Cobalt-aluminum composite oxide catalyst and preparation method and application thereof

An aluminum composite and catalyst technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of low catalytic activity of catalyst, achieve improved catalytic activity, The effect of improving convective mass transfer efficiency and catalytic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of cobalt-aluminum composite oxide catalyst, comprising the steps of:

[0045] (1) Preparation of metal ion precursor solution: weigh 10.91g Co(NO 3 ) 2 ·6H 2 O and 4.69gAl(NO 3 ) 3 9H 2 O was dissolved in a mixed solution of 50 mL of water and ethanol (volume ratio of 1:1) to obtain a mixed solution with a total metal ion concentration of 1 mol / L (Co / Al=3);

[0046] (2) Catalyst preparation: Slowly add polystyrene nano-microspheres to the above mixed solution, let it stand for 6 hours, then filter the remaining solution with suction, dry the obtained solid in an oven at 80°C for 12 hours, and then place it Put it into a muffle furnace for calcination, the heating rate is 1°C / min, and keep at 500°C for 2 hours to obtain a cobalt-aluminum composite oxide catalyst.

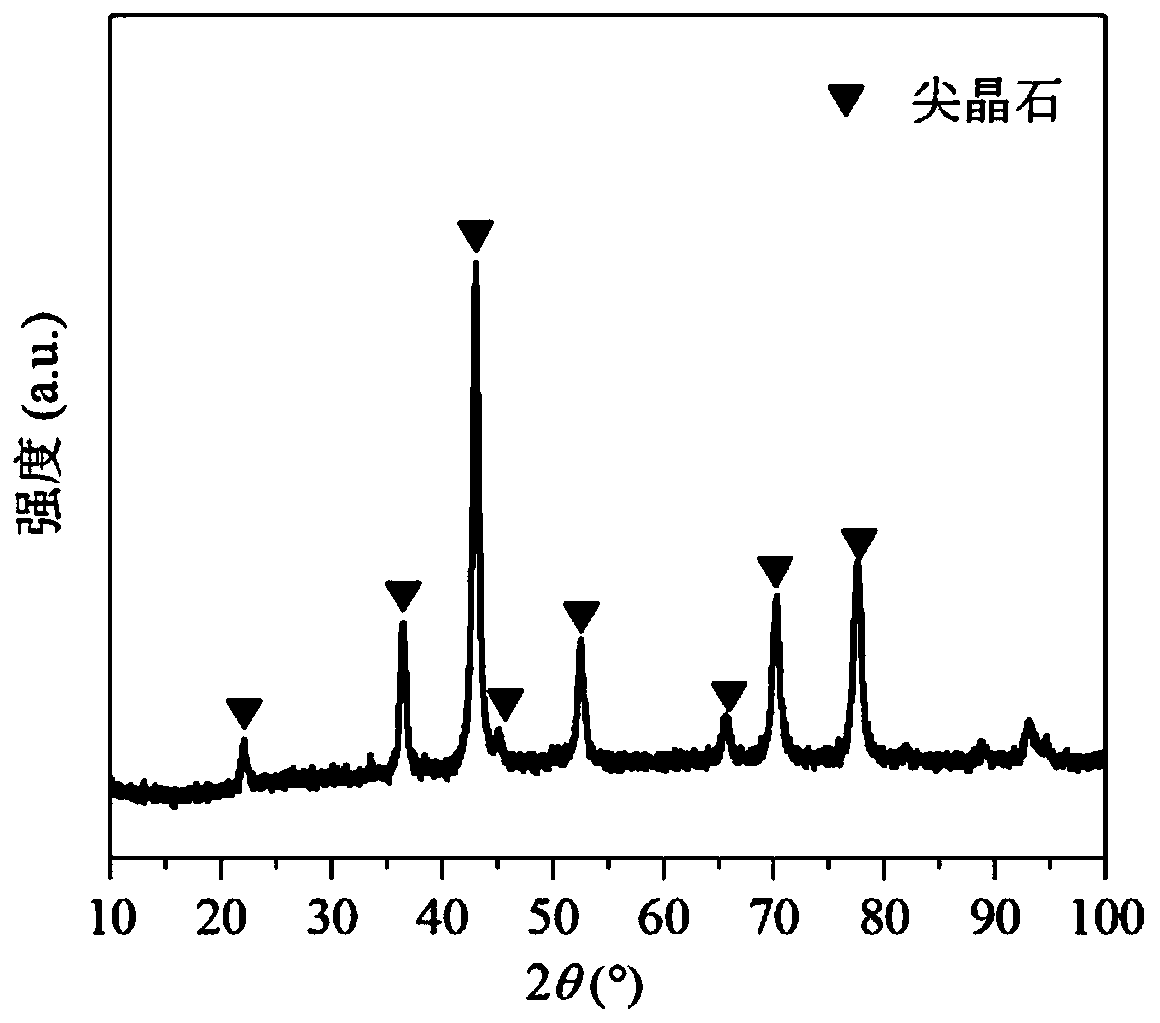

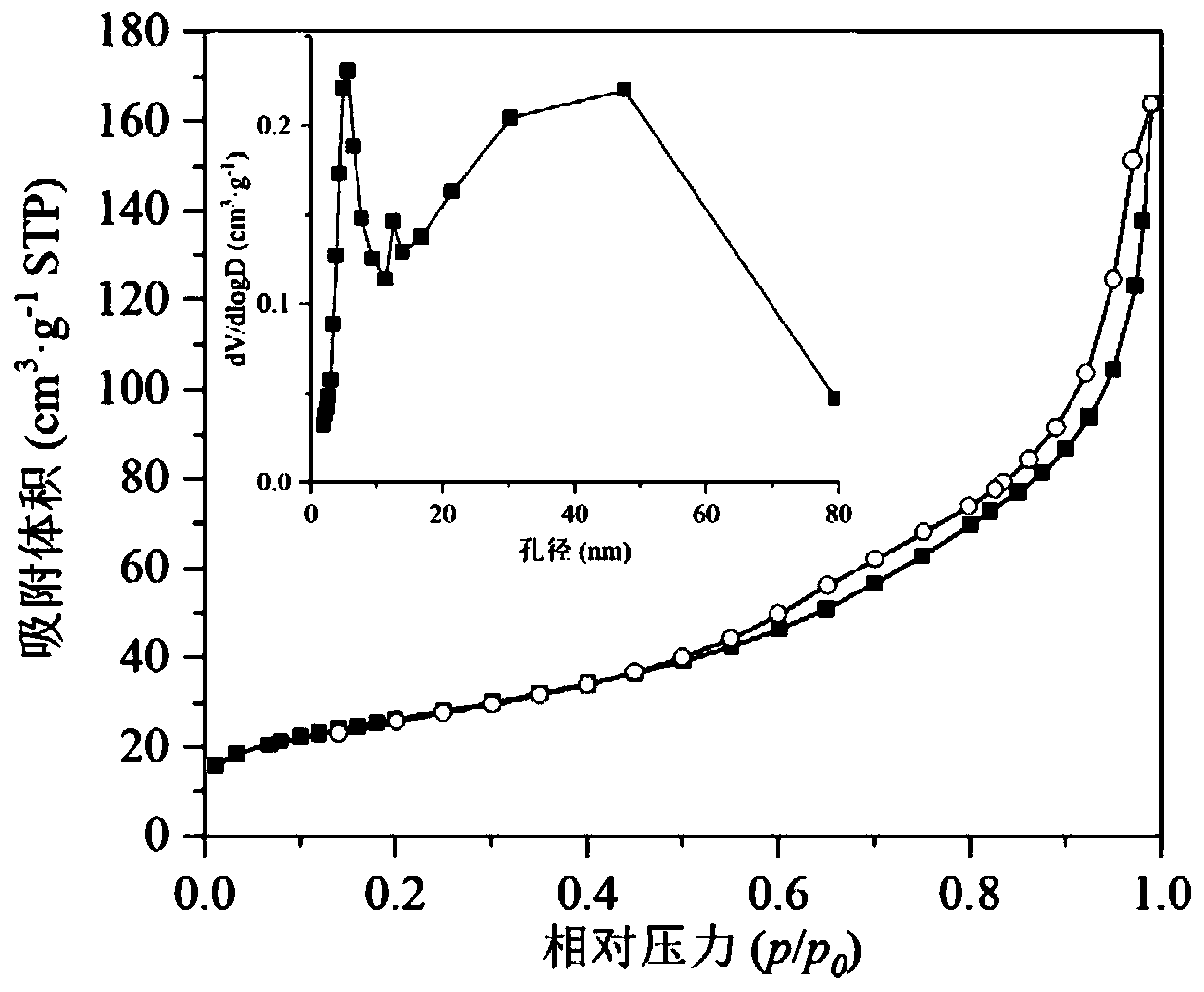

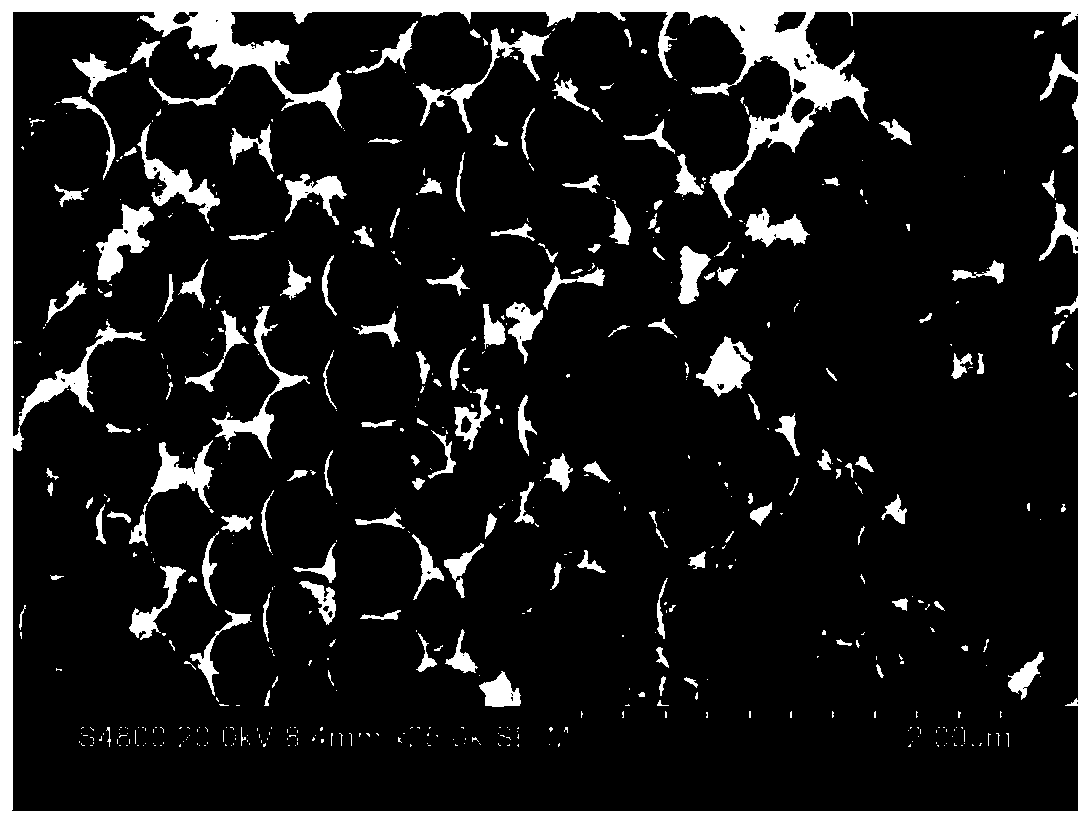

[0047] Carry out crystal phase test to above-mentioned catalyst with X-ray powder diffractometer, the result is as follows figure 1 shown by figure 1 It can be seen that the main ...

Embodiment 2

[0052] A preparation method of cobalt-aluminum composite oxide catalyst, comprising the steps of:

[0053] (1) Preparation of metal ion precursor solution: weigh 7.28g Co(NO 3 ) 2 ·6H 2 O and 9.38gAl(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of 50mL water and ethanol (volume ratio is 1:1), obtains the mixed solution (Co / Al=1) that total metal ion concentration is 1mol / L;

[0054] (2) Catalyst preparation: Slowly add polystyrene nano-microspheres to the above mixed solution, let it stand for 6 hours, then filter the remaining solution with suction, dry the obtained solid in an oven at 80°C for 12 hours, and then place it Put it into a muffle furnace for calcination, the heating rate is 1°C / min, and keep at 500°C for 2 hours to obtain a cobalt-aluminum composite oxide catalyst.

[0055] The crystal phase of the catalyst was tested with an X-ray powder diffractometer, and the results showed that the main phase of the catalyst was spinel, and the average grain size ...

Embodiment 3

[0060] A preparation method of cobalt-aluminum composite oxide catalyst, comprising the steps of:

[0061] (1) Preparation of metal ion precursor solution: weigh 4.85g Co(NO 3 ) 2 ·6H 2 O and 12.50gAl(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of 50mL water and ethanol (volume ratio is 1:1), obtains the mixed solution (Co / Al=0.5) that total metal ion concentration is 1mol / L;

[0062] (2) Catalyst preparation: Slowly add polystyrene nano-microspheres to the above mixed solution, let it stand for 6 hours, then filter the remaining solution with suction, dry the obtained solid in an oven at 80°C for 12 hours, and then place it Put it into a muffle furnace for calcination, the heating rate is 1°C / min, and keep at 500°C for 2 hours to obtain a cobalt-aluminum composite oxide catalyst.

[0063] The crystal phase of the catalyst was tested with an X-ray powder diffractometer, and the results showed that the main phase of the catalyst was spinel, and the average grain si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com