A kind of zero-valent iron disulfide heterogeneous Fenton system and method thereof

A disulfide and sulfide technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of loss of catalytic activity, large energy consumption, waste of resources, etc., and achieve reduction of disulfide Secondary pollution, improving economic benefits, and reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

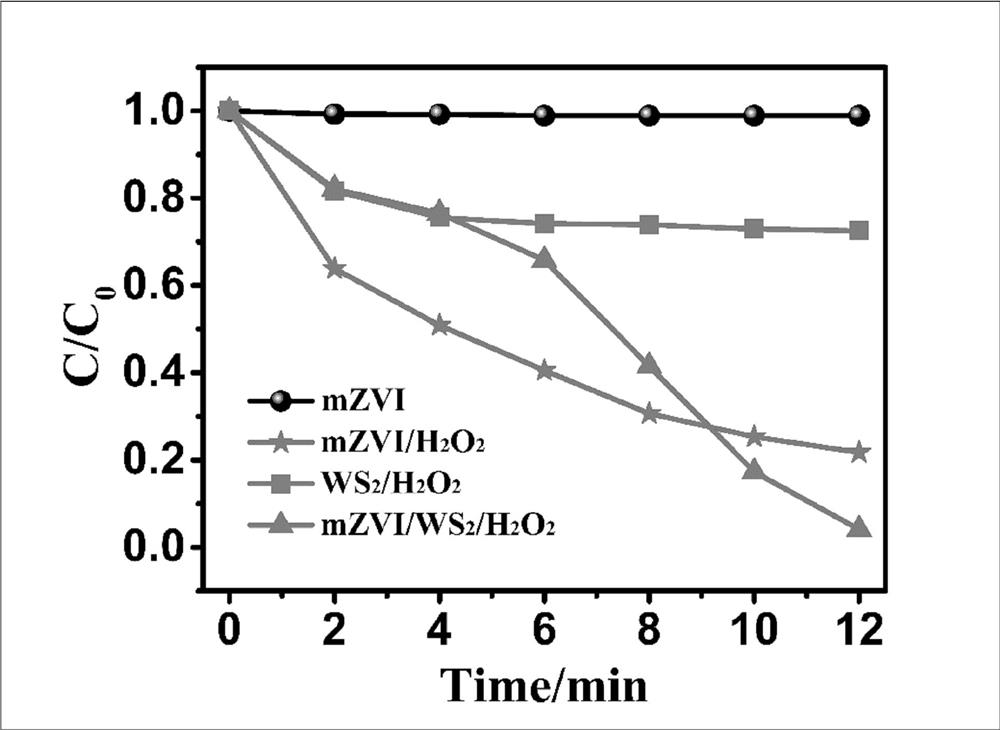

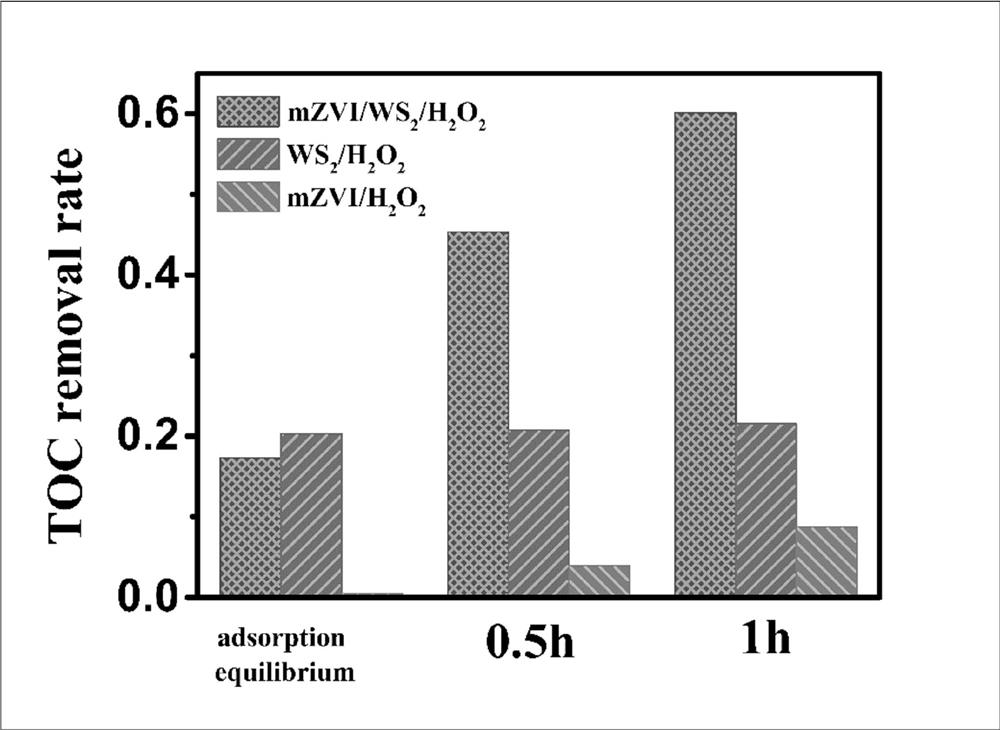

[0063] Embodiment 1: A heterogeneous Fenton system of zero-valent iron disulfide, the heterogeneous Fenton system is a liquid containing suspended particles of zero-valent iron and dissolved in disulfide, and the zero-valent iron in the liquid The concentration is 100~500mg / L, and the disulfide concentration of the liquid is 0.3~1g / L.

[0064] Wherein, the zero-valent iron is one or more of reduced iron powder, millimeter iron element, nano-iron powder or nano-iron element.

[0065] Wherein, the disulfide is one or more of tungsten disulfide and / or molybdenum disulfide.

Embodiment 2

[0066] Embodiment 2: A construction method of a zero-valent iron disulfide heterogeneous Fenton system, comprising the following steps:

[0067] S1, adding 30~100 parts by weight of disulfide to 100*10 3 In the solution to be treated in parts by weight, ultrasonic mixing is used to achieve full dispersion, and continuous stirring is used to achieve adsorption and desorption equilibrium;

[0068] S2, adjust the pH value to 3~5;

[0069] S3, adding 10 to 50 parts by weight of zero-valent iron and magnetic stirring to obtain a uniformly mixed zero-valent iron disulfide system.

[0070] Wherein, the zero-valent iron is one or more of reduced iron powder, millimeter iron element, nano-iron powder or nano-iron element.

[0071] Wherein, the disulfide is one or more of tungsten disulfide and / or molybdenum disulfide.

[0072] Wherein, the ultrasonic mixing time in S1 is 5-20 minutes, preferably 10 minutes, subject to achieving sufficient dispersion;

[0073] Wherein, the continuou...

Embodiment 3

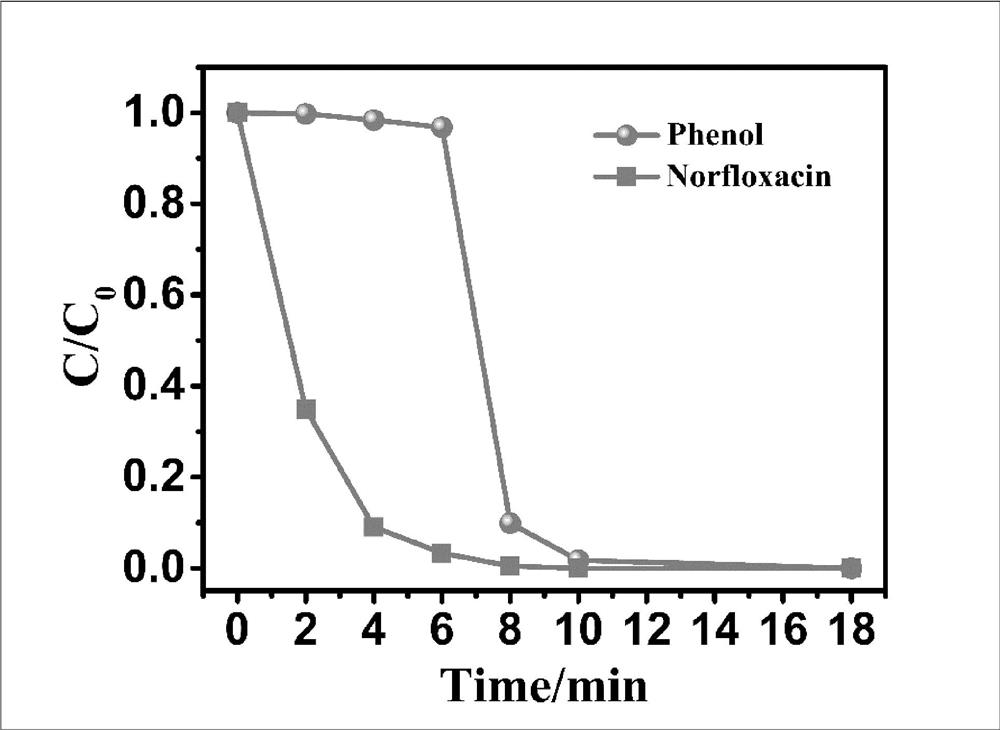

[0076] Embodiment 3: a kind of method of applying zero-valent iron disulfide to step-by-step treatment of waste water containing heavy metal ions and organic pollutants, comprising the following steps:

[0077] Step 1, the waste water containing heavy metal ions and organic pollutants is subjected to vacuum deoxygenation and nitrogen filling treatment to form deoxygenated waste water;

[0078] Step 2, adjust the pH value to 6~7;

[0079] Step 3: Add zero-valent iron in an atmosphere protected by nitrogen, stir evenly with magnetic force, and continue the reaction until the heavy metal ion treatment and precipitation are completed;

[0080] Step 4, separating the wastewater to obtain sediment and heavy metal ion-removed wastewater, adding disulfide to the heavy metal-ion-removed wastewater, ultrasonic mixing to achieve sufficient dispersion, and continuous mechanical stirring to achieve adsorption and desorption equilibrium;

[0081] Step 5, extracting zero-valent iron from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com