A kind of one-component root puncture resistant waterproof coating and preparation method thereof

A waterproof coating and root puncture-resistant technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of unsatisfactory tensile strength, bond strength, and elongation at break, roof eradication, and expensive repairs Restructuring cost, no root puncture resistance and other problems, to achieve the effect of enhanced waterproof effect, excellent root resistance performance, and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

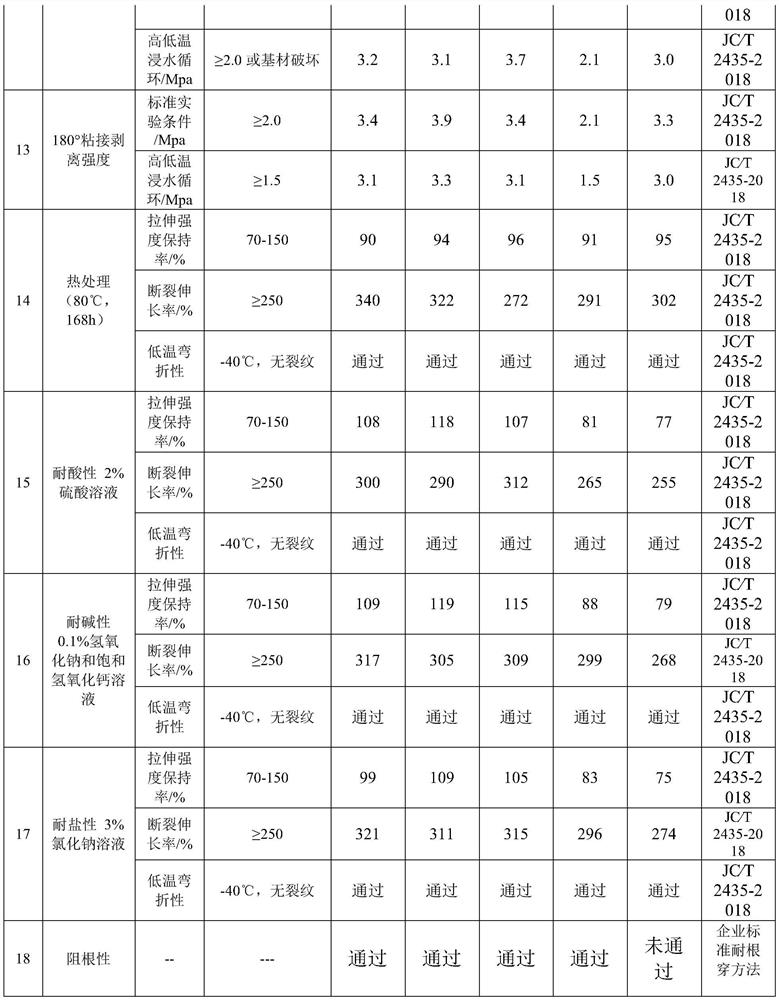

Examples

Embodiment 1

[0039] This example provides a one-component root puncture-resistant waterproof coating. The raw materials include: 7 parts of TDI80, 15 parts of polyether 330N, 15 parts of polyether 1000, 0.5 parts of γ-aminopropyltriethoxysilane, surface amination 1 part of boron nitride, 2 parts of clearlink1000, 3 parts of latent curing agent 401, 30 parts of filler (50% of heavy calcium and talcum powder), 15 parts of DINP, 0.1 part of dibutyltin dilaurate.

[0040] Its preparation method comprises the following steps: dehydrating surface aminated boron nitride, polyether 330N and polyether 1000 in vacuum at 120°C and -0.1Mpa until the moisture content is lower than 0.05%, and then adding γ-aminopropyl triethyl Oxy-silicon and TDI80, react at 80°C for 3 hours, then add clearlink 1000 for chain extension reaction, react for 1.5 hours, titrate with NCO until the NCO content is 2.5%, stop the reaction, make a prepolymer, and then add it for drying and dehydration The filler and the remainin...

Embodiment 2

[0042] This example provides a one-component root puncture-resistant waterproof coating, and its raw materials include: 10 parts of MDI, 20 parts of polyether 330N, 0.5 parts of γ-aminopropyltrimethoxysilane, 1.5 parts of surface aminated boron nitride, clearlink 1 part of 3000, 3.5 parts of latent curing agent 401, 40 parts of filler (50% of heavy calcium and talcum powder), 10 parts of DINP, 0.5 part of dibutyltin dilaurate.

[0043] The preparation method includes the following steps: vacuum dehydrate the surface aminated boron nitride and polyether 330N at 120°C and -0.1Mpa until the moisture content is lower than 0.05%, and then add γ-aminopropyl trimethoxy silicon and MDI , reacted at 80°C for 3 hours, then added clearlink 3000 for chain extension reaction, reacted for 1.5 hours, titrated with NCO until the NCO content was 2.8%, stopped the reaction, made a prepolymer, and then added the dried and dehydrated filler and the remaining raw materials , mixed to make the one-...

Embodiment 3

[0045] This example provides a one-component root puncture-resistant waterproof coating. The raw materials include: 9 parts of TDI80, 10 parts of polyether 2000, 18 parts of polyether 1000, 0.8 parts of γ-aminopropyltriethoxysilane, surface hydroxylation 2 parts of boron nitride, 1.5 parts of jefflink7544, 3 parts of latent curing agent 401, 35 parts of filler (50% of heavy calcium and talcum powder), 8 parts of DINP, 0.3 parts of dibutyltin dilaurate.

[0046] The preparation method comprises the following steps: vacuum dehydrating surface hydroxylated boron nitride, polyether 2000 and polyether 1000 at 120°C and -0.1Mpa until the moisture content is lower than 0.05%, and then adding γ-aminopropyl triethyl Oxy-silicon and TDI80, react at 80°C for 3 hours, then add jefflink754 for chain extension reaction, react for 1.5 hours, titrate with NCO until the NCO content is 3.2%, stop the reaction, make a prepolymer, and then add drying and dehydration The filler and the remaining r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com