Alkali-resistant dual-network hydrogel flexible electrolyte and preparation method and application thereof

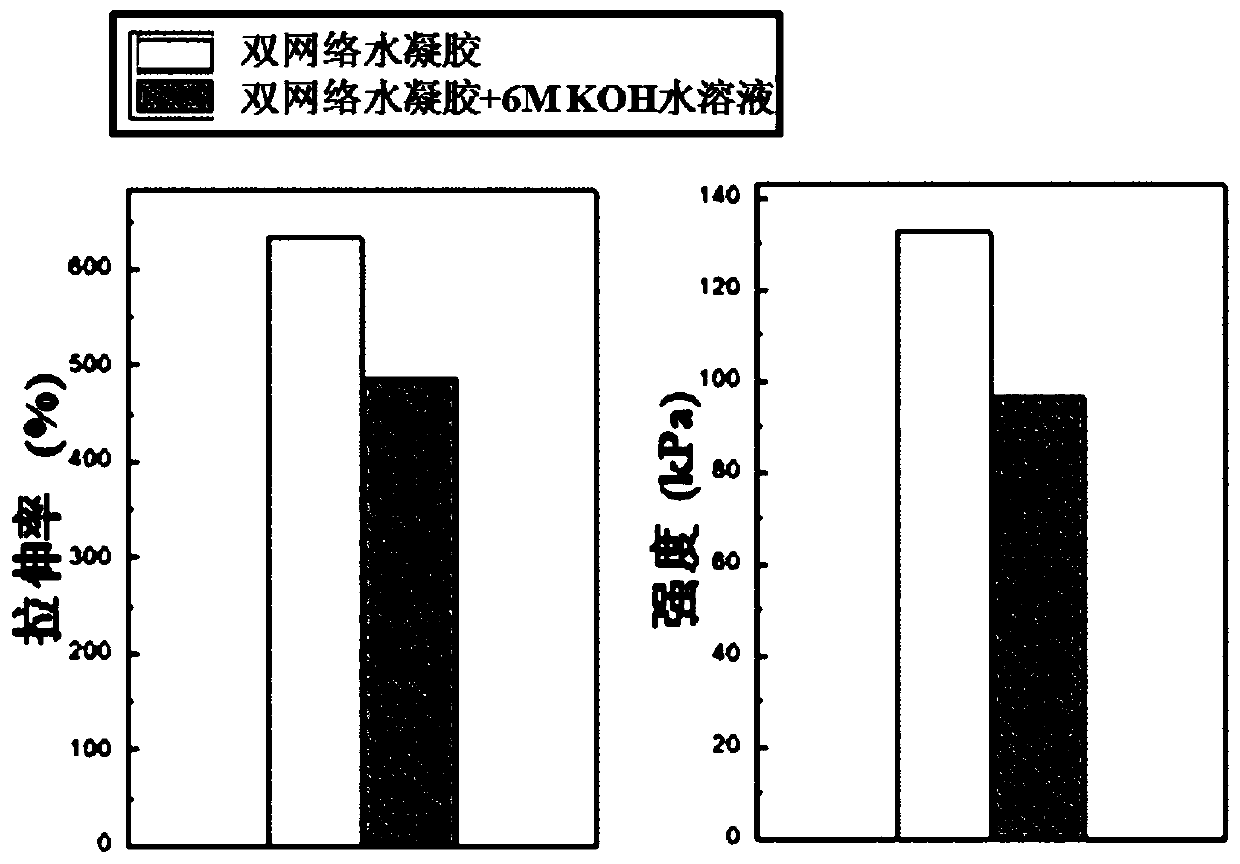

A flexible electrolyte, dual network technology, applied in the direction of electrolyte immobilization/gelation, fuel cell-type half-cell and primary battery-type half-cell, circuits, etc., can solve the problem of poor stretchability, electrochemical performance and mechanical properties Problems such as poor flexibility and loss of mechanical strength, to achieve excellent flexibility, good cross-linking effect, and enhanced mechanical durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Synthesis of water-based hexamethylene diisocyanate trimer (WHT)

[0041] In the synthesis of aqueous hexamethylene diisocyanate trimer, polyethylene glycol monomethyl ether 5g (molecular weight 750, Anaiji E080730) and hexamethylene diisocyanate trimer 5g (molecular weight 500, Shenzhen Zhibang ) for feeding, stirring and reacting at 75° C. for 12 hours to obtain aqueous hexamethylene diisocyanate trimer.

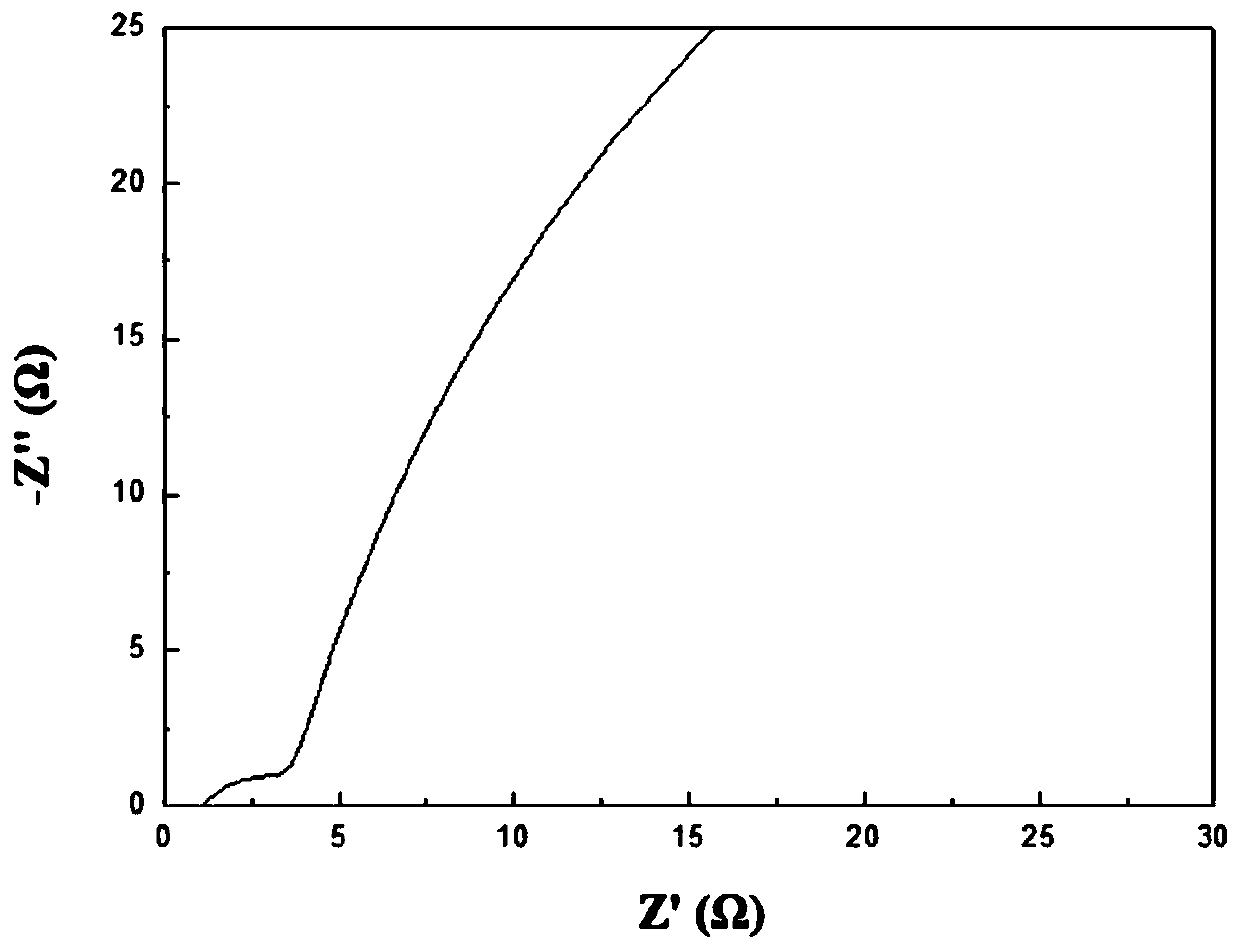

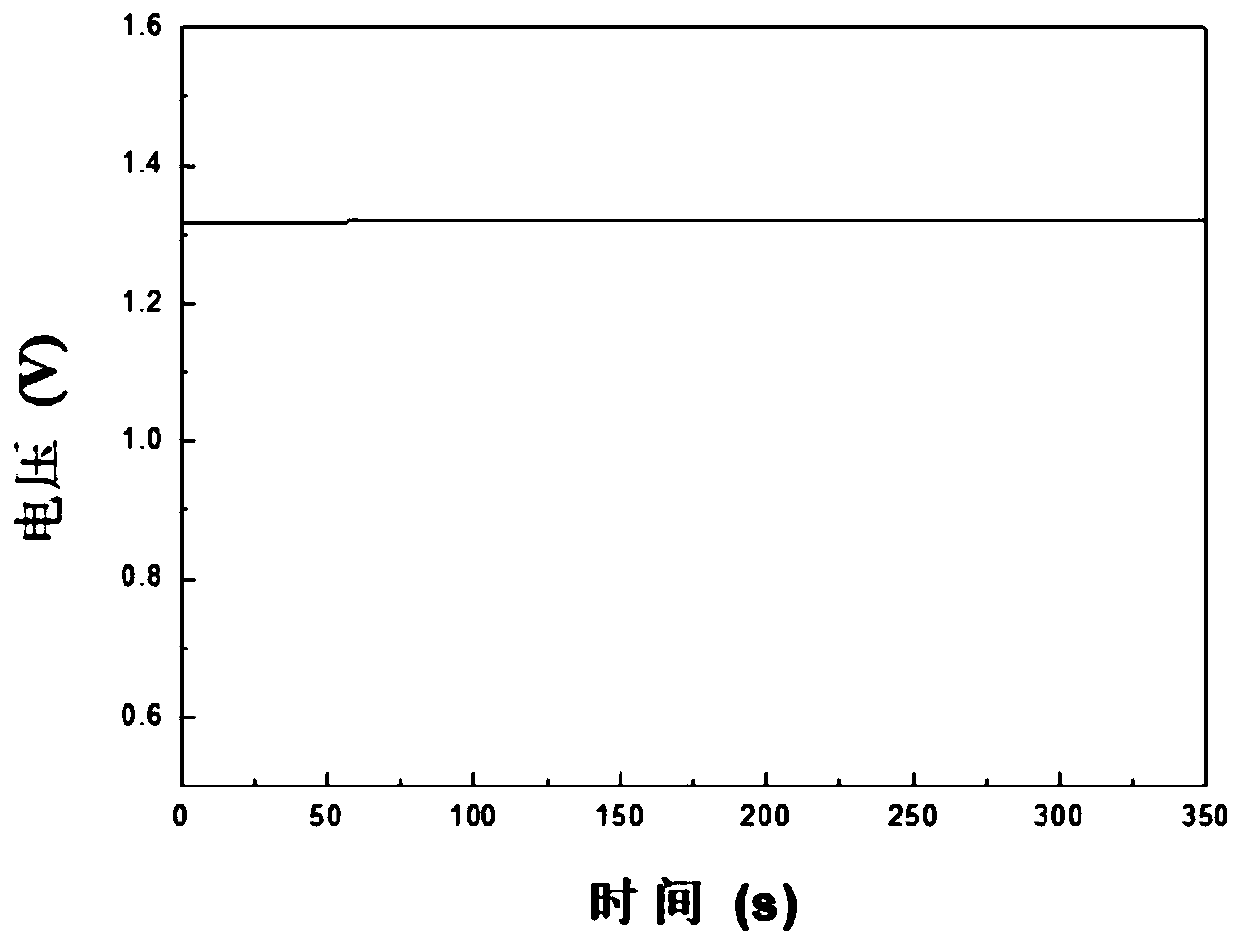

[0042] (2) Preparation of alkali-resistant double network hydrogel flexible hydrogel electrolyte

[0043] 50 microliters of hydrochloric acid (37%) was added to 25 g of deionized water, and the pH of the obtained hydrochloric acid aqueous solution was about 1. Add 0.1g of chitosan (deacetylation degree ≥ 95%, viscosity 100-200mpa.s) into hydrochloric acid aqueous solution and stir for 2h to clarify to obtain chitosan aqueous solution; mix 10g of acrylic acid with 15ml of aqueous solution containing 6g of sodium oxide Neutralization reaction to prepare sodium a...

Embodiment 2

[0050] (1) Synthesis of water-based hexamethylene diisocyanate trimer (WHT)

[0051] In the synthesis of water-based hexamethylene diisocyanate trimer, 5 g of polyethylene glycol monomethyl ether (molecular weight 2000) and 5 g of hexamethylene diisocyanate trimer (molecular weight 500) were fed, at 75 ° C The reaction was stirred for 12 hours to obtain aqueous hexamethylene diisocyanate trimer.

[0052] (2) Preparation of alkali-resistant double network hydrogel flexible hydrogel electrolyte

[0053] Add 50 microliters of hydrochloric acid (37%) to 25 g of deionized water, the pH of the aqueous hydrochloric acid solution is about 1, add 0.1 g of chitosan (deacetylation degree ≥ 95%, viscosity 100-200mpa.s) to the hydrochloric acid Stir in the aqueous solution for 2h to clarify to obtain the chitosan aqueous solution; 10g of acrylic acid and 15 milliliters of aqueous solution containing 6g sodium oxide are neutralized to obtain the sodium acrylate aqueous solution; then the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com