Preparation method of resin-reinforced ferrite solid waste-based broadband electromagnetic wave absorber

An electromagnetic wave and ferrite technology, applied in the field of electromagnetic functional materials, can solve problems such as unstable performance, difficulty in reaching mainstream magnetic core products, poor mechanical properties, etc., and achieve balanced performance differences, high economic benefits and environmental protection, and good electromagnetic waves The effect of absorbing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, boron phenolic resin is combined with manganese-zinc ferrite solid waste, and by purifying and modifying ferrite solid waste, and compounding with resin, a broadband electromagnetic wave with excellent mechanical properties and wave-absorbing properties is prepared. absorber. Concrete preparation method comprises the following steps:

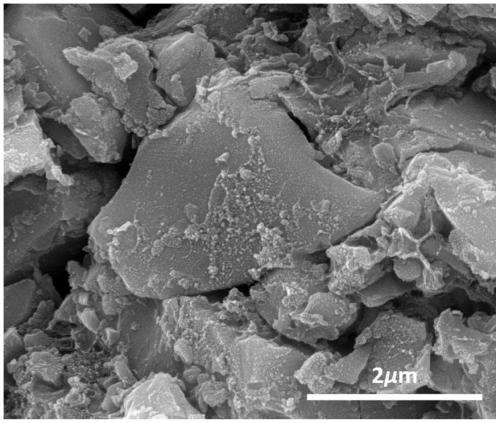

[0038] 1. Purification of soft ferrite solid waste

[0039] 1a. Take the solid waste of soft magnetic ferrite and mix it fully with water, stir and disperse it, and then sieve it to filter out some larger metal debris, corundum and other impurity particles, and then apply a magnetic field to the resulting mixed liquid to convert the magnetic soft magnet Oxygen particles are separated from the aqueous solution of non-magnetic impurities;

[0040] 1b. Repeat step 1a 5 times for the separated soft ferrite, then dry and grind to obtain purified soft ferrite powder;

[0041] 2. Homogenization of soft ferrite particles

[004...

Embodiment 2

[0050] In this example, water-based polyurethane is combined with manganese-zinc ferrite solid waste, and by purifying and modifying ferrite solid waste, and compounding it with resin, a wide-band electromagnetic wave absorber with excellent mechanical properties and wave-absorbing properties is prepared. body. Concrete preparation method comprises the following steps:

[0051] 1. Purification of soft ferrite solid waste

[0052] 1a. Take the solid waste of soft magnetic ferrite and mix it fully with water, stir and disperse it, and then sieve it to filter out some larger metal debris, corundum and other impurity particles, and then apply a magnetic field to the resulting mixed liquid to convert the magnetic soft magnet Oxygen particles are separated from the aqueous solution of non-magnetic impurities;

[0053] 1b. Repeat step 1a 5 times for the separated soft ferrite, then dry and grind to obtain purified soft ferrite powder;

[0054] 2. Homogenization of soft ferrite par...

Embodiment 3

[0063] In this example, organic silicon resin is combined with manganese zinc ferrite solid waste, and by purifying and modifying ferrite solid waste, and compounding with resin, a broadband electromagnetic wave with excellent mechanical properties and wave-absorbing properties is prepared. absorber. Concrete preparation method comprises the following steps:

[0064] 1. Purification of soft ferrite solid waste

[0065] 1a. Take the solid waste of soft magnetic ferrite and mix it fully with water, stir and disperse it, and then sieve it to filter out some larger metal debris, corundum and other impurity particles, and then apply a magnetic field to the resulting mixed liquid to convert the magnetic soft magnet Oxygen particles are separated from the aqueous solution of non-magnetic impurities;

[0066] 1b. Repeat step 1a 5 times for the separated soft ferrite, then dry and grind to obtain purified soft ferrite powder;

[0067] 2. Homogenization of soft ferrite particles

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com