Seaweed enzymolysis dry-powder added high-column compounded fertilizer and preparation method therefor

A high-tower compound fertilizer and enzymatic hydrolysis technology, which is applied in the direction of phosphate fertilizer, fertilization equipment, fertilizer mixture, etc., can solve the problems of not being developed and effectively used in large quantities, the destruction of macromolecular seaweed polysaccharides, and the inability to withstand high temperature and high pressure, etc., to achieve expansion Application range and use effect, small molecule, effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

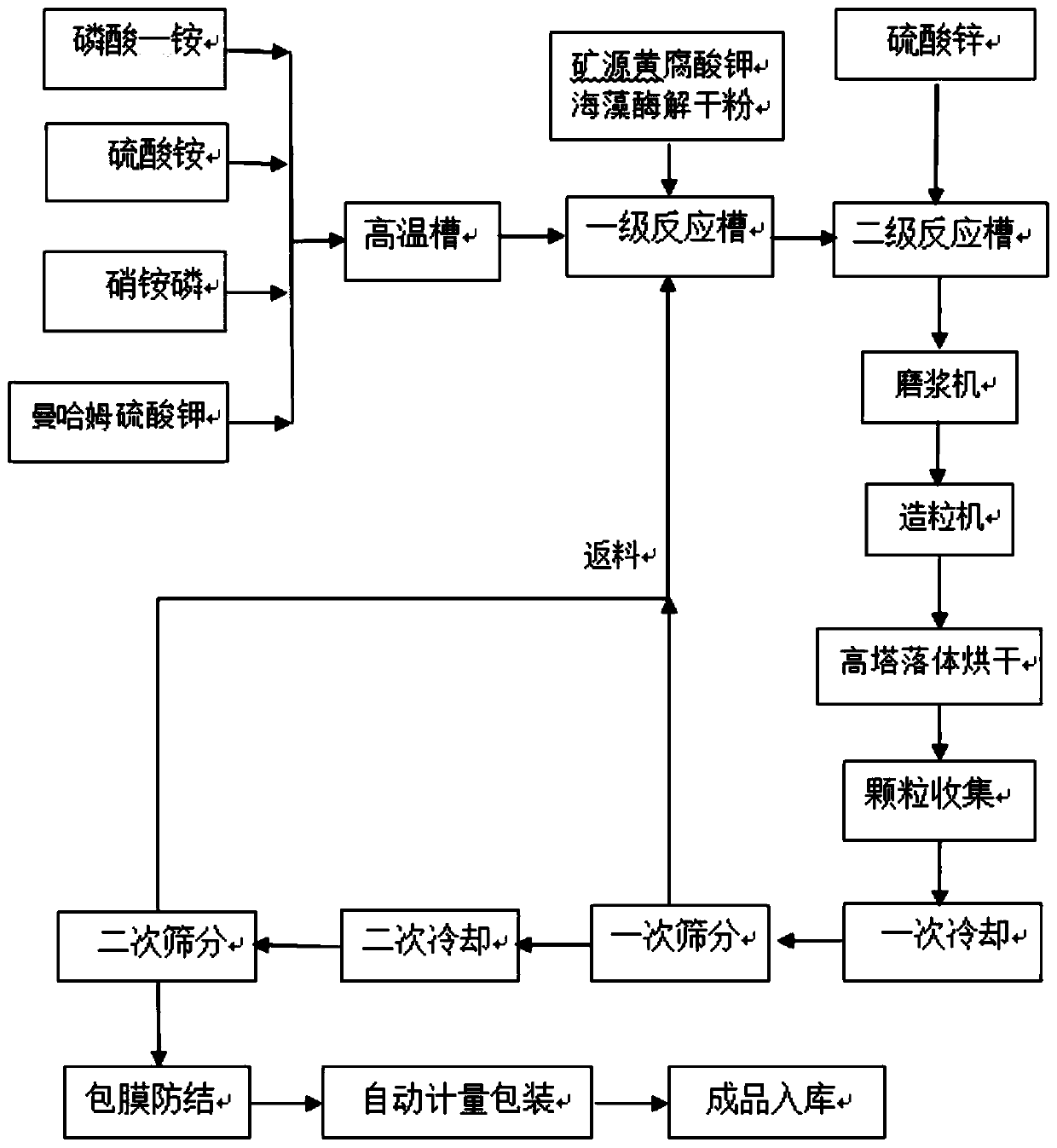

Method used

Image

Examples

Embodiment 1

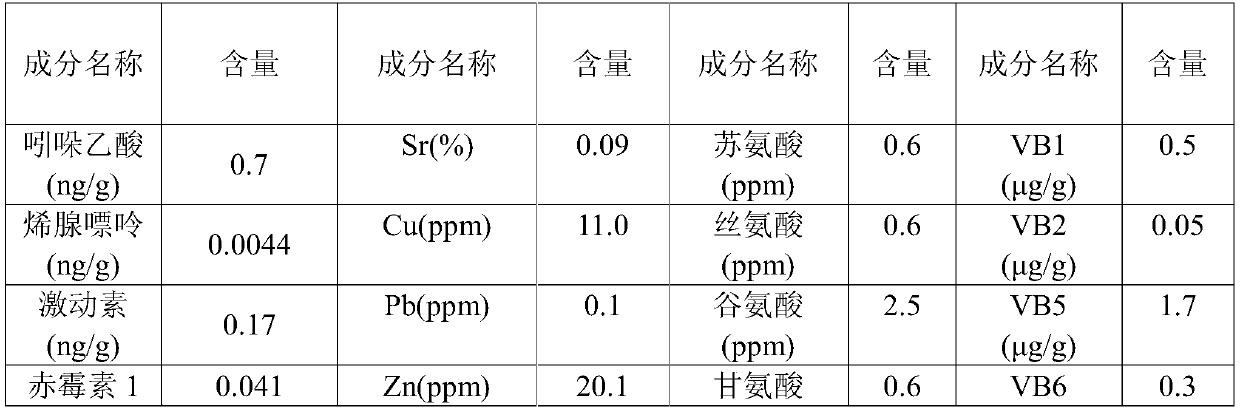

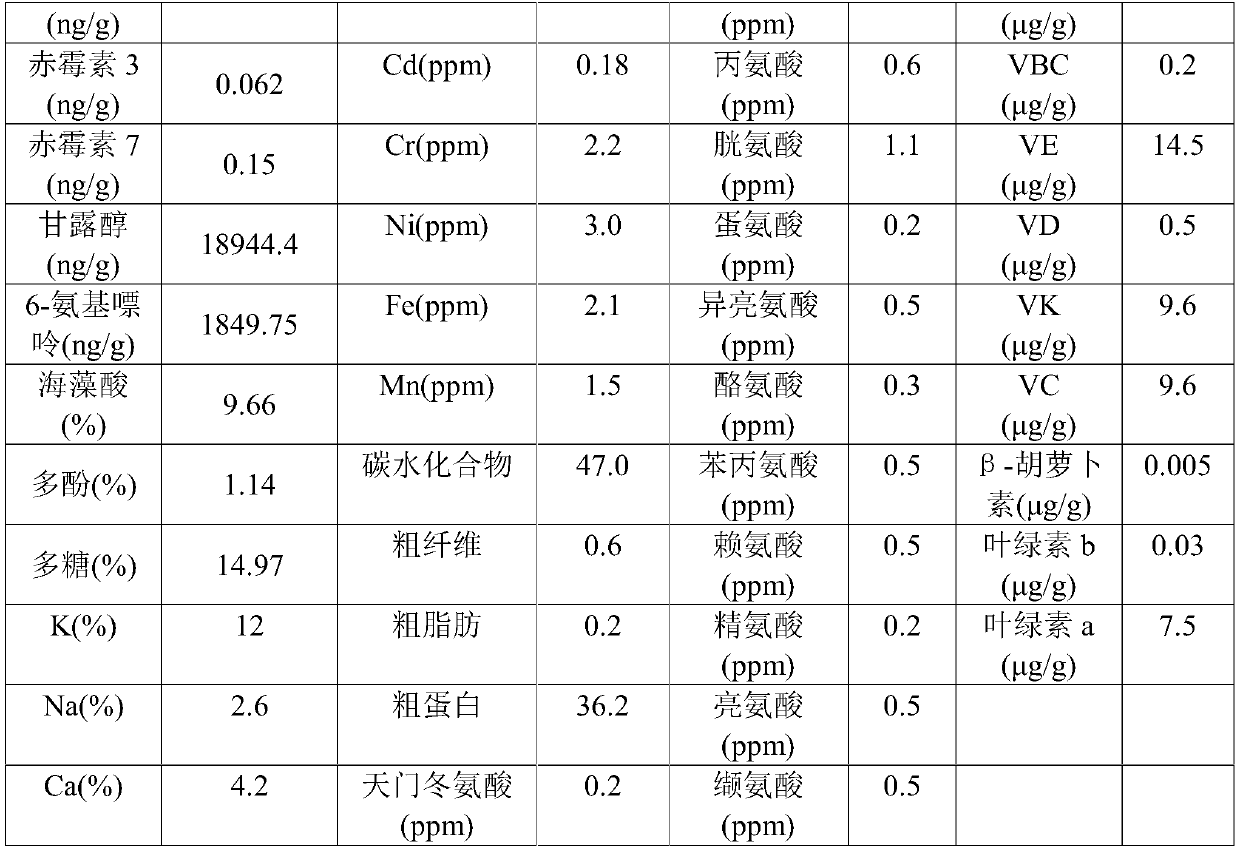

[0046] The high-tower compound fertilizer added with seaweed enzymolysis dry powder, the formula is as follows:

[0047] 60 kg of seaweed enzymatic hydrolysis dry powder; 230 kg of 72% monoammonium phosphate, 340 kg of 36% ammonium nitrate, 70 kg of 20.5% ammonium sulfate, 290 kg of 52% Manham potassium sulfate, 5 kg of mineral source potassium fulvic acid, 35 kg % Zinc sulfate monohydrate 5 kg.

[0048] Among them, the dry seaweed enzymatic hydrolysis powder is prepared by jointly enzymatically decomposing Ascophyllum nodosum with cellulase, pectinase and alginate lyase; in the seaweed enzymatic hydrolysis dry powder, the purity of alginic acid is ≥ 6.5%;

[0049] Ammonium nitrate is N32-P4, which is purchased from the market;

[0050] Manham potassium sulfate is K52, CI is less than 2%, purchased from the market;

[0051] Monoammonium phosphate is N12-P60, purchased from the market;

[0052] Ammonium sulfate is N20.5, purchased from the market;

[0053] Potassium fulvic ...

Embodiment 2

[0075] Seaweed enzymolysis dry powder, the preparation method is as follows:

[0076] Pretreatment: Dry the imported Ascophyllum nodosum from Northern Ireland, cut it at high speed, and then grind it into powder, soak the Ascophyllum nodosum powder in water to fully absorb water and swell;

[0077] Enzymolysis treatment: add cellulase, pectinase, and alginate lyase to the pretreated Ascophyllum nodosum powder in sequence, and perform enzymolysis at 42°C and pH 6.0 for 24 hours to obtain Ascophyllum nodosum enzymolysis solution; The amount of cellulase, pectinase and alginase lyase added is 3‰ of the total weight of the enzymolysis material; the dosage ratio of cellulase, pectinase and alginase is 1.1:0.9:1.

[0078] Post-processing: filter the Ascophyllum nodosum enzymatic solution to remove the residue, then adjust the filtrate to pH 7.2-7.5 with potassium carbonate, filter, continue to remove the precipitates such as calcium carbonate produced by the acid-base reaction, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com