Seamless expansion joint filling material sealant and preparing method and application thereof

A seamless expansion and joint filling technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of debonding and water seepage of the paving layer, unsatisfactory use effect, and high price. Improve the interface bonding performance, avoid the generation and cracking of internal stress, and enhance the effect of bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

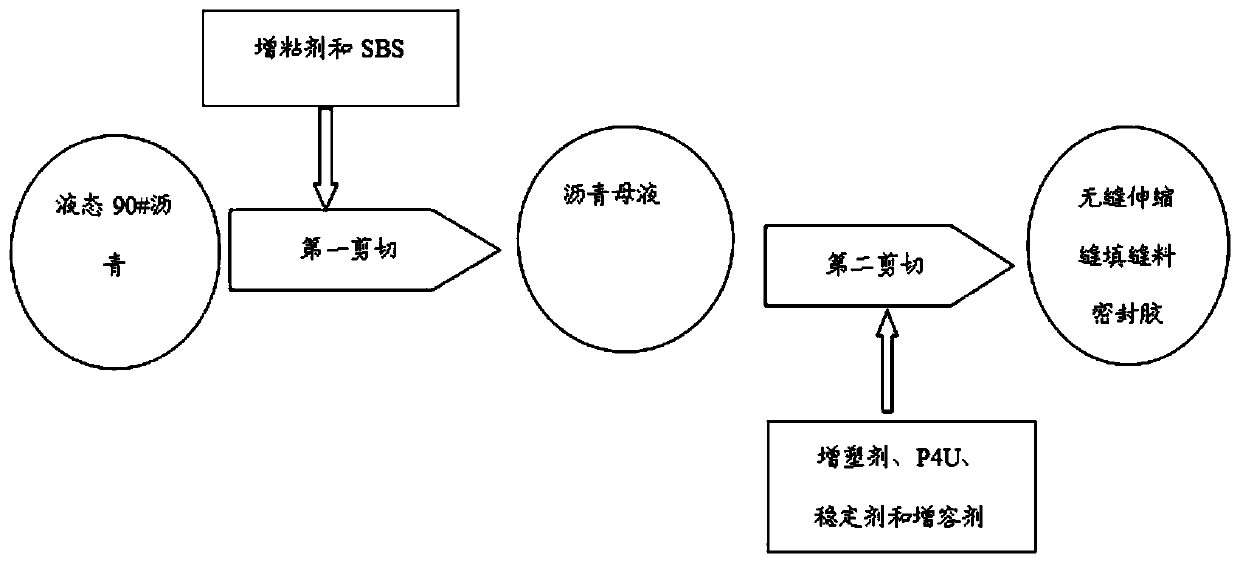

[0036] The present invention also provides a preparation method of the seamless expansion joint sealant described in the above technical solution, comprising the following steps:

[0037] Liquid 90 # Asphalt, tackifier and styrene-butadiene-styrene block copolymer are mixed for the first shear to obtain asphalt mother liquor;

[0038] The asphalt mother liquor, plasticizer, toughening agent P4U, stabilizer and compatibilizer are mixed for second shearing to obtain the seamless expansion joint sealant.

[0039] The present invention will liquid 90 # The asphalt, the tackifier and the styrene-butadiene-styrene block copolymer are mixed for the first shearing to obtain the asphalt mother liquor.

[0040] In the present invention, the liquid 90 # The temperature of the pitch is preferably 165 to 170°C. In the present invention, the first shearing is preferably carried out in a colloid mill, the rate of the first shearing is preferably 6000-8000r / min, which can be adjusted acco...

Embodiment 1

[0048] According to the number of parts by mass, weigh 100 parts 90 # Bitumen, 1 part terpene resin, 4 parts SBS, 2 parts dioctyl phthalate, 4 parts toughening agent P4U, 0.3 part sodium carboxymethylcellulose, and 0.3 part butadiene.

[0049] Add terpene resin and SBS to liquid 90 at 165°C # Asphalt is milled at a high speed in a colloid mill with a shear rate of 6000r / min. After shearing, the asphalt mother liquor is obtained. The particle size of the asphalt mother liquor is 10-30μm, the viscosity is 79752Pa.S, and the elastic recovery is 91.6%.

[0050] After the asphalt mother liquor was kept at 180°C for 2 hours, it was mixed with dioctyl phthalate, P4U, sodium carboxymethyl cellulose and butadiene, and then dispersed in a high-speed shearing machine with a shear rate of 5000r / min, to obtain seamless expansion joint filler sealant.

[0051] The performance of the obtained seamless expansion joint sealant was tested, and the test results are shown in Table 1.

Embodiment 2

[0053] According to the number of parts by mass, weigh 100 parts 90 # Bitumen, 2 parts rosin resin, 6 parts SBS, 2 parts dibutyl phthalate, 2 parts toughener P4U, 0.5 part polyvinyl alcohol, and 0.5 part styrene.

[0054] Add rosin resin and SBS to liquid 90 at 170°C # Asphalt is milled at a high speed in a colloid mill with a shear rate of 8000r / min, and the asphalt mother liquor is made by shearing. The particle size of the asphalt mother liquor mixture is 10-30μm, the viscosity is 276453Pa.S, and the elastic recovery is 98.4%.

[0055] After the asphalt mother liquor was kept at 180°C for 2 hours, it was grafted with dibutyl phthalate, P4U, polyvinyl alcohol and starch to carry out high-speed shear dispersion in a high-speed shearing machine at a shear rate of 6000r / min, get the seamless expansion joint sealant.

[0056] The performance of the obtained seamless expansion joint sealant was tested, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com