Amphiphilic biochar compound with anti-bacterial and anti-coagulation properties and preparing method and application thereof

A carbon composite and biophilic technology, applied in anticoagulant treatment, carbon preparation/purification, drug delivery, etc., can solve the problems of short action time and inconvenient use of impregnation method, and achieve inhibition of catheter-related infection , good antibacterial properties, and the effect of inhibiting platelet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

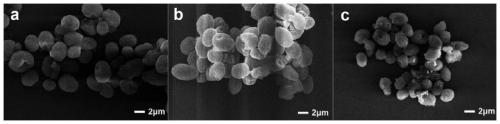

[0051] (1) Preparation of amphiphilic carbon materials (ACPs): Weigh 50.0 g of brewer’s yeast cells, add 200 mL of deionized water to disperse them evenly, let stand at room temperature for 10 min, remove impurities and floating matter on the surface of the liquid, and filter out the upper layer The dispersion was centrifuged at 8000rpm for 3min, then the supernatant was discarded, and acetone was added to the sediment in the lower layer, and then fully stirred with a glass rod until it was uniformly dispersed, then fully stirred with a glass rod until it was uniformly dispersed, and then placed on a shaker Shake for 20 minutes, centrifuge again and add acetone to evenly disperse and repeat the above operation twice to remove the contents of yeast cells; then wash with deionized water three times to remove the residual acetone solvent. Finally, the precipitate was added to the previously prepared 2% glutaraldehyde-phosphate buffer solution and dispersed evenly, and finally pour...

Embodiment 2

[0062] Example 2 Preparation of TPU / ACPs-Ag / ACPs-Hep Antibacterial Silicone Rubber Catheter

[0063] 1. Preparation of antibacterial silicone rubber catheter

[0064] Weigh 25 mg of ACPs-Ag and ACPs-Hep amphiphilic bio-carbon particles, add them to 5 g of silicone rubber liquid at a mass fraction of 1:100, and mix well. Afterwards, a novel antibacterial catheter is made according to the preparation process of a conventional catheter.

[0065] 2. To verify the antibacterial and anticoagulant properties of ACPs-Ag / ACPs-Hep antibacterial silicone rubber catheter. Antibacterial results such as Figure 14 , ACPs-Ag / ACPs-Hep antibacterial silicone rubber catheter has good antibacterial effect on Staphylococcus aureus, Escherichia coli, Candida albicans and drug-resistant Staphylococcus aureus; the anticoagulant results are as follows Figure 15 , ACPs-Ag / ACPs-Hep antibacterial silicone rubber catheter has strong anti-platelet adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com