Preparation method of graphite-based carbon brush material resistant to electric arc ablation

A graphite-based, arc-resistant technology, applied in circuits, current collectors, electrical components, etc., can solve problems such as arc ablation and carbon brush wear, and achieve the effect of large surface energy, increased surface activity, and a smooth feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

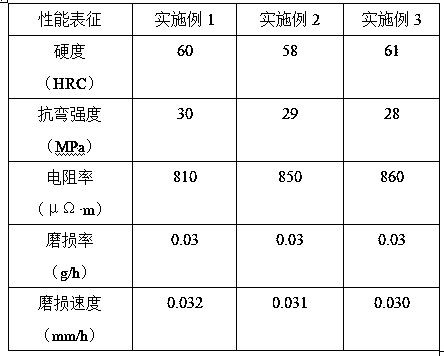

Embodiment 1

[0040] In parts by weight, weigh 30 parts of graphite, 4 parts of sodium sulfate, 2 parts of sodium carbonate, 0.8 part of sodium lauryl sulfate, 6 parts of triethanolamine, 30 parts of absolute ethanol, and 60 parts of deionized water respectively. Add absolute ethanol to deionized water, stir at 100r / min at room temperature for 6 minutes to obtain an ethanol solution, add sodium sulfate, sodium carbonate, sodium lauryl sulfate, and triethanolamine into the ethanol solution, and stir at 200r / min at room temperature Stir for 30 minutes to obtain a grinding aid, add graphite to the grinding aid, and grind for 20 hours at a speed of 180r / min at room temperature to obtain a suspension, put the suspension in a centrifuge, and centrifuge at a speed of 2500r / min at room temperature for 6 minutes, Remove the solid in the lower layer, wash with deionized water for 3 times, and dry in an oven at 60°C for 2 hours to obtain ultrafine graphite powder with an average particle size of 6 μm; ...

Embodiment 2

[0042] In parts by weight, weigh 35 parts of graphite, 5 parts of sodium sulfate, 2.5 parts of sodium carbonate, 1.0 part of sodium lauryl sulfate, 7 parts of triethanolamine, 35 parts of absolute ethanol, 70 parts of deionized water, and Add absolute ethanol to deionized water, stir at 110r / min at room temperature for 7 minutes to obtain an ethanol solution, add sodium sulfate, sodium carbonate, sodium lauryl sulfate, and triethanolamine into the ethanol solution, and stir at 220r / min at room temperature Stir for 35 minutes to obtain a grinding aid, add graphite to the grinding aid, grind for 22 hours at a speed of 190r / min at room temperature to obtain a suspension, place the suspension in a centrifuge, and centrifuge at a speed of 2750r / min for 7 minutes at room temperature, Remove the solid in the lower layer, wash it with deionized water for 4 times, and dry it in an oven at 70°C for 3 hours to obtain ultrafine graphite powder with an average particle size of 7 μm; then we...

Embodiment 3

[0044] In parts by weight, weigh 40 parts of graphite, 6 parts of sodium sulfate, 3 parts of sodium carbonate, 1.2 parts of sodium lauryl sulfate, 8 parts of triethanolamine, 40 parts of absolute ethanol, and 80 parts of deionized water respectively. Add absolute ethanol to deionized water, stir at 120r / min at room temperature for 8 minutes to obtain an ethanol solution, add sodium sulfate, sodium carbonate, sodium lauryl sulfate, and triethanolamine into the ethanol solution, and stir at 240r / min at room temperature Stir for 40 minutes to obtain a grinding aid, add graphite to the grinding aid, and grind for 24 hours at a speed of 200 r / min at room temperature to obtain a suspension, place the suspension in a centrifuge, and centrifuge at a speed of 3000 r / min for 8 min at room temperature, Remove the solid in the lower layer, wash it with deionized water for 5 times, place it in an oven at 80° C. and dry it for 4 hours to obtain ultrafine graphite powder with an average parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com