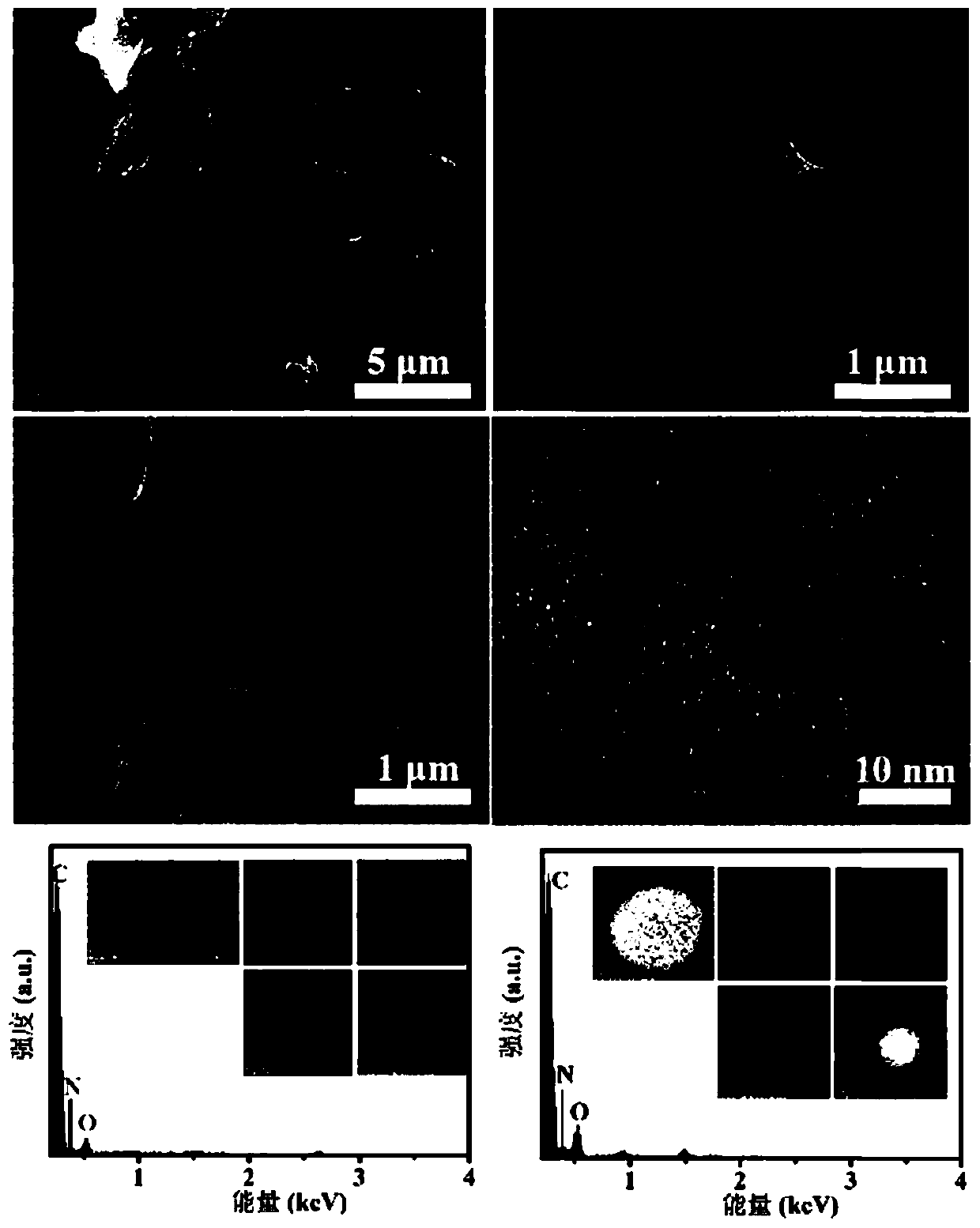

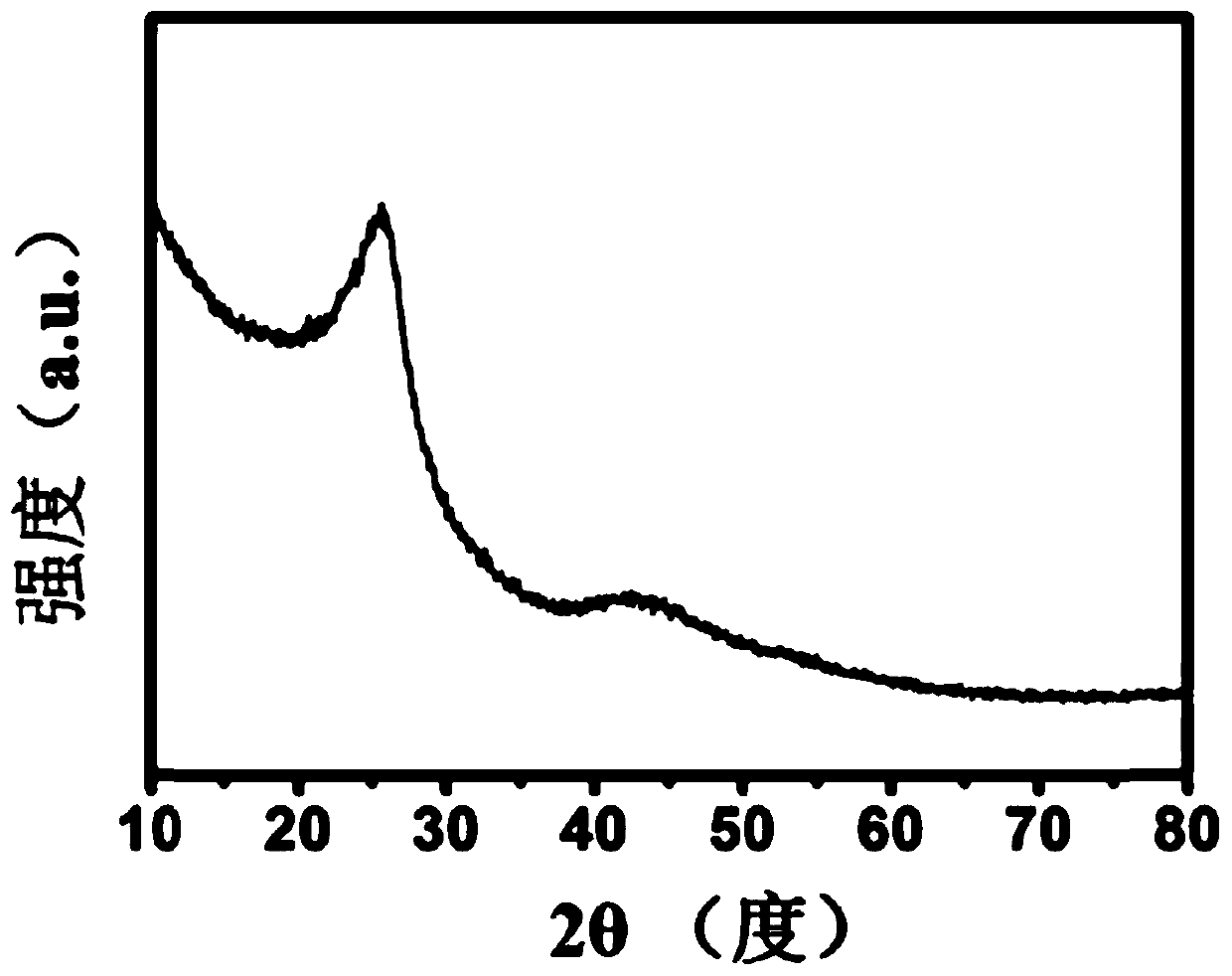

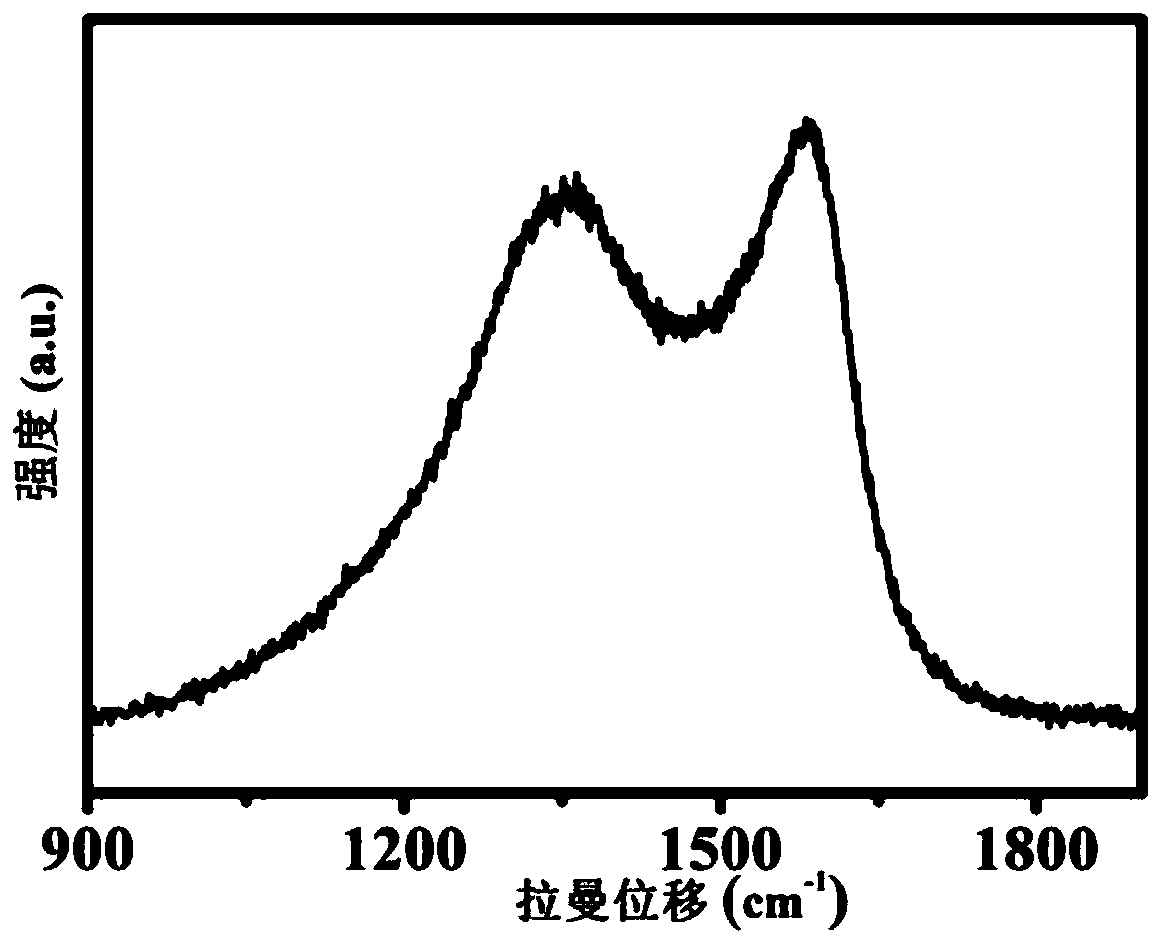

Large current charge/discharge nitrogen-oxygen co-doped spherical/sheet-like porous carbon material and application thereof in supercapacitor electrode material

A technology of porous carbon materials and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, carbon preparation/purification, etc., can solve problems such as limited application and industrial production, high cost, and difficulty in mass production , to achieve the effect of huge application potential and industrial value, excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] S1: Hexabromobenzene and pyridine were subjected to closed reaction at a reaction pressure of 3MPa and 200°C for 6 hours; wherein, the mass ratio of hexabromobenzene to pyridine was 80:1;

[0056] S2: After the reaction, the pressure was released to normal pressure, and naturally cooled to room temperature, the obtained solid was fully washed 3 times with petroleum ether, and vacuum-dried at 40°C for 10 hours to obtain a dry sample;

[0057] S3: The dried sample was treated at a high temperature of 1000°C for 2 hours under the protection of nitrogen to obtain the nitrogen-oxygen co-doped sphere / sheet porous carbon material, which was named SL1.

Embodiment 2-3

[0058] Embodiment 2-3: the investigation of reaction ratio in the step S1

[0059] Except that the quality of the reaction-free hexabromobenzene in step S1 is replaced by 2g and 6g respectively, other operations are all the same, so that the embodiment 2-3 is carried out successively, and the obtained nitrogen-oxygen co-doped ball / sheet porous carbon The materials were named SL2 and SL3 in turn.

Embodiment 4-6

[0060] Embodiment 4-6: the investigation of high temperature treatment temperature in step S3

[0061] Except that the high-temperature treatment temperature in step S3 was replaced by 800°C, 900°C, and 1100°C, the other operations remained unchanged, so that Examples 7-9 were carried out in sequence, and the obtained nitrogen-oxygen co-doped ball / sheet porous The carbon materials are named SL4, SL5 and SL6 in turn.

[0062] Preparation of capacitor electrodes

[0063] The preparation method of the capacitor electrode comprises the following steps:

[0064] (A) Weigh nitrogen-oxygen co-doped ball / sheet porous carbon material SL1, PTFE (polytetrafluoroethylene) emulsion (the mass ratio of the two is 9:1, due to the good electrical conductivity of the material, during the preparation of the electrode There is no need to add additional conductive agent), add an appropriate amount of ethanol, mix well, and when stirring continuously into a paste, apply it to foamed nickel and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com