Cyclic compound and application thereof and electronic device

A technology for cyclic compounds and electronic devices, which is applied in the fields of electrical solid devices, electrical components, semiconductor devices, etc., can solve the problems of poor thermal stability, limited luminous efficiency of organic electroluminescent devices, and limited improvement of device life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

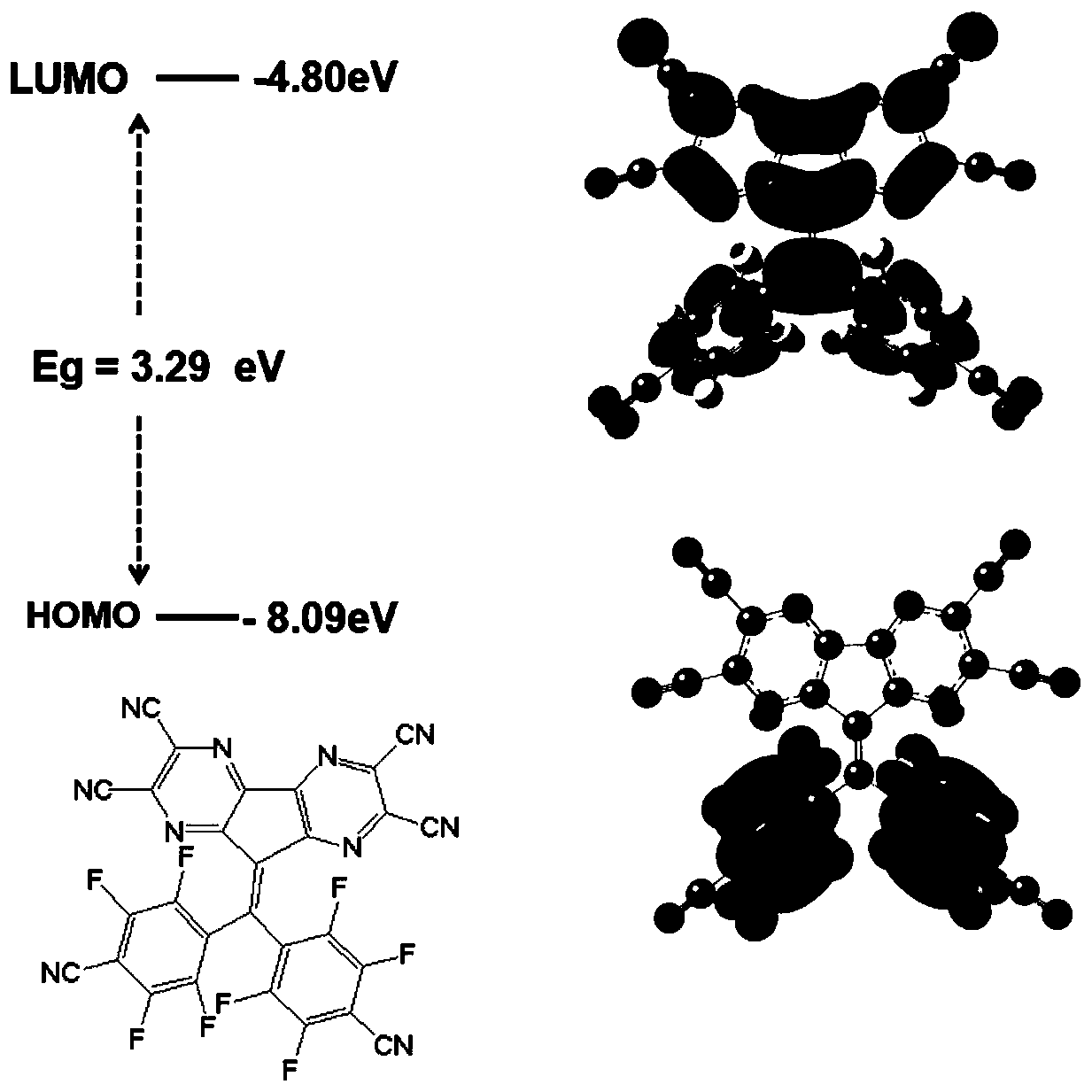

Image

Examples

Embodiment 1

[0071] This embodiment provides a cyclic compound having the structure shown in the following formula C1:

[0072]

[0073] The synthetic route of compound shown in formula C1 is as follows:

[0074]

[0075] The preparation method of the compound shown in formula C1 specifically comprises the following steps:

[0076] 1) Synthesis of intermediate 1-1: in a 250 ml single-necked bottle, compound N1 (19.00 g, 1 equivalent) was added under nitrogen protection to dissolve in 50 ml of absolute ethanol, and potassium carbonate (14.49 g, 1.05 equivalent) was added . Compound M1 (8.80 g, 1 equivalent), stirred at room temperature for 4 hours. Add 50 ml of water to quench, spin to dry the solvent, extract with ethyl acetate (100 ml × 3), and spin to dry the organic solvent to obtain a crude product, which is purified by chromatography (the volume ratio of ethyl acetate / hexane is 1 / 20 ), to obtain intermediate 1-1 (21.32 g, yield 82%).

[0077] 2) Synthesis of intermediate 2-1:...

Embodiment 2

[0081] This embodiment provides a cyclic compound having the structure shown in the following formula C2:

[0082]

[0083] The synthetic route of compound shown in formula C2 is as follows:

[0084]

[0085] The preparation method of the compound shown in formula C2 specifically comprises the following steps:

[0086] 1) Synthesis of intermediate 1-2: in a 250 ml single-necked bottle, under nitrogen protection, compound N2 (10.80 g, 1 equivalent) was dissolved in 50 ml of absolute ethanol, and potassium carbonate (14.49 g, 1.05 equivalent) was added . Compound M2 (11.60 g, 1 equivalent), stirred at room temperature for 4 hours. Add 50 ml of water to quench, spin to dry the solvent, extract with ethyl acetate (100 ml × 3), and spin to dry the organic solvent to obtain a crude product, which is purified by chromatography (the volume ratio of ethyl acetate / hexane is 1 / 20 ), to obtain intermediate 1-2 (14.85 g, yield 79%).

[0087] 2) Synthesis of intermediate 2-2: In a ...

Embodiment 3

[0091] This embodiment provides an intermediate compound, and its synthetic route is as follows:

[0092]

[0093] 1) Synthesis of intermediate 1': In a 250 ml three-necked flask, add 4,5-dihydroxycyclopent-4-ene-1,2,3-trione (14.21 g, 1 equivalent) under nitrogen protection, 2,3-diamino-2-butenedinitrile (10.80 g, 1 equivalent), acetic acid (100 ml), reacted at 40°C for 4 hours, cooled to room temperature, added 150 ml of water to quench, ethyl acetate ( 150 ml × 3) extraction, the organic phase was dried with anhydrous sodium sulfate, and the organic solvent was spin-dried to obtain a crude product. The crude product was purified by chromatography (ethyl acetate / hexane volume ratio 1 / 10) to obtain intermediate 1' (14.98 g, yield 70%).

[0094] 2) Synthesis of intermediate 2': In a 250 ml three-necked flask, intermediate 1' (21.40 g, 1 equivalent) and 50 ml of nitric acid were added under nitrogen protection, and reacted at room temperature for 2 hours. After the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com