Network structure nanometer zinc oxide preparation method

A technology of nano-zinc oxide and network structure, applied in the nano field, can solve the problems of nano-zinc oxide structure, size and uniformity difference, large difference in nano-network structure morphology, influence of nano-zinc oxide performance, etc. The effect of easy control of conditions, small difference in morphology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

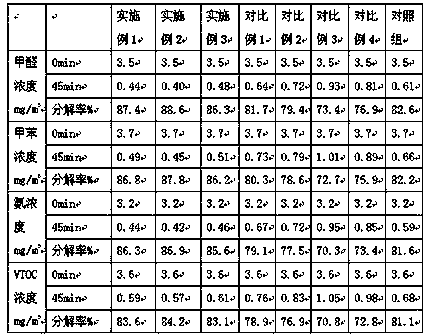

Examples

Embodiment 1

[0019] A preparation method of network structure nano-zinc oxide, the specific preparation method is as follows:

[0020] 1) Add antimony potassium tartrate into deionized water, stir at a speed of 130r / min for 15min, make it fully dissolved, add polyvinylpyrrolidone, continue stirring for 20min, after it dissolves, add thioacetamide into the mixed solution , continue to stir for 35min to obtain ladder potassium tartrate / PVP / TAA mixture solution;

[0021] 2) Put the cellulose microfibril suspension in a large beaker with ice cubes, treat it under 150W ultrasonic wave for 50s, let it stand at room temperature for 10min after the treatment, and then titrate the cellulose microfiber suspension to chlorine with a glass syringe. In the calcium chloride solution, soak the obtained spherical cellulose wet gel in tert-butanol solution for solvent replacement, and vacuum freeze-dry after the replacement is complete, to obtain spherical cellulose aerogel;

[0022] 3) Put zinc sulfate h...

Embodiment 2

[0029] A preparation method of network structure nano-zinc oxide, the specific preparation method is as follows:

[0030] 1) Add antimony potassium tartrate into deionized water, stir at a speed of 150r / min for 13min, make it fully dissolved, add polyvinylpyrrolidone, continue stirring for 18min, after it dissolves, add thioacetamide into the mixed solution , continue to stir for 32min to obtain ladder potassium tartrate / PVP / TAA mixture solution;

[0031] 2) Put the cellulose microfiber suspension in a large beaker with ice cubes, treat it under 170W ultrasonic wave for 40s, let it stand at room temperature for 8min after the treatment, and then titrate the cellulose microfiber suspension to chlorine with a glass syringe. In the calcium chloride solution, soak the obtained spherical cellulose wet gel in tert-butanol solution for solvent replacement, and vacuum freeze-dry after the replacement is complete, to obtain spherical cellulose aerogel;

[0032] 3) Put zinc sulfate hep...

Embodiment 3

[0039] A preparation method of network structure nano-zinc oxide, the specific preparation method is as follows:

[0040] 1) Add antimony potassium tartrate into deionized water, stir at 180r / min for 10min, make it fully dissolved, add polyvinylpyrrolidone, continue stirring for 15min, after it dissolves, add thioacetamide into the mixed solution , and continue to stir for 30min to obtain ladder potassium tartrate / PVP / TAA mixture solution;

[0041] 2) Put the cellulose microfiber suspension in a large beaker with ice cubes, treat it under 180W ultrasonic wave for 30s, let it stand at room temperature for 7min after the treatment, and then titrate the cellulose microfiber suspension to chlorine with a glass syringe. In the calcium chloride solution, soak the obtained spherical cellulose wet gel in tert-butanol solution for solvent replacement, and vacuum freeze-dry after the replacement is complete, to obtain spherical cellulose aerogel;

[0042] 3) Put zinc sulfate heptahydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com