A volatile organic compound adsorption and desorption treatment and resource recovery device

A volatile organic compound and resource recovery technology, applied in organic chemistry, gas treatment, adsorption purification/separation, etc., to achieve high heat exchange efficiency, avoid water scaling, and solve the effect of heat and cold alternation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

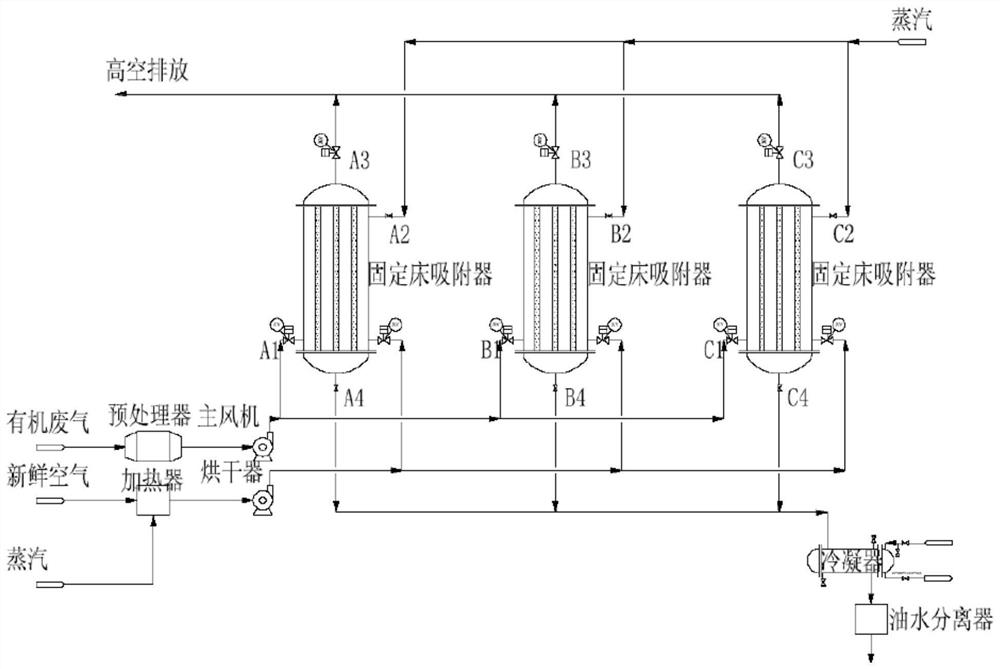

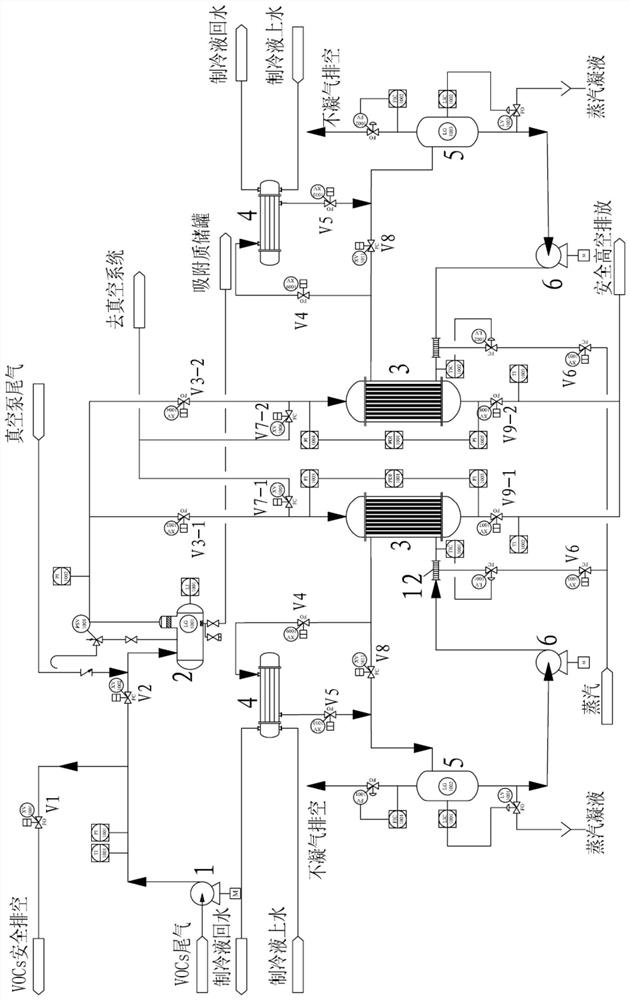

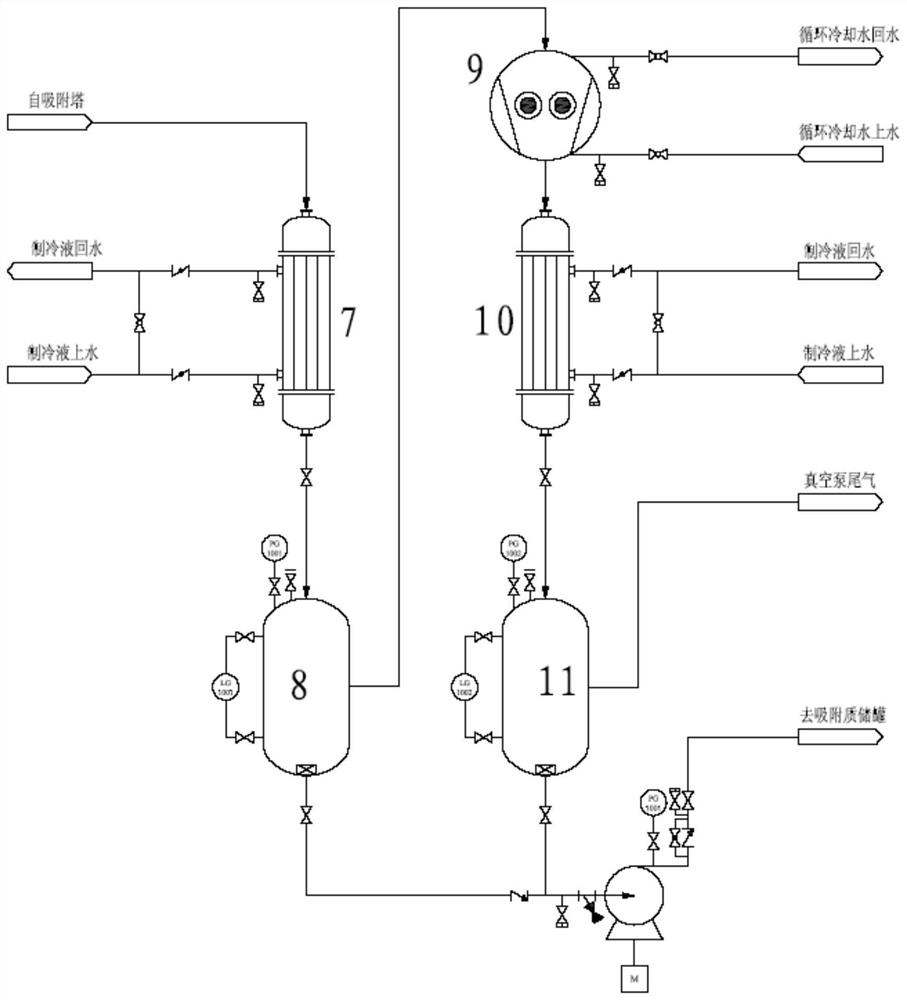

[0048] Such as figure 2 As shown, a volatile organic compound adsorption and desorption treatment and resource recovery device includes an adsorption and desorption unit, a water circulation unit and a vacuum unit; the adsorption and desorption unit includes an induced draft fan 1 and a VOCs waste gas buffer tank 2 With the two adsorbers 3; VOCs exhaust gas is also called VOCs exhaust gas, including organized exhaust gas and unorganized exhaust gas; the induced draft fan 1 can be a centrifugal fan, a Roots fan, etc., and the selection of the type belongs to common knowledge, and will not be repeated. VOCs exhaust gas is connected to the inlet of induced draft fan 1, and the outlet of induced draft fan 1 is connected to the inlet of VOCs exhaust gas buffer tank 2 through the second valve V2. The outlet of induced draft fan 1 is also connected in parallel to the safety exhaust pipeline through the first valve V1. When the system is operating normally, the second valve V2 is ope...

example 1

[0072] Example 1, if a styrene manufacturer discharges waste gas, the total concentration of styrene in the tail gas is 3.5×105mg / m 3 , the total amount of exhaust gas reaches 300m 3 / h. use as figure 2 and 3 Process scheme shown for processing. The styrene tail gas is led to the adsorption device by the fan. When the adsorption device is abnormal or in an emergency state, the shut-off valve is quickly switched to the emergency emptying to ensure the safety of the device. The exhaust gas introduced by the fan is sent to the buffer tank to remove the liquid and dust solids carried by the exhaust gas. The pretreated styrene tail gas enters the tubular fixed-bed adsorber, and is safely discharged at high altitude after treatment. The adsorbent is 3-6 mm silane-modified silicon dioxide and modified activated carbon pellets are packed in the fixed bed tubes at a ratio of 1:1 from top to bottom. The specification of the tubes is Φ38*3.5, and the ratio of the heat exchange are...

example 2

[0075] Example 2, if a hydrogen peroxide manufacturer discharges waste gas, the tail gas contains a variety of heavy aromatics, the content of which is as high as 4500ppm, and the total waste gas reaches 36000Nm 3 / h. use as figure 2 and 3 Process scheme shown for processing. The styrene tail gas is led to the adsorption device by the fan. When the adsorption device is abnormal or in an emergency state, the shut-off valve is quickly switched to the emergency emptying to ensure the safety of the device. The exhaust gas introduced by the fan is sent to the buffer tank to remove the liquid and dust solids carried by the exhaust gas. The pretreated tail gas enters the coiled radial fixed bed adsorber, and is safely discharged at high altitude after treatment. The adsorbent is 3-6mm silane-modified silicon dioxide and is packed in the shell side of the fixed bed. The specification of the tubes is Φ19*2, and the ratio of the heat exchange area of the adsorber to the loading ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com