Preparation method of TiO2/wollastonite compound

A technology of wollastonite and composites, which is applied in the field of preparation of TiO2/wollastonite composites, which can solve the problems of resource saving, large amount of TiO2 added, poor coating effect, etc., and achieve weather resistance Good, high whiteness, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

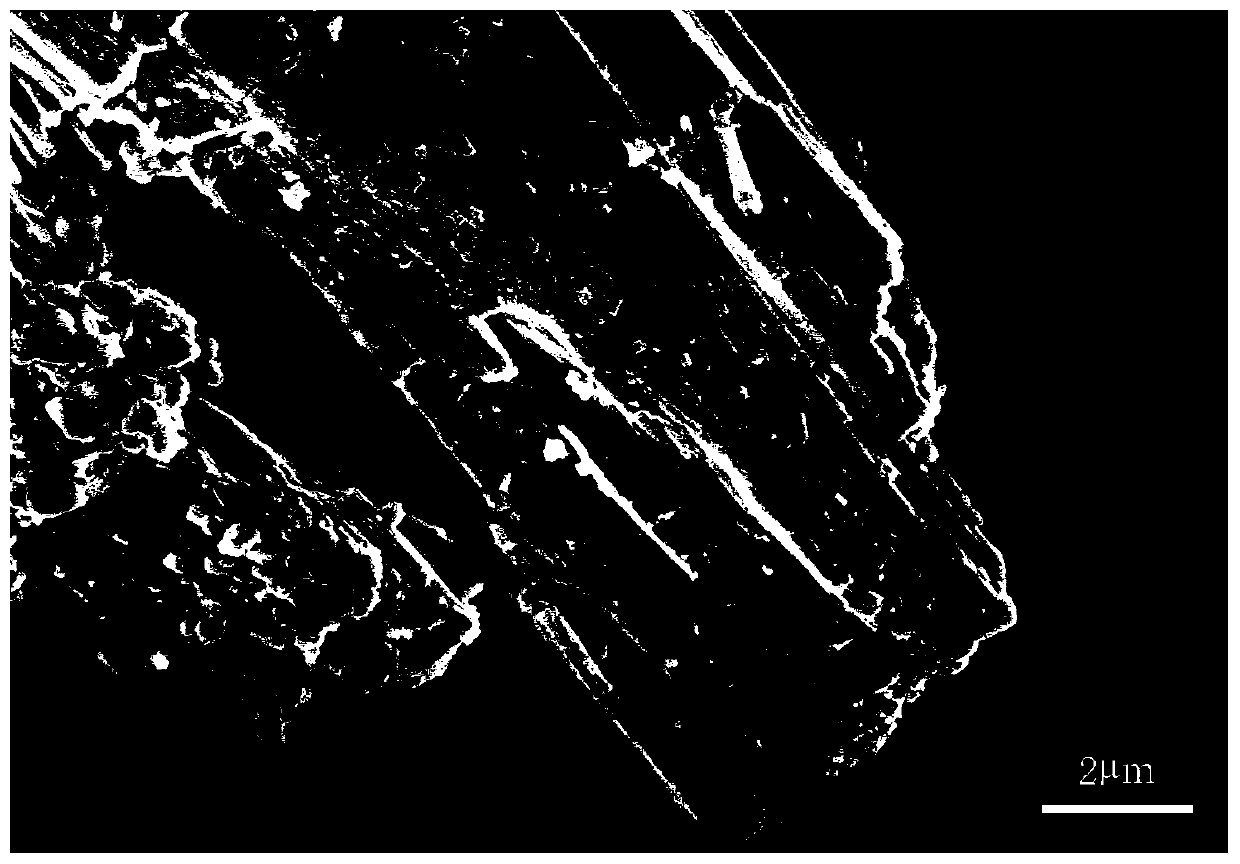

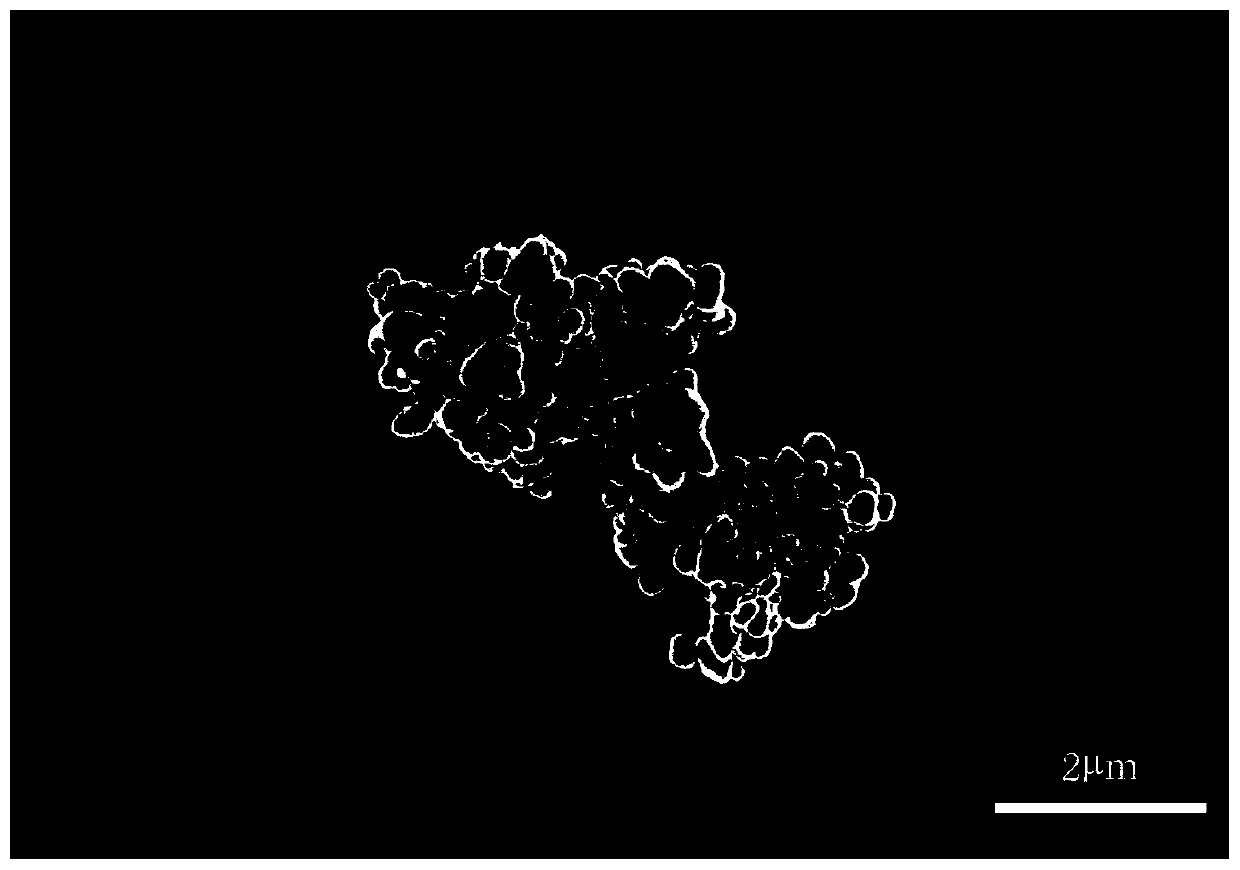

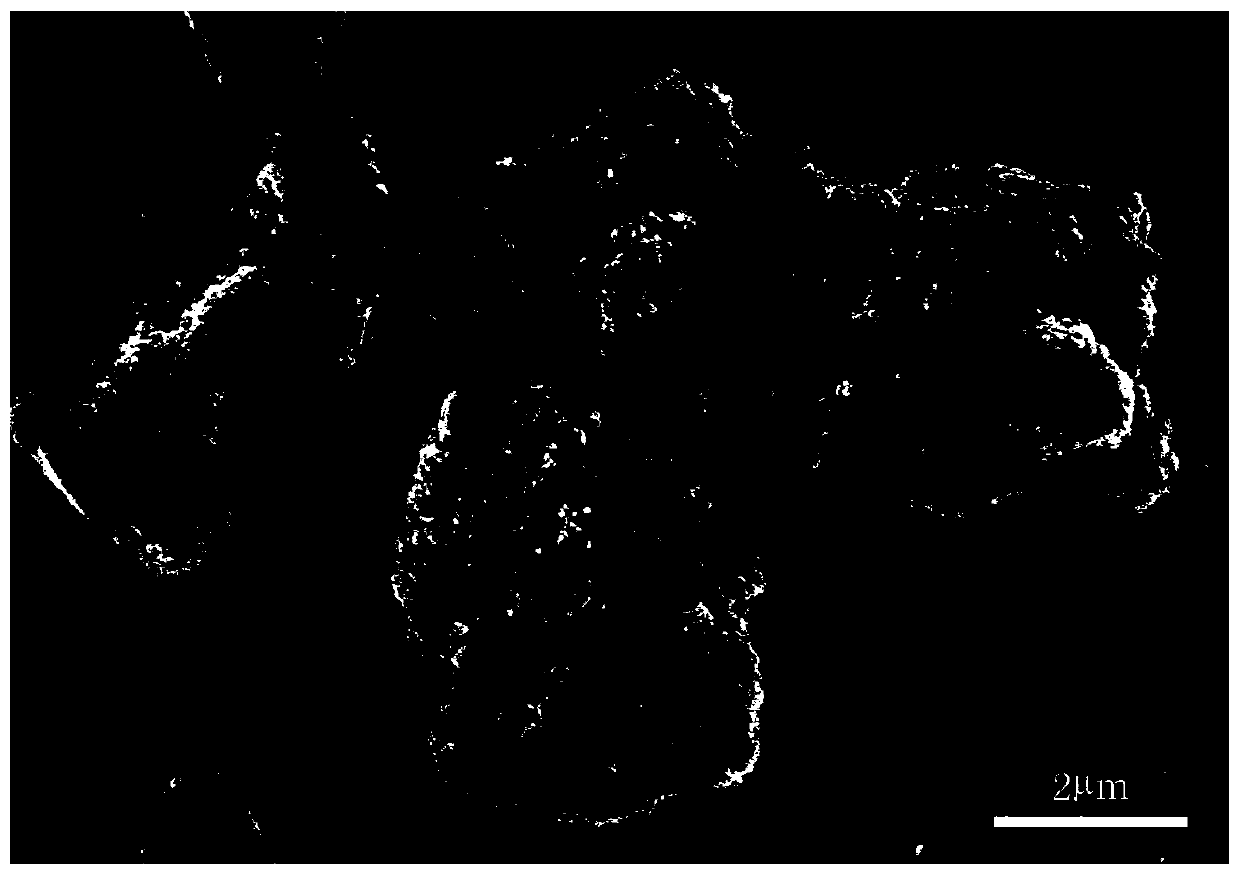

Embodiment 1

[0021] Add 60g wollastonite to 250mL distilled water, stir at 15°C for 30min, add polyacrylic acid emulsion, the amount of polyacrylic acid emulsion added is 1% of the mass of wollastonite, stir in a water bath at 15°C for 30min, add 9g rutile titanium dioxide, 0.01g dispersant PEG-1000, stirred in a water bath at 15°C for 1 hour to obtain a white slurry, vacuum filtered and dried in an oven at 80°C for 12 hours to obtain a TiO2 / wollastonite composite product; the whiteness of the obtained TiO2 / wollastonite composite product The value is 92.3.

Embodiment 2

[0023] Add 60g wollastonite to 250mL distilled water, stir at 15°C for 30min, add polyvinyl alcohol, the amount of polyvinyl alcohol added is 1% of the mass of wollastonite, stir in a water bath at 15°C for 30min, add 9g rutile titanium dioxide, 0.01g dispersant PEG-1000, stirred in a water bath at 15°C for 1 hour to obtain a white slurry, vacuum filtered and dried in an oven at 80°C for 12 hours to obtain a TiO2 / wollastonite composite product; the whiteness of the obtained TiO2 / wollastonite composite product The value is 92.9.

Embodiment 3

[0025] Add 60g wollastonite to 250mL distilled water, stir at 15°C for 30min, add polyacrylamide, the amount of polyacrylamide added is 1% of the mass of wollastonite, stir in a water bath at 15°C for 30min, add 9g rutile titanium dioxide, 0.01g dispersant PEG-1000, stirred in a water bath at 15°C for 1 hour to obtain a white slurry, vacuum filtered and dried in an oven at 80°C for 12 hours to obtain a TiO2 / wollastonite composite product; the whiteness of the obtained TiO2 / wollastonite composite product The value is 92.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com