Binary transition metal oxide and graphene oxide composite material, preparation method thereof and sodium ion battery

A technology of transition metals and composite materials, applied in secondary batteries, nanotechnology for materials and surface science, battery electrodes, etc., can solve problems such as unsatisfactory cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example is to prepare FeCoO x Specific examples of Product 1 of electrode materials.

[0046] Add 3 mmol of cobalt nitrate hexahydrate into 50 mL of deionized water and sonicate for 30 min until uniformly mixed to obtain the first product 1;

[0047] Then add 4.5mmol of sodium citrate and 2mmol of potassium ferricyanide to the first product 1 in sequence, and ultrasonicate for 30min until the mixture is homogeneous. After 3 times of deionized filtration and washing, the soaking time was 1 hour each time, and freeze-dried at -30°C for 12 hours, the second product 1 was obtained, which was the iron-cobalt Prussian blue analogue;

[0048] After grinding the obtained second product 1, the second product 1 was heated to 500°C at 2°C / min in a tube furnace with nitrogen gas, kept for 5 hours for heat treatment, and product 1 was obtained after cooling, namely FeCoO x Material.

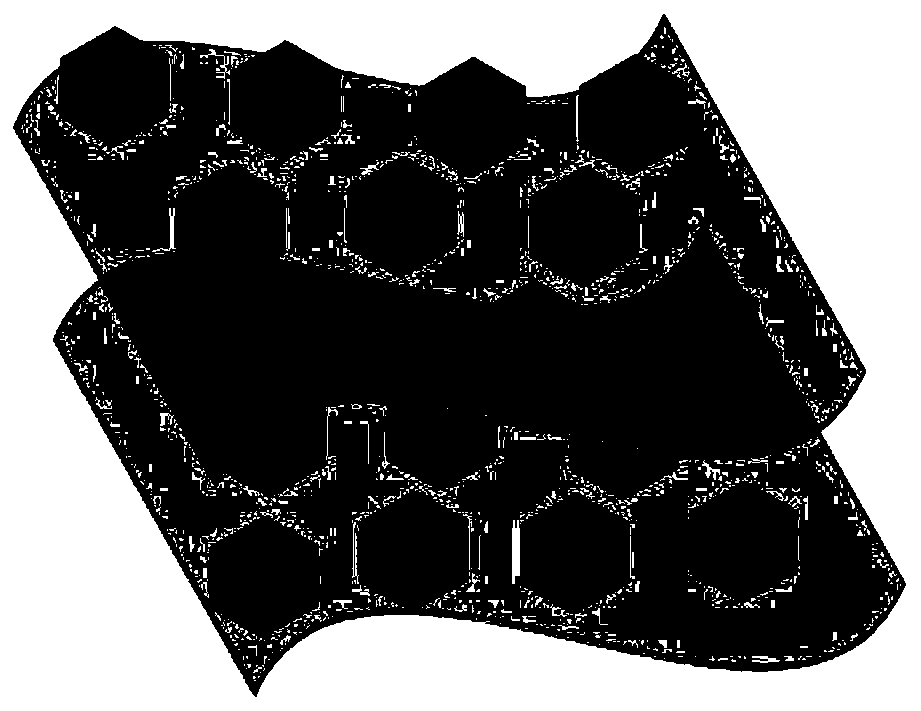

[0049] figure 2 For this example FeCoO x Scanning electron microscope images, such as ...

Embodiment 2

[0051] This example is to prepare FeCoO x A specific example of product 2 of graphene oxide (GO) composite electrode material.

[0052] Mix 3 mmol of cobalt nitrate hexahydrate and 1 mg / mL of graphene oxide dispersion to obtain the first product 2;

[0053] Add deionized water to the first product 2 to 50mL, sonicate for 30min until mixed evenly, then add 4.5mmol sodium citrate and 2mmol potassium ferricyanide in turn, sonicate for 30min until mixed evenly, after hydrothermal reaction at 120°C for 12h , the obtained product was soaked and washed in deionized water for 3 times, the soaking time was 1h each time, and after freeze-drying at -30°C for 12h, the second product 2 was obtained, that is, the iron-cobalt Prussian blue analogue / GO composite material, in which the iron-cobalt The particle size of the Prussian blue analogue is 60-150nm;

[0054] After grinding the obtained second product 2, the second product 2 was heated to 500°C at 2°C / min in a tube furnace with nitrog...

Embodiment 3

[0056] This example is to prepare FeCoO x A specific example of product 3 of the / GO composite electrode material.

[0057] 3mmol of cobalt nitrate hexahydrate and 2mg / mL of graphene oxide dispersion were mixed to obtain the first product 3;

[0058] Add deionized water to the first product 3 to 50mL, sonicate for 30min until mixed evenly, then add 4.5mmol sodium citrate and 2mmol potassium ferricyanide in turn, sonicate for 30min until mixed evenly, after hydrothermal reaction at 120°C for 12h , the obtained second product 3 was soaked and washed in deionized water three times, the soaking time was 1 hour each time, and freeze-dried at -30°C for 12 hours to obtain the second product 3, that is, the iron-cobalt Prussian blue analogue / GO composite material, Wherein the particle size of the iron-cobalt Prussian blue analogue is 60-150nm;

[0059] After grinding the obtained second product 3, the temperature of the second product 3 was raised to 500 °C at 2 °C / min in a tube fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com