Deodorizing filler and preparation method thereof, deodorizing device, deodorizing method, and application

A technology based on the main body and microorganisms, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of long start-up time of reactors, increased operating costs, and poor mechanical properties, and achieves good adsorption and release effects. Will cause secondary pollution, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In some preferred embodiments, the preparation method includes the following steps:

[0052] (a) Making clay and dewatered sludge into powder with a particle size of 0.4 to 0.6mm;

[0053] (b) mix organic mineral powder, clay powder, dewatered sludge powder and microbial dry powder, binder according to formula quantity;

[0054] (c) Soak the fly ash in the Thiobacillus liquid acclimated by the biological trickling filter tower according to the formula, and add the nitrifying bacteria liquid, microbial nutrients and trace metal liquid according to the formula, and add the step (b) after mixing evenly ) the mixture obtained to obtain a mixed slurry; the trace metal liquid is a solution containing the metal ion;

[0055] (d) Granulating the mixed slurry, preferably extruding and granulating the mixed slurry through a flat film to obtain a cylindrical filler. The size of the filler is preferably: the diameter of the filler is 1 cm to 5 cm, the length is 2 cm to 10 cm, and ...

Embodiment 1

[0063] This embodiment provides a deodorant filler, which includes a filler body, a microbial agent, microbial nutrients and metal ions, and the components are as follows:

[0064] The filler body, according to the mass percentage of the filler body, includes the following components: 40% of fly ash, 25% of clay, 15% of dewatered sludge, 10% of organic mineral powder and 10% of resin binder.

[0065] Microbial agent: including Thiobacillus, yeast, Bacillus subtilis, Pseudomonas putida and nitrifying bacteria; add 5g of microbial dry powder per kilogram of the filler body, and in terms of mass percentage, the microbial dry powder includes Bacillus subtilis 30% of microbial dry powder, 40% of Pseudomonas putida microbial dry powder and 30% of yeast microbial dry powder; every 3kg of fly ash is soaked in 2L of Thiobacillus bacteria liquid to absorb Thiobacillus, and the Thiobacillus bacteria liquid is filtered by biological trickling The filtrate after tower acclimatization; add ...

Embodiment 2

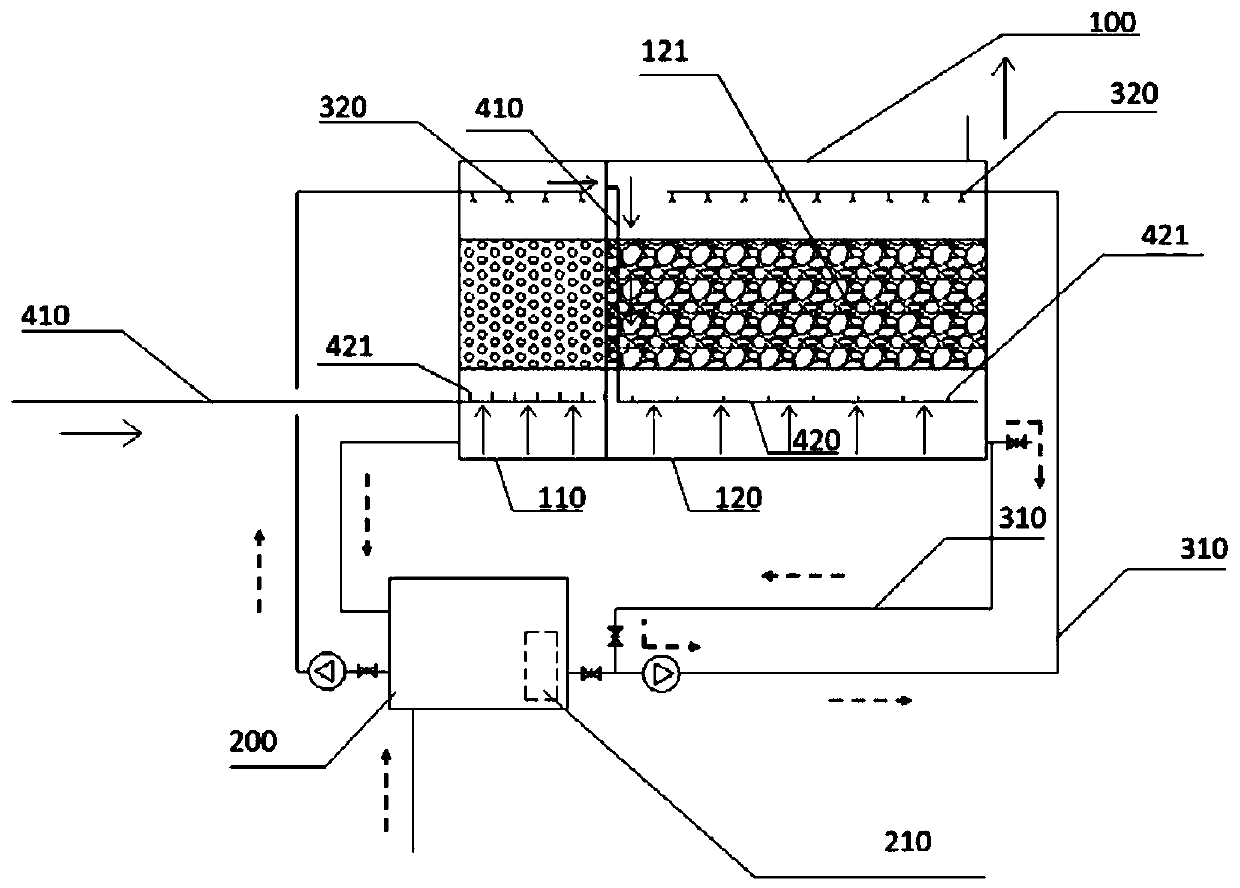

[0098] This embodiment provides a deodorization device, the schematic diagram of the deodorization device is as follows figure 1 , where the solid arrows indicate the flow direction of gas, and the dashed arrows indicate the flow direction of water.

[0099] The deodorizing filler 121 provided by the embodiment 1 that the stuffing of the bioreaction section 120 of the biofilter 100 of this deodorization device uses, and is provided with internal circulation pipeline 310 in biological reaction section 120, and internal circulation pipeline 310 makes biological reaction The water below the air distribution device 420 of the section 120 returns to the spray device 320 of the biological reaction section 120 through the internal circulation pipeline 310, and is sprayed out again, so that the water in the biological reaction section 120 and the deodorizing bacteria agent in the water are obtained. Recycling.

[0100] For the water tank 200 of biological filter 100 water supply, pac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com