Abrasive containing brush wire for rolled steel finishing production line and preparation method for abrasive containing brush wire

An abrasive brush and production line technology, applied in the field of steel rolling finishing, can solve the problems of brush wire temperature resistance and other problems, so as to avoid scratching the steel plate/strip, excellent grinding ability, excellent temperature resistance and fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An abrasive-containing brush filament for a steel rolling and finishing production line, which includes the following components in terms of mass percentage: nylon (nylon 66) 60%, thermoplastic resin (polyarylether Ketone) 20%, abrasive particles (silicon carbide with a particle size of 75 μm) 17%, coupling agent (silane coupling agent) 1%, anti-aging agent (ultraviolet absorber UV-P) 1%, antioxidant (antioxidant Agent 1098) 1%. The abrasive brush filament is prepared as follows:

[0028] Mix nylon 66 and polyarylether ketone and heat it to a molten state, then add silicon carbide with a particle size of 75 μm, silane coupling agent, ultraviolet absorber UV-P and antioxidant 1098, mix well and pass through the extruder Extrude and stretch to make silk.

Embodiment 2

[0030] An abrasive-containing brush wire used in a steel rolling finishing production line, the abrasive-containing brush wire includes the following components in terms of mass percentage: nylon (nylon 1010) 50%, thermoplastic resin (polyarylene sulfide) with a continuous use temperature > 150°C Ether) 25%, abrasive particles (silicon nitride with a particle size of 40 μm) 22%, coupling agent (titanate coupling agent) 1.5%, anti-aging agent (light stabilizer HPT) 0.75%, antioxidant (antioxidant Oxygen 1010) 0.75%. The abrasive brush filament is prepared as follows:

[0031] Mix nylon 1010 and polyarylene sulfide and heat to a molten state, then add silicon nitride with a particle size of 40 μm, titanate coupling agent, light stabilizer HPT and antioxidant 1010, mix well and pass through extrusion Machine extrusion, and stretching, made into silk, you can.

Embodiment 3

[0033] An abrasive-containing brush wire used in a steel rolling finishing production line, the abrasive-containing brush wire includes the following components in terms of mass percentage: 36% nylon (nylon 612), thermoplastic resin (polyether ether) with a continuous use temperature > 150°C ketone) 31%, abrasive particles (corundum with a particle size of 13 μm) 30%, coupling agent (titanate coupling agent) 2%, anti-aging agent (ultraviolet absorber UV-327) 0.5%, antioxidant (antioxidant Oxygen 1076) 0.5%. The abrasive brush filament is prepared as follows:

[0034] Mix nylon 612 and polyether ether ketone and heat it to a molten state, then add corundum with a particle size of 13 μm, titanate coupling agent, ultraviolet absorber UV-327 and antioxidant 1076, mix well and pass through extrusion Machine extrusion, and stretching, made into silk, you can.

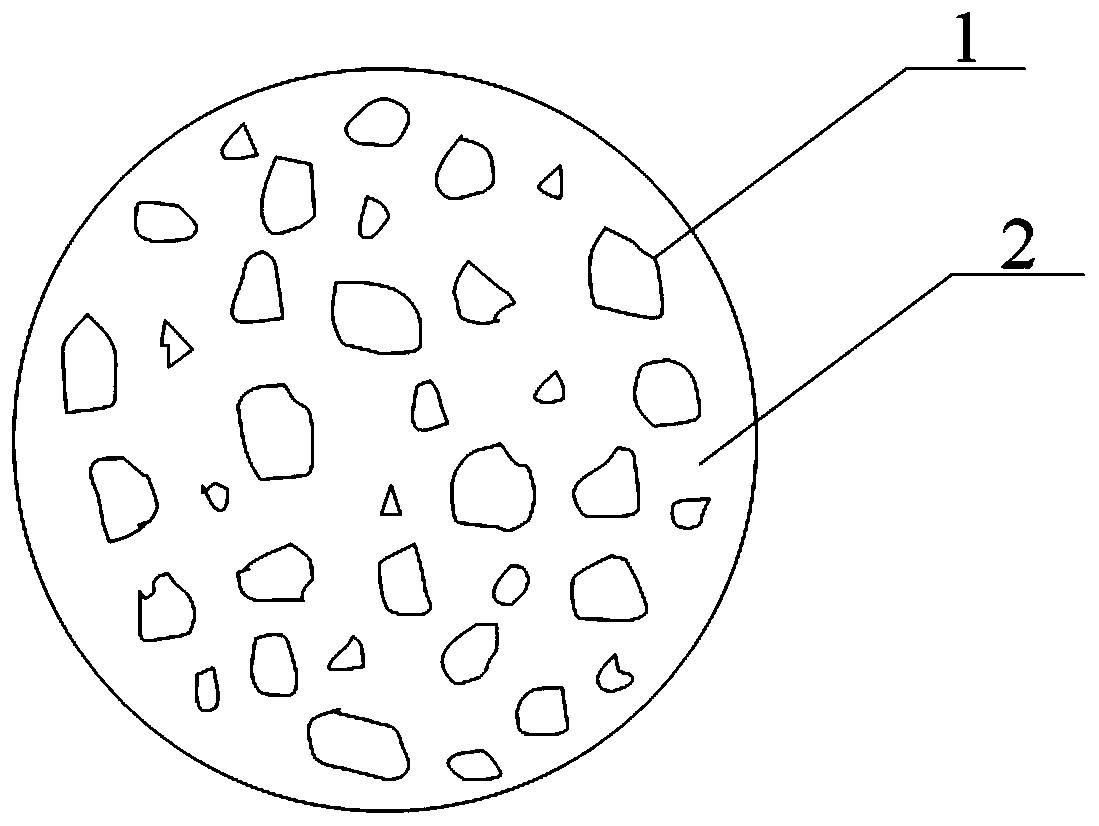

[0035] In the present invention, the schematic cross-sectional view of the abrasive brush filament is as follows: figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com