Preparation method of epoxy/polyester powdery paint which contains glass fiber and possesses self-healing capacity

A technology of glass fiber and epoxy, applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., can solve the problems of short life and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

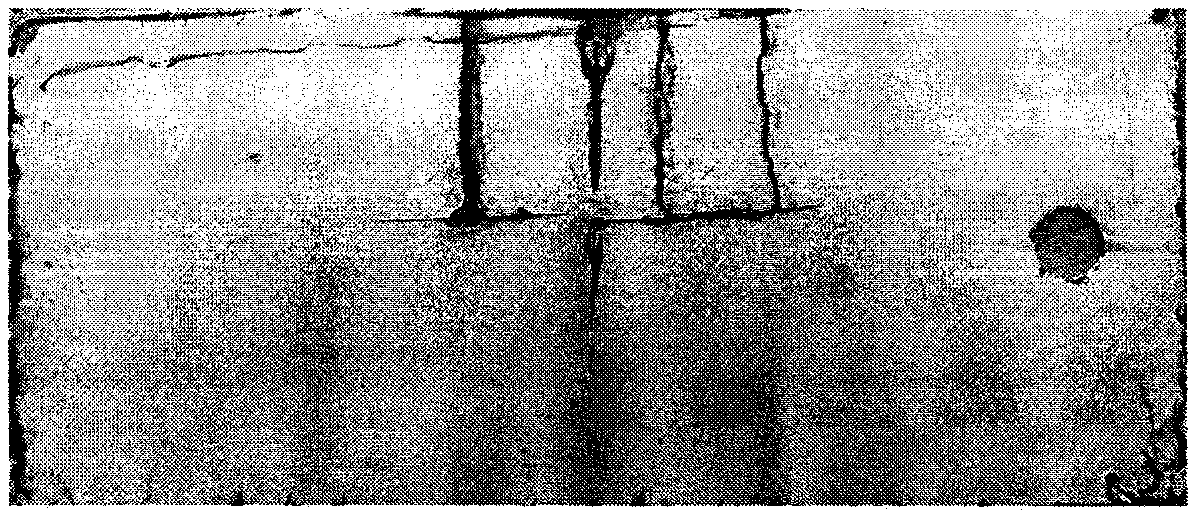

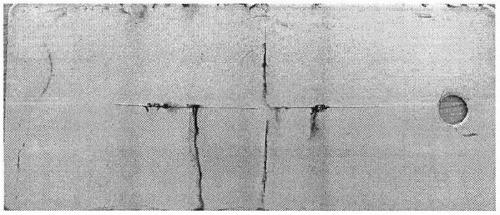

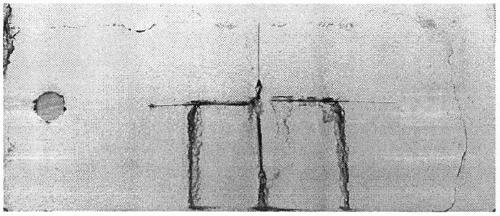

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of epoxy / polyester composite powder coating that has self-healing ability and contains glass fiber, it is characterized in that preparation method comprises the following steps:

[0024] 1) Ingredients pre-mixed

[0025] Put each component into the high-speed pulverizer for pre-mixing according to the following ratio:

[0026] Carboxyl-terminated polyester (new Chinese method P5086AME) 165 parts

[0027] 30 parts of homemade unsaturated polyester

[0028] E12 bisphenol A glycidyl ether epoxy resin (Anhui Shanfu 604U) 200 parts

[0029] 30 parts glass fiber

[0030] Dicumyl peroxide (DCP) 0.03 parts by weight

[0031] 0.03 parts by weight of ethyl triphenylphosphine bromide

[0032] Titanium dioxide 50 parts

[0033] Barium sulfate 50 parts

[0034] Leveling agent 4 to 5 parts

[0035] Benzoin 1.5~2 parts

[0036] 701B 4~6 copies

[0037] Polyethylene wax (Nanjing Tianshi New Material Technology Co., Ltd.) 15 parts

[0038] PTFE wax (Nanji...

Embodiment 2

[0049] Embodiment 2: a kind of epoxy / polyester composite powder coating that has self-healing ability and contains glass fiber, it is characterized in that preparation method comprises the following steps:

[0050] 1) Ingredients pre-mixed

[0051] Put each component into the high-speed pulverizer for pre-mixing according to the following ratio:

[0052] Carboxyl-terminated polyester (new Chinese method P5086AME) 175 parts

[0053] Homemade unsaturated polyester 25 parts

[0054] E12 bisphenol A glycidyl ether epoxy resin (Anhui Shanfu 604U) 200 parts

[0055] 35 parts glass fiber

[0056] Dicumyl peroxide (DCP) 0.03 parts by weight

[0057] 0.04 parts by weight of ethyl triphenylphosphine bromide

[0058] Titanium dioxide 60 parts

[0059] Barium sulfate 40 parts

[0060] Leveling agent 4 to 5 parts

[0061] Benzoin 1.5~2 parts

[0062] 701B 4~6 copies

[0063] Polyethylene wax (Nanjing Tianshi New Material Technology Co., Ltd.) 15 parts

[0064] PTFE wax (Nanjing ...

Embodiment 3

[0075] Embodiment 3: a kind of epoxy / polyester composite powder coating that has self-healing ability and contains glass fiber, it is characterized in that preparation method comprises the following steps:

[0076] 1) Ingredients pre-mixed

[0077] Put each component into the high-speed pulverizer for pre-mixing according to the following ratio:

[0078] Carboxyl-terminated polyester (new Chinese method P5086AME) 180 parts

[0079] Homemade unsaturated polyester 25 parts

[0080] E12 bisphenol A glycidyl ether epoxy resin (Anhui Shanfu 604U) 200 parts

[0081] 30 parts glass fiber

[0082] Dicumyl peroxide (DCP) 0.03 parts by weight

[0083] 0.04 parts by weight of ethyl triphenylphosphine bromide

[0084] Titanium dioxide 60 parts

[0085] Barium sulfate 40 parts

[0086] Leveling agent 4 to 5 parts

[0087] Benzoin 1.5~2 parts

[0088] 701B 4~6 copies

[0089] Polyethylene wax (Nanjing Tianshi New Material Technology Co., Ltd.) 15 parts

[0090] PTFE wax (Nanjing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com