A kind of high heat resistance and high crosslinking degree photocurable solder resist ink and preparation method thereof

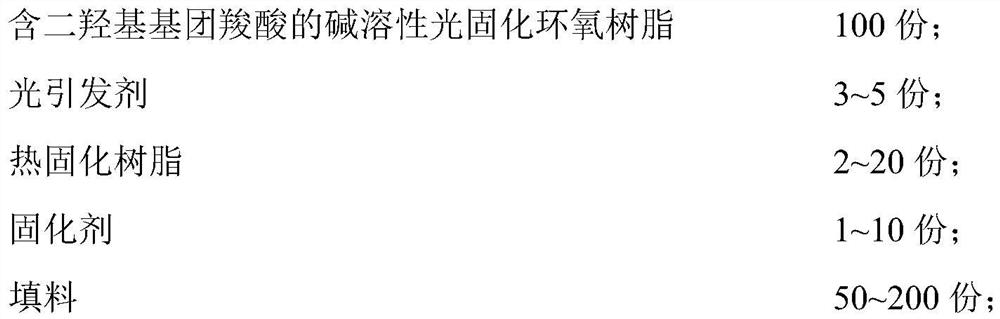

A technology of high cross-linking and solder resist ink, which is applied in the fields of high heat resistance and high cross-linking degree light-curing solder resist ink and its preparation, high cross-linking degree light-curing solder resist ink and its preparation field, which can solve the problem of changing the resistance of the system. Heat, uneven dispersion of the system, affecting product quality and other problems, to achieve the effect of improving product performance, reducing the amount of photoinitiator added, and reducing the impact of cured film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

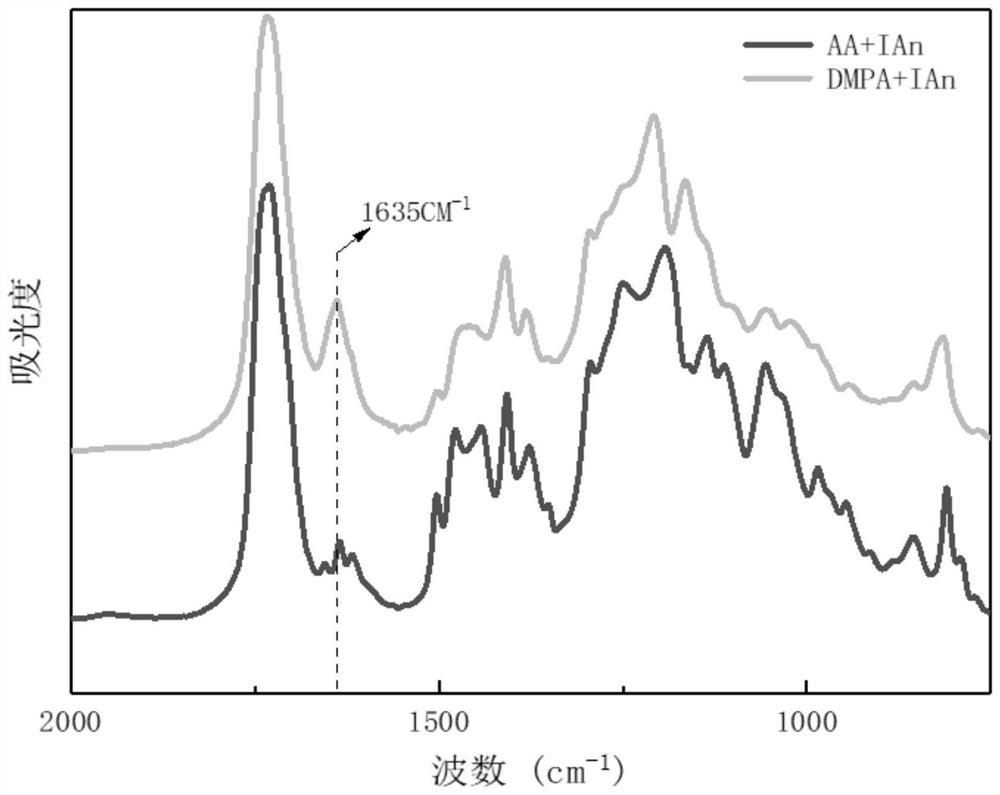

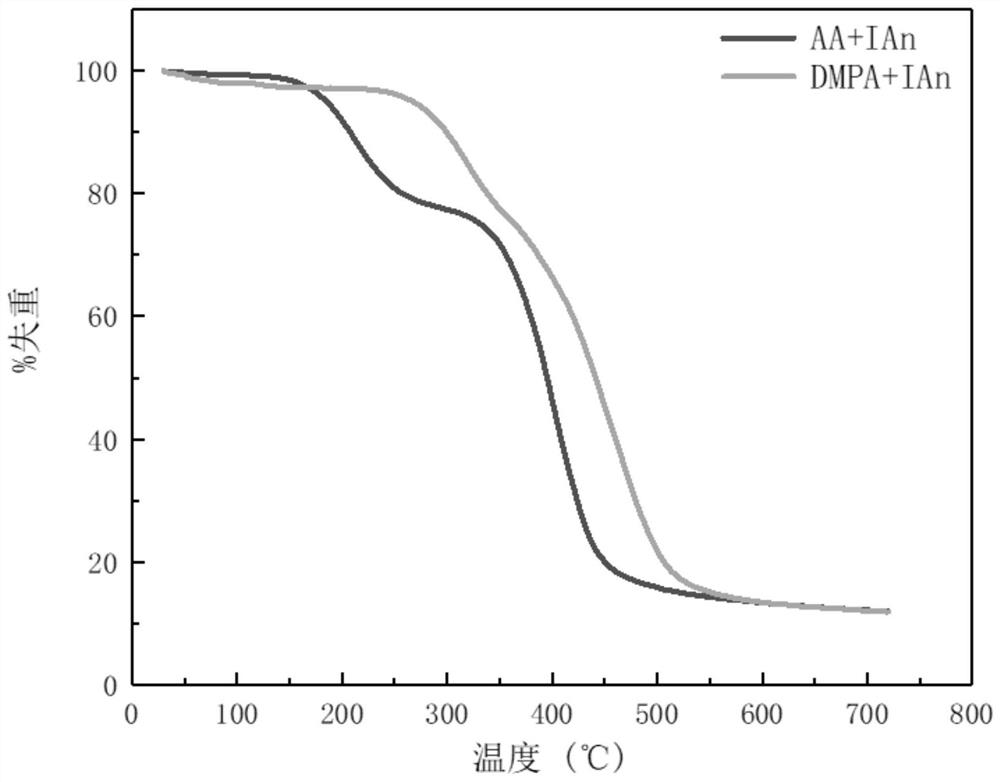

[0055] Under nitrogen protection, add 50.0g of diethylene glycol diethyl ether acetate (DCAC) into a 1L three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 88.8g of epoxy resin NPCN-704, and keep the temperature for one hour to fully Dissolve, cool down to 60°C and add 57.3g of 2,2-dimethylolpropionic acid (DMPA) dissolved in 40g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to carboxyl group is 1: 1), heat up to 70°C and then add 1.5g of catalyst 4-dimethylaminopyridine dissolved in 2g of diethylene glycol ethyl ether acetate, stir and react at a constant temperature of 95°C for 1 hour, then heat up to 105°C and stir at a constant temperature React for 12 hours. Then cool the reaction system to 80°C, add 94.0 g of itaconic anhydride dissolved in 30 g of diethylene glycol ethyl ether acetate (the molar ratio of carboxylic acid to anhydride is 1:2.1) and 0.5 g of hydroquinone as a polymerization inhibitor , the temperature...

Synthetic example 2

[0057] Under nitrogen protection, add 50.0g of diethylene glycol diethyl ether acetate (DCAC) into a 1L three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 88.8g of epoxy resin NPCN-704, and keep the temperature for one hour to fully Dissolve, cool down to 60°C and add 57.3g of 2,2-dimethylolpropionic acid (DMPA) dissolved in 40g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to carboxyl group is 1: 1), heat up to 70°C and then add 1.5g of catalyst 4-dimethylaminopyridine dissolved in 2g of diethylene glycol ethyl ether acetate, stir and react at a constant temperature of 95°C for 1 hour, then heat up to 105°C and stir at a constant temperature React for 12 hours. Then the reaction system was cooled to 80°C, and 82.2 g of maleic anhydride (MAH) dissolved in 30 g of diethylene glycol ether acetate (the molar ratio of carboxylic acid to anhydride was 1:2.1) and a pair of polymerization inhibitors were added. 0.5 g of hydroqu...

Synthetic example 3

[0059] Under nitrogen protection, add 50.0g of diethylene glycol diethyl ether acetate (DCAC) into a 1L three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 88.8g of epoxy resin NPCN-704, and keep the temperature for one hour to fully Dissolve, cool down to 60°C and add 63.3g of 2,2-dimethylolbutyric acid (DMBA) dissolved in 40g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to carboxyl group is 1: 1), heat up to 70°C and then add 1.5g of catalyst 4-dimethylaminopyridine dissolved in 2g of diethylene glycol ethyl ether acetate, stir and react at a constant temperature of 95°C for 1 hour, then heat up to 105°C and stir at a constant temperature React for 12 hours. Then cool the reaction system to 80°C, add 94.0 g of itaconic anhydride dissolved in 30 g of diethylene glycol ethyl ether acetate (the molar ratio of carboxylic acid to anhydride is 1:2.1) and 0.5 g of hydroquinone as a polymerization inhibitor , the temperature w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com