A kind of determination method of hydrogen cyanide in coke oven gas

A coke oven gas and determination method technology, which is applied in the direction of measuring devices, preparation of test samples, chemical analysis by titration, etc., can solve the problems of complex steps, long time-consuming, toxic and harmful, etc., so as to improve the accuracy of analysis, Effect of shortened analysis cycle and high hydrogen sulfide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

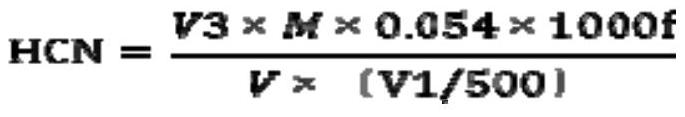

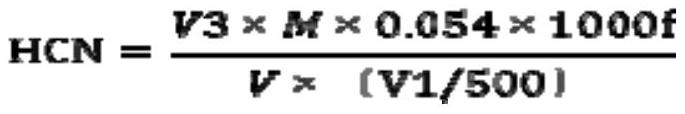

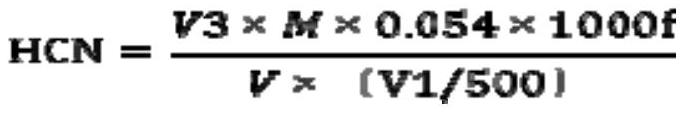

Image

Examples

Embodiment 1

[0032] The assay method of hydrogen cyanide in the coke oven gas of the present embodiment comprises:

[0033] (1) Calibrate the wet gas flowmeter, connect it with the gas pipeline and disperse the gas for 5 minutes, and connect the gas pipeline, the pretreatment gas cleaning bottle with lead acetate solution, the sampling gas cleaning bottle with sodium hydroxide solution, and the wet gas flowmeter. Connected in turn through the gas pipe; the concentration of the lead acetate solution is 40g / L, and the volume is 120mL, and the concentration of the sodium hydroxide solution is 15wt%, and the volume is 120mL;

[0034] Open the valve set on the gas pipeline, pass the gas into the pretreatment gas washing bottle and the sampling gas cleaning bottle in turn for sampling, control the gas flow rate to be 1L / min, and the sampling volume to be 50L. After sampling, record the wet Gas flow meter readings and gas temperature and pressure;

[0035] (2) All the absorbing liquids in the sa...

Embodiment 2

[0047] The assay method of hydrogen cyanide in the coke oven gas of the present embodiment comprises:

[0048] (1) Calibrate the wet gas flowmeter, connect it with the gas pipeline and disperse the gas for 10 minutes, and connect the gas pipeline, the pretreatment gas cleaning bottle with lead acetate solution, the sampling gas cleaning bottle with sodium hydroxide solution, and the wet gas flowmeter. Connected in turn through the gas pipe; the concentration of the lead acetate solution is 60g / L, and the volume is 80mL, and the concentration of the sodium hydroxide solution is 25wt%, and the volume is 80mL;

[0049] Open the valve set on the gas pipeline, pass the gas into the pretreatment gas washing bottle and the sampling gas cleaning bottle in turn for sampling, control the gas flow to be 2L / min, and the sampling volume to be 60L. After sampling, record the wet type Gas flow meter readings and gas temperature and pressure;

[0050] (2) All the absorbing liquids in the sam...

Embodiment 3

[0062] The assay method of hydrogen cyanide in the coke oven gas of the present embodiment includes:

[0063] (1) Calibrate the wet gas flowmeter, connect it with the gas pipeline and disperse the gas for 8 minutes, and connect the gas pipeline, the pretreatment gas cleaning bottle containing lead acetate solution, the sampling gas cleaning bottle containing sodium hydroxide solution, and the wet gas flowmeter Connected in turn through the gas pipe; the concentration of lead acetate solution is 50g / L, and the volume is 100mL, and the concentration of sodium hydroxide solution is 20wt%, and the volume is 100mL;

[0064] Open the valve set on the gas pipeline, pass the gas into the pretreatment gas washing bottle and the sampling gas cleaning bottle in turn for sampling, control the gas flow rate to be 1.5L / min, and the sampling volume to be 55L. After sampling, record the The readings of the wet gas flow meter and the temperature and pressure of the gas;

[0065] (2) All the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com