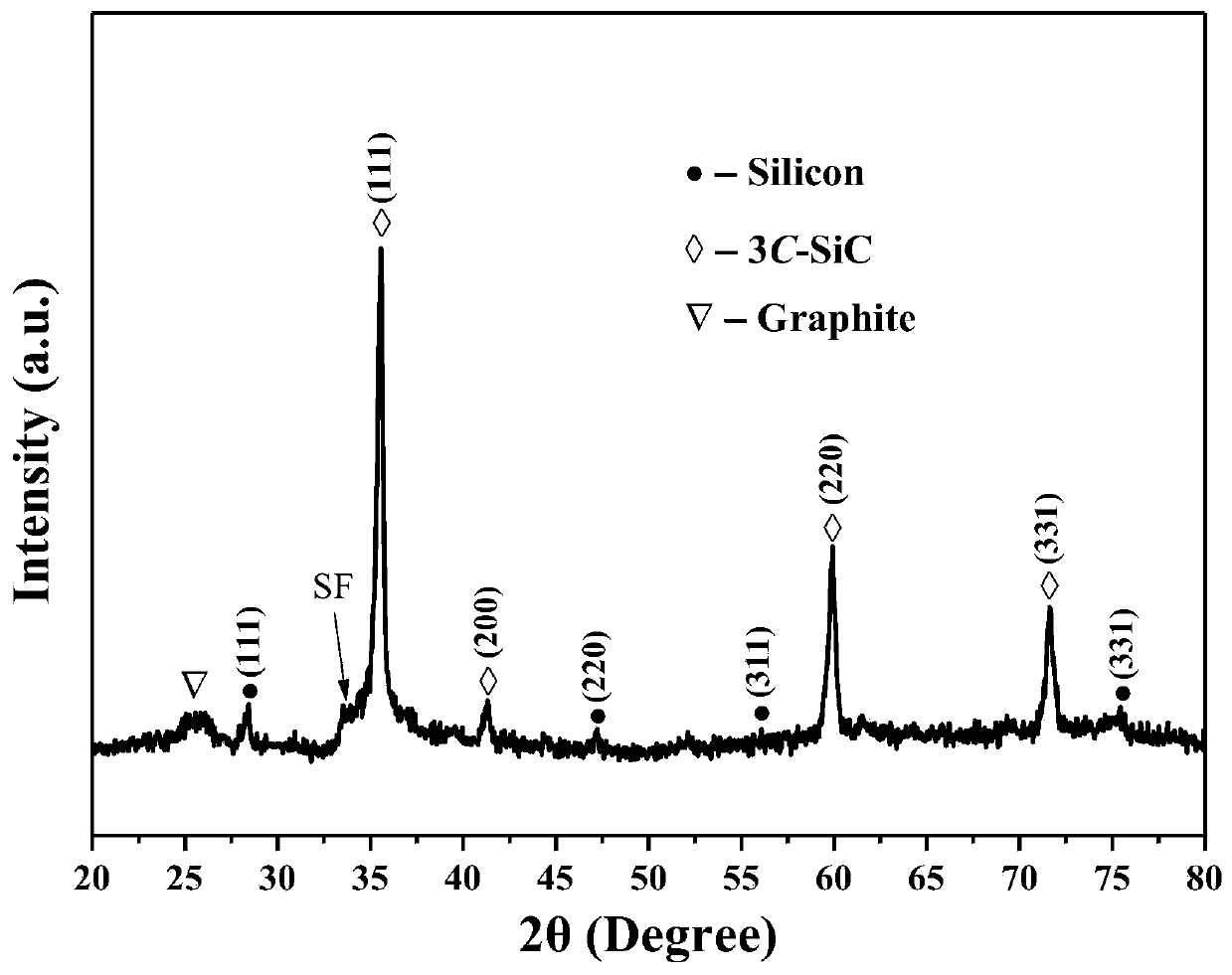

[0026] Take the industrial silicon block and place it on the copper base as the anode, and the graphite rod as the cathode, and adjust the distance between the two electrodes to 30mm. Vacuum the reaction chamber to about 10 -2 Pa, filled with argon and hydrogen at a ratio of 2:1 to reach 2×10 4 Pa and 1×10 4 Pa, then filled with 0.25×10 4 Pa methane gas, turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the poles and stabilize the arc, evaporate the bulk silicon target material into silicon atoms, react with the carbon atoms decomposed from methane gas, nucleate and grow and gather The nano-powder is deposited on the wall of the reaction chamber, and the powder is collected through a passivation process to obtain a silicon carbide ceramic matrix nano-composite material.

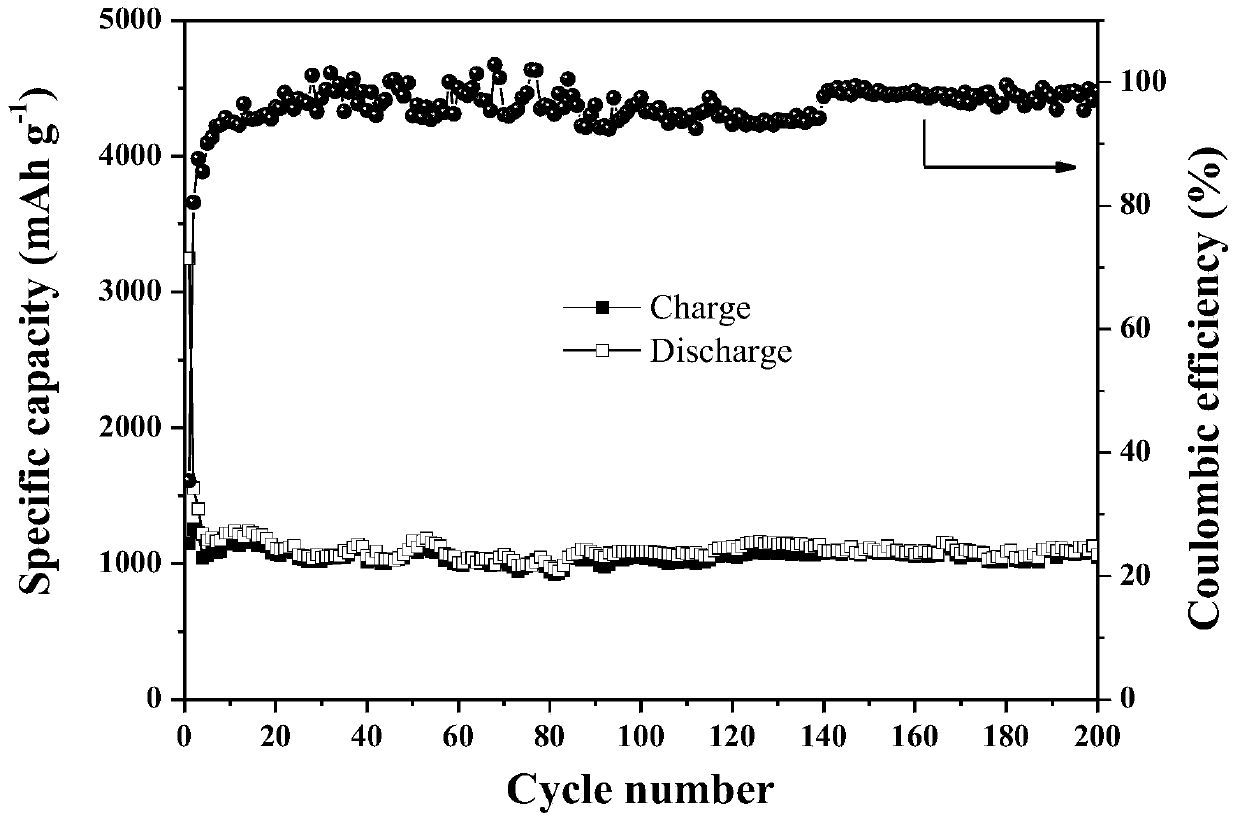

[0027] The prepared silicon carbide ceramic-based nanocomposite material was used as an active material, mixed with a conductive agent and a...

Embodiment 2

[0029] Take the industrial silicon block and place it on the copper base as the anode, and the graphite rod as the cathode, and adjust the distance between the two electrodes to 30mm. Vacuum the reaction chamber to about 10 -2 Pa, filled with argon and hydrogen at a ratio of 2:1 to reach 2×10 4 Pa and 1×10 4 Pa, then filled with 0.5×10 4 Pa methane gas, turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the poles and stabilize the arc, evaporate the bulk silicon target material into silicon atoms, react with the carbon atoms decomposed from methane gas, nucleate and grow and gather The nano-powder is deposited on the wall of the reaction chamber, and the powder is collected through a passivation process to obtain a silicon carbide ceramic matrix nano-composite material.

[0030] The prepared silicon carbide ceramic-based nanocomposite material was used as an active material, mixed with a conductive agent and a ...

Embodiment 3

[0032] Take the industrial silicon block and place it on the copper base as the anode, and the graphite rod as the cathode, and adjust the distance between the two electrodes to 30mm. Vacuum the reaction chamber to about 10 -2 Pa, filled with argon and hydrogen at a ratio of 2:1 to reach 2×10 4 Pa and 1×10 4 Pa, then filled with 1×10 4 Pa methane gas, turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the poles and stabilize the arc, evaporate the bulk silicon target material into silicon atoms, react with the carbon atoms decomposed from methane gas, nucleate and grow and gather The nano-powder is deposited on the wall of the reaction chamber, and the powder is collected through a passivation process to obtain a silicon carbide ceramic matrix nano-composite material.

[0033] The prepared silicon carbide ceramic-based nanocomposite material was used as an active material, mixed with a conductive agent and a bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com