A kind of Lactobacillus plantarum qr19 and its application

A Lactobacillus plantarum, QR19 technology, applied in bacteria, microorganisms, microorganisms and other directions, can solve the problems of no reports of SOD formation, and achieve the effect of improving the brewing quality of soy sauce, unique acid-producing ability, and ensuring flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a preparation method of Lactobacillus plantarum QR19, the specific method is as follows:

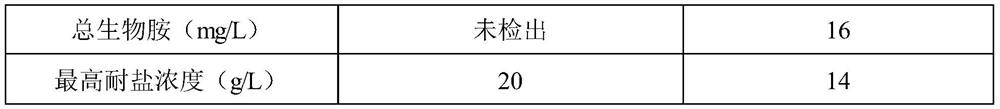

[0028] Lactobacillus plantarum QR19 is a mutant strain obtained from CICC 22703 by ARTP mutagenesis. The starting strain CICC No.22703 has weak salt tolerance and grows slowly at 16% salinity. In order to strengthen the specific preparation process, CICC No.22703 (purchased from China Industrial Microbiology Collection Center) was diluted to 10 8 1 / mL was irradiated by ARTP for 110s~130s, and then coated with MRS solid medium (casein peptone 10g / L, beef extract 10g / L, yeast powder 5.0g / L, glucose 5g / L, sodium acetate 5g / L , diamine citrate 2g / L, Tween 801g / L, dipotassium hydrogen phosphate 2g / L, magnesium sulfate heptahydrate 0.2g / L, manganese sulfate heptahydrate 0.05g / L, calcium carbonate 20g / L, agar powder 20g / L). After cultivating for 5 days, pick out the strains with larger colonies to MRS solid medium with 12% salinity. After another 5 day...

Embodiment 2

[0033] This example provides a case of compound inoculation of Lactobacillus plantarum QR19 and Zygosaccharomyces rouckeri S96. The inoculation method is: Inoculate Lactobacillus plantarum QR19 during the koji making process, and inoculate Zygosaccharomyces rouckeri into the moromi in the fermenter S96, constant temperature fermentation, the specific steps are as follows:

[0034] Step 1, preparation of Lactobacillus plantarum QR19 and Zygomyces rouckeri S96 seed liquid:

[0035](1) Experimental strains: Lactobacillus plantarum QR19 provided in Example 1, Zygomyces rouckeri S96 provided by the patent (name: a Zygomyces rouckeri S96 and its application, application number: 2018111838542). Lactobacillus plantarum QR19 and Zygosaccharomyces rouckeri S96 strains were inoculated into the seed medium for expansion respectively from the slant; for the preparation method of Zygosaccharomyces rouckeri S96 strains, please refer to the patent: A Zygosaccharomyces rouckeri S96 and its app...

Embodiment 3

[0049] This embodiment provides a case of compound inoculation of Lactobacillus plantarum QR19 and Zygomyces rouckeri S96. The inoculation method is: inoculate Lactobacillus plantarum QR19 into the moromi mash on the first day in the fermenter, and inoculate Lactobacillus plantarum QR19 into the moromi mash on the 7th day in the fermenter tank. Zygomyces saccharomyces S96, fermented at constant temperature, the specific steps are as follows:

[0050] Step 1, preparation of Lactobacillus plantarum QR19 and Zygomyces rouckeri S96 seed liquid:

[0051] (1) Experimental strains: Lactobacillus plantarum QR19 provided in Example 1, Zygomyces rouckeri S96 provided by the patent (name: a Zygomyces rouckeri S96 and its application, application number: 2018111838542). Lactobacillus plantarum QR19 and Zygosaccharomyces rouckeri S96 strains were inoculated into the seed medium for expansion respectively from the slant; for the preparation method of Zygosaccharomyces rouckeri S96 strains, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com