Enzyme-loaded bacterial cellulose-based composite antibacterial hydrogel dressing and preparation method thereof

A bacterial cellulose and composite antibacterial technology, applied in the preparation and application of biomedical hydrogels, can solve the problems of ineffective killing of pathogenic bacteria, inconvenient use, poor moisture retention, etc., and achieve the effect of less drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

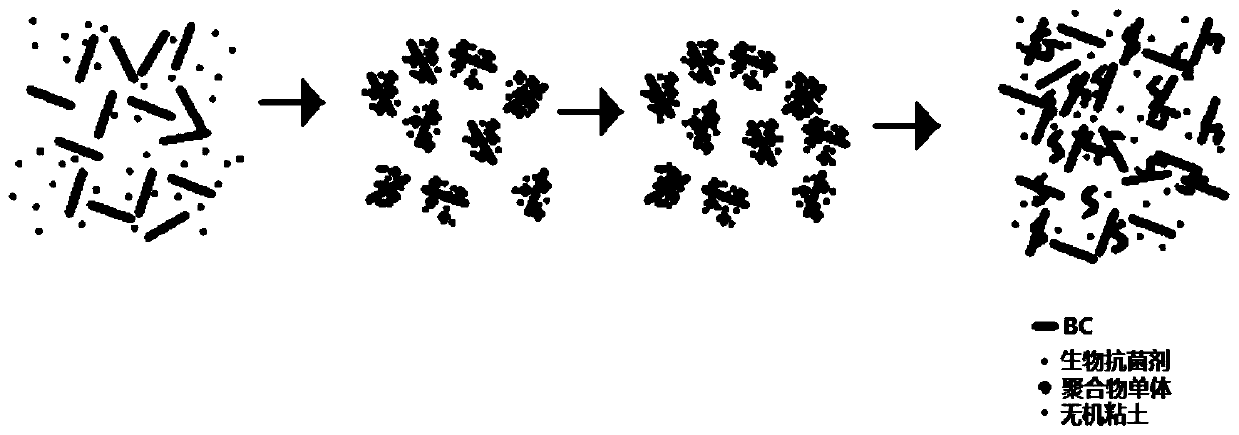

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the enzyme-loaded bacterial cellulose-based composite antibacterial hydrogel dressing of the present embodiment is as follows:

[0034] (1) Take the activated Acetobacter xylinum 1.1812 strain and inoculate it into the seed medium, culture it with shaking at 32°C for 24 hours, and the shaker speed is 150rpm. Then take out 10mL of cultured seeds and put them into 200mL sterilized fermentation medium (contained in a 500mL Erlenmeyer flask). Fully shake when inoculating to separate the strains and fully disperse them in the fermentation medium. Keep the temperature at 32°C. After static culture for 8 days, a BC hydrogel with a certain thickness was obtained. After the generated BCs were taken out, they were washed with deionized water several times to remove the culture medium and impurities on the membrane surface. Then soak the membrane in 1% NaOH solution, boil for 6 hours, remove the bacteria and residual culture medium in the liquid membrane...

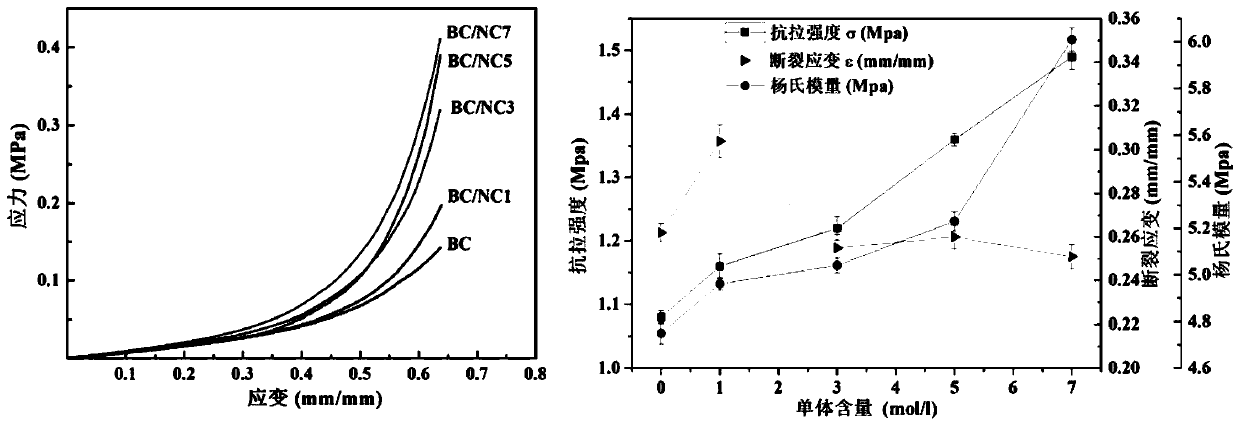

Embodiment 2

[0040] The preparation method of the enzyme-loaded bacterial cellulose-based composite antibacterial hydrogel dressing of the present embodiment is as follows:

[0041] (1) Take the activated Acetobacter xylinum 1.1812 strain and inoculate it into the seed medium, culture it with shaking at 32°C for 24 hours, and the shaker speed is 150rpm. Then take out 10mL of cultured seeds and put them into 200mL sterilized fermentation medium (contained in a 500mL Erlenmeyer flask). Fully shake when inoculating to separate the strains and fully disperse them in the fermentation medium. Keep the temperature at 32°C. Static culture for 8 days to obtain a BC film with a certain thickness. After the generated BCs were taken out, they were washed with deionized water several times to remove the culture medium and impurities on the membrane surface. Then soak the membrane in 1% NaOH solution, boil for 6 hours, remove the bacteria and residual culture medium in the liquid membrane, then rinse w...

Embodiment 3

[0047] The preparation method of the enzyme-loaded bacterial cellulose-based composite antibacterial hydrogel dressing of the present embodiment is as follows:

[0048] (1) Take the activated Acetobacter xylinum 1.1812 strain and inoculate it into the seed medium, culture it with shaking at 32°C for 24 hours, and the shaker speed is 150rpm. Then take out 10mL of cultured seeds and put them into 200mL sterilized fermentation medium (contained in a 500mL Erlenmeyer flask). Fully shake when inoculating to separate the strains and fully disperse them in the fermentation medium. Keep the temperature at 32°C. Static culture for 8 days to obtain a BC film with a certain thickness. After the generated BCs were taken out, they were washed with deionized water several times to remove the culture medium and impurities on the membrane surface. Then soak the membrane in 1% NaOH solution, boil for 6 hours, remove the bacteria and residual culture medium in the liquid membrane, then rinse w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com