Application method of novel surfactant in zinc oxide ore flotation

A technology of surfactant and application method, applied in flotation, solid separation and other directions, can solve the problems of poor grade and recovery rate of zinc oxide concentrate, poor flotation effect of zinc oxide ore, poor solubility and dispersibility, etc. The value of promotion and application, the effect of strong action ability, and the effect of improving grade and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Application of 2-butyne-1,4-bis(hexadecylpiperidinyl ammonium bromide) in flotation of zinc oxide ore (flotation temperature: 25-28°C)

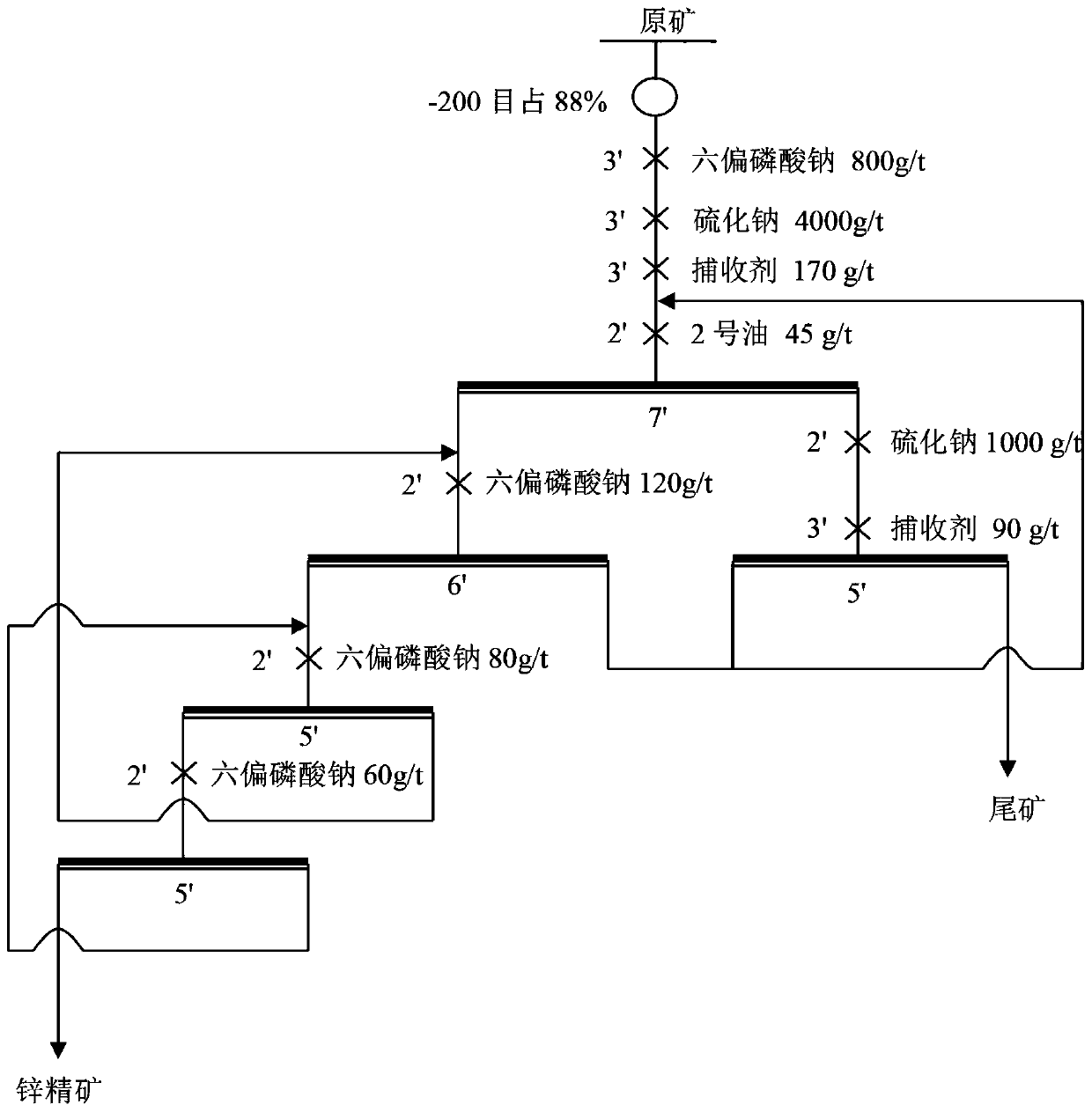

[0028] A zinc oxide mine in Yunnan, the ore contains 8.97% Zn, the ore is ground to -200 mesh to account for 88%, water is added to adjust the slurry to a mass concentration of 30%, and 800g / t sodium hexametaphosphate and 4000g / t sodium sulfide are added. 170g / t 2-butyne-1,4-bis(hexadecylpiperidinyl ammonium bromide), foaming agent No. 2 oil dosage 45g / t, carry out roughing flotation of zinc oxide ore, add 1000g by sweeping / t sodium sulfide, 90g / t 2-butyne-1,4-bis(hexadecyl piperidinyl ammonium bromide), add 120g / t sodium hexametaphosphate for the first selection, and add 120g / t sodium hexametaphosphate for the second selection Add 80g / t sodium hexametaphosphate, add 60g / t sodium hexametaphosphate for the third selection, adopt the flotation process of one roughing, one sweeping, three times of refining, the flotation pro...

Embodiment 2

[0034] Example 2: Application of new surfactants in flotation of smithsonite pure minerals (flotation temperature: 15-20°C)

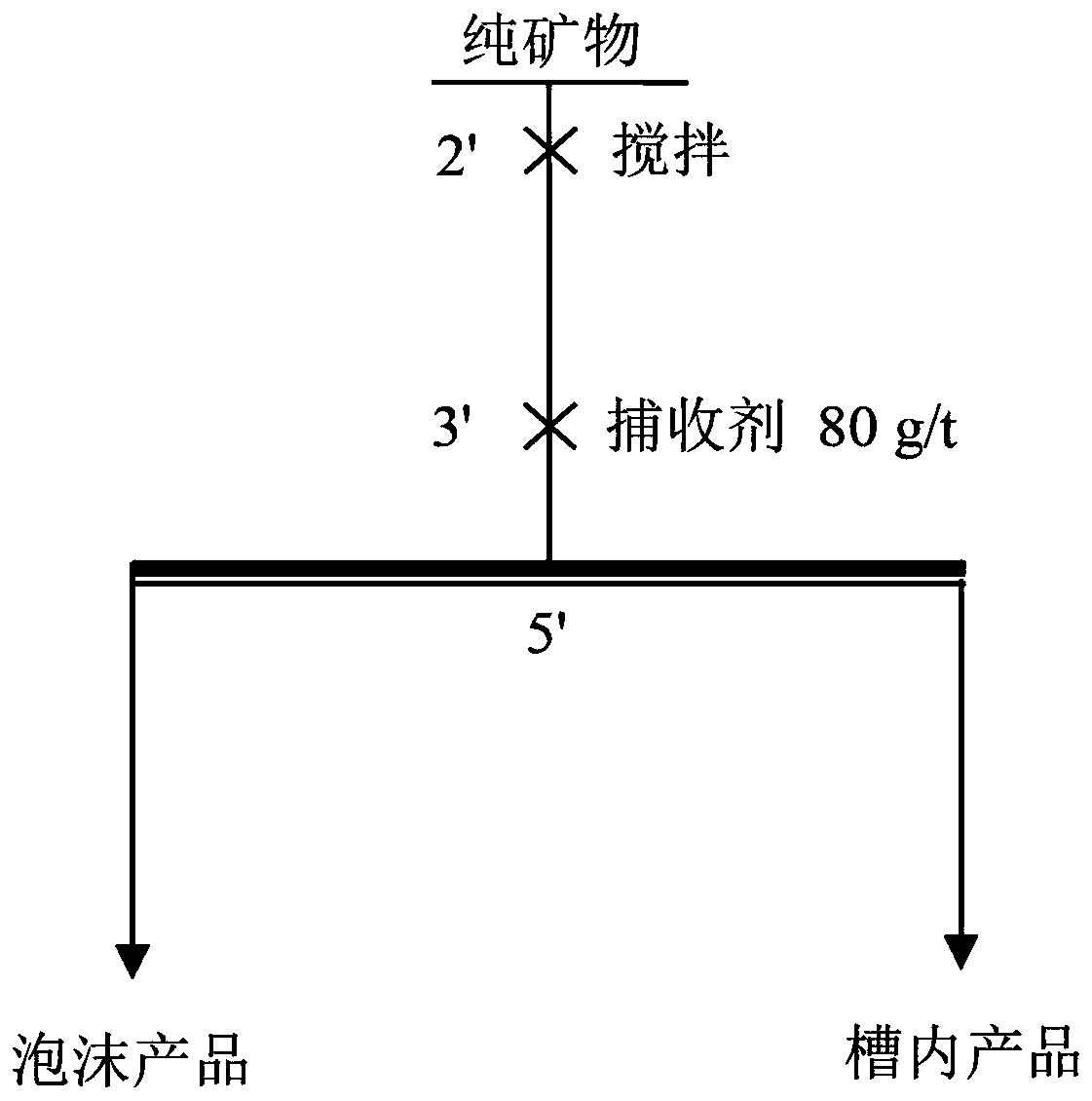

[0035] Put 2.0g of smithsonite pure mineral with a particle size of -0.15mm~+0.074mm into a 40mL flotation tank, add 30mL of distilled water, stir for 2min to make it evenly mixed, and carry out under the condition that the amount of collector is 80g / t Flotation, flotation process flow chart see attached figure 2 . Table 2 shows the flotation comparison test results of the novel collector among the present invention and two commonly used collectors, dodecylamine and hexadecylamine. It can be seen from Table 2 that the collection ability of the new collector for smithsonite is significantly stronger than that of the two commonly used aliphatic amine collectors.

[0036] Table 2 Comparative experimental results of collector flotation pure minerals

[0037]

Embodiment 3

[0038] Example 3: Application of 2-butyne-1,4-bis(hexadecylpiperidinyl ammonium bromide) in flotation of zinc oxide ore (flotation temperature: 15-20°C)

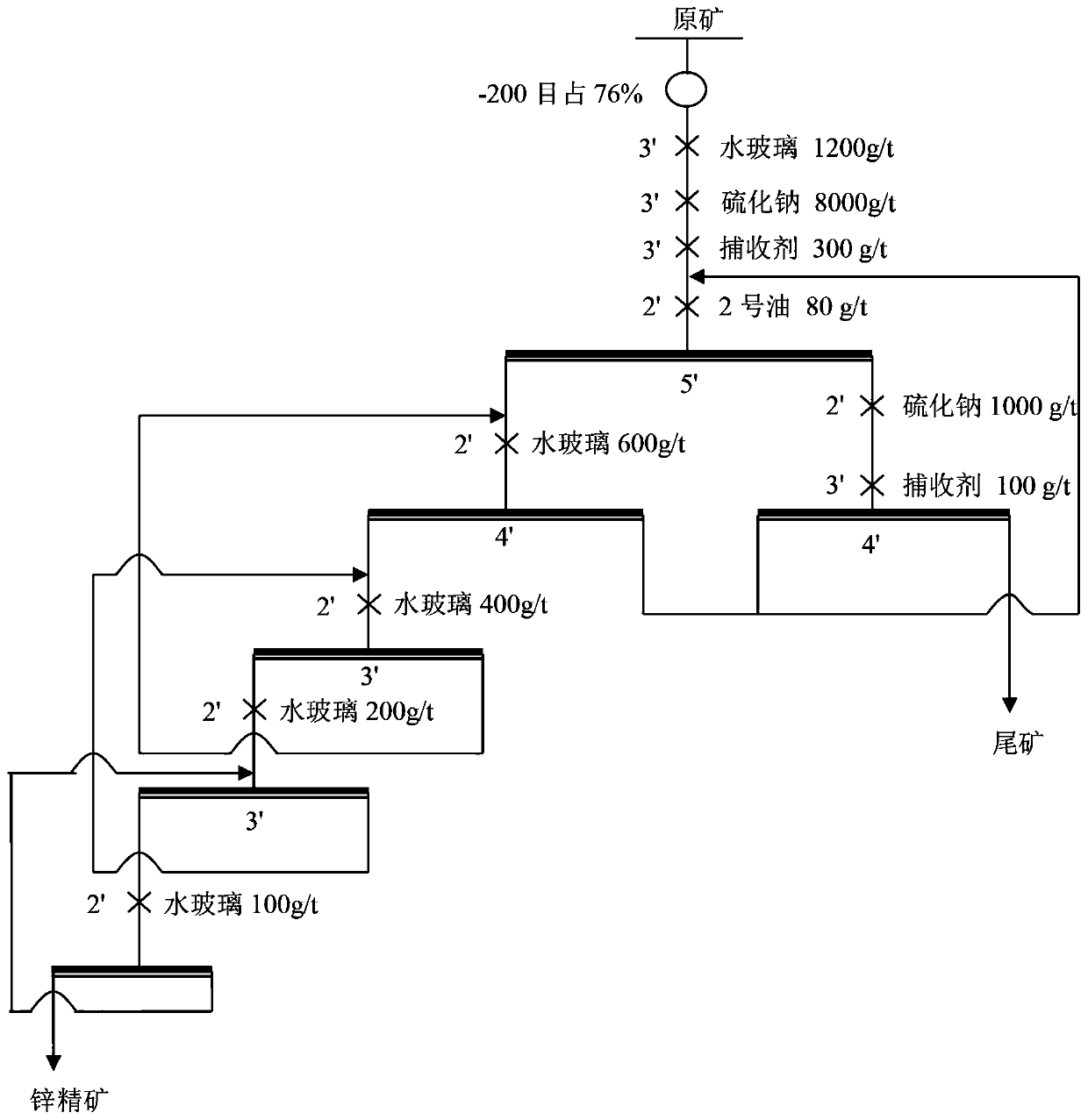

[0039] A low-grade zinc oxide ore sample, the original ore contains Zn6.12%, the ore is ground to -200 mesh to account for 76%, the concentration of the flotation pulp is 35%, the dosage of water glass is 1200g / t, and the dosage of sodium sulfide is 8000g / t. Under the conditions of 300g / t collector dosage and 80g / t foaming agent No. 2 oil dosage, roughing flotation of zinc oxide ore is carried out, 1000g / t sodium sulfide is added for sweeping, 100g / t collector is added, and once selected The amount of water glass is 600g / t, the amount of water glass added to the second selection is 400g / t, the amount of water glass added to the third selection is 200g / t, and the amount of water glass added to the fourth selection is 100g / t. The flow chart of the flotation process is attached. image 3. Table 3 shows the flotation comparis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com