A kind of preparation method of flexible barium titanate ceramic nanofiber membrane

A nanofiber membrane, barium titanate technology, applied in the direction of inorganic raw material artificial filament, textile and papermaking, fabric surface trimming, etc., to achieve the effects of high low-frequency vibration sensitivity, low cost, and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Method for preparing flexible titanate ceramic nanofibers, specific steps:

[0033] (1) Formulated with a sol gel method: 0.3 g of polyvinylpyrrolidone (Aladdin, M) with a sol gel method: 0.3 g of polyvinylpyrrolidone (Aladdin, M) at 30 ° C w = 1,300,000) was stirred in 6 g of solvent (water, glacial acetic acid and mixture of glacial acetic acid and ethanol), and then 0.9 g of acetate and tetrabutyl acetate and titanate, stirred for 120min, mix well mix The phytosyl titanium titanium titanate, wherein the molar ratio of the tire and titanium elements in the solution is 1: 1;

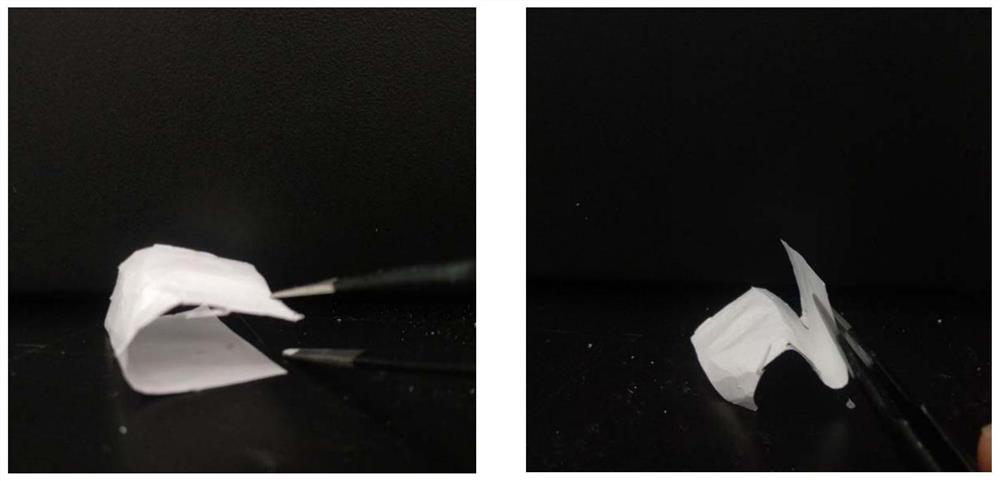

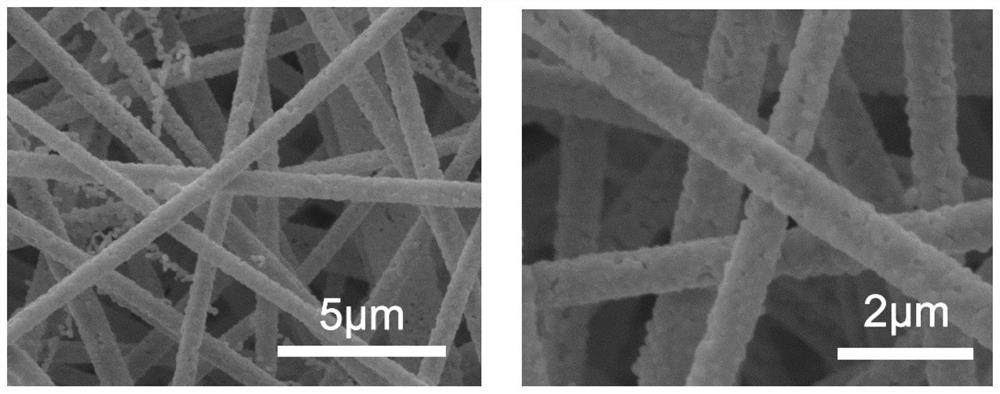

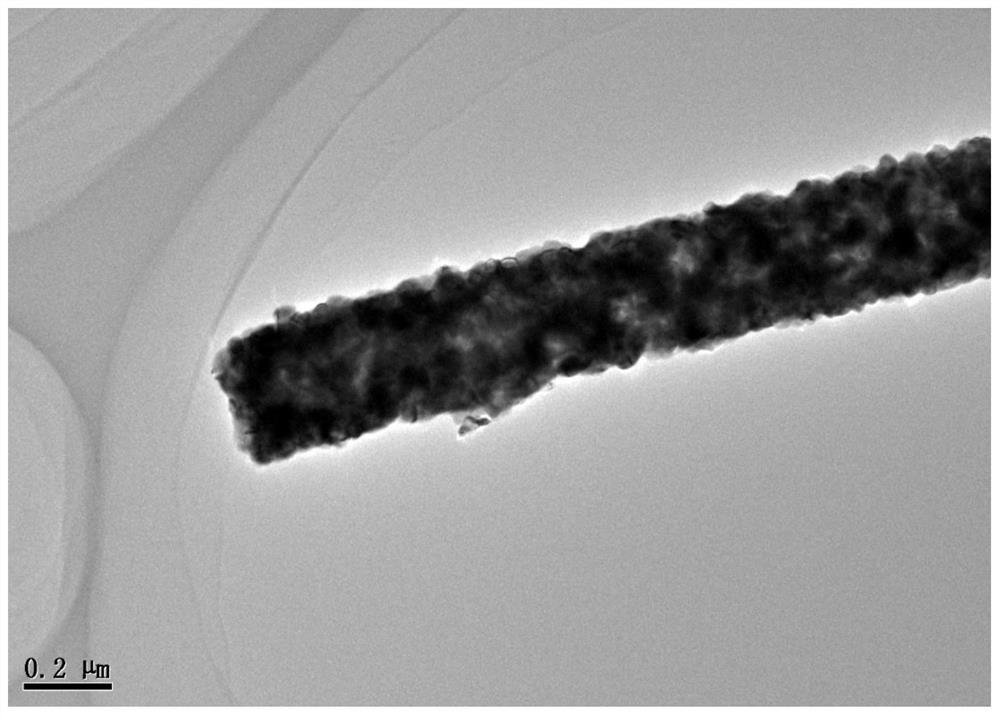

[0034] (2) The above titanate precursor sol is electrostatically spun, under an electric field, the charged droplets overcome the surface tension to form a jet and elongated in the air, and finally deposited on the receiving substrate, obtain a precursor nanofiber film. When electrostatic spinning, a constant temperature hot field of 25 ° C is applied to the spinning section and control the temperatu...

Embodiment 2

[0038] The present invention provides a method of preparing a flexible BTO ceramic nanofiber, and the preparation method is similar to that of Example 1, in which the polymer selects polyvinyl alcohol (Aladdin, M) in step (1). w = 600,000), and give a quantitative acetylacetone as a chelating agent, the specific steps are:

[0039] (1) Formulate the titanate precursor sol with sol gel method: 0.25 g of polyvinyl alcohol (Aladdin, M) at 30 ° C w= 600,000) The mixture was stirred in a 5.5 g of a solvent (mass ratio of 3: 2: 4: 2), and mixture of glacial acetic acid, ethanol and acetylacetone) was stirred, and then 0.9 g of acetate and tetrabutyl acetate and titanate. Stirring 120min, mix wellly mixed with barium titanate precursor sol, wherein the molar ratio of barium and titanium elements in the solution is 1: 1;

[0040] (2) The above titanate precursor sol is electrostatically spun, under an electric field, the charged droplets overcome the surface tension to form a jet and elon...

Embodiment 3

[0044] The present invention provides a method of preparing a flexible BTO ceramic nanofiber, and the preparation method is similar to that of Example 1, in which in step (1), the constructed sol - gel system is glacial acetic acid-n-but Alcohol, specific steps are:

[0045] (1) Formulated with a sol gel method: 0.3 g of polyvinylpyrrolidone (Aladdin, M) with a sol gel method: 0.3 g of polyvinylpyrrolidone (Aladdin, M) at 30 ° C w = 1,300,000) was stirred in a 5.4 g of a solvent (a mixture of glacial acetic acid and n-butanol with mass ratio of 4: 5), and then 0.9 g of acetate and tetrabutyl acetate and titanate, stirred for 120min, mix well mixed with titanium. Barium-borne precursor sol, wherein the molar ratio of barium and titanium elements in the solution is 1: 1;

[0046] (2) The above titanate precursor sol is electrostatically spun, under an electric field, the charged droplets overcome the surface tension to form a jet and elongated in the air, and finally deposited on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com