A preparation method of a shape-memory polymer material with drug release function, and the resulting product and application

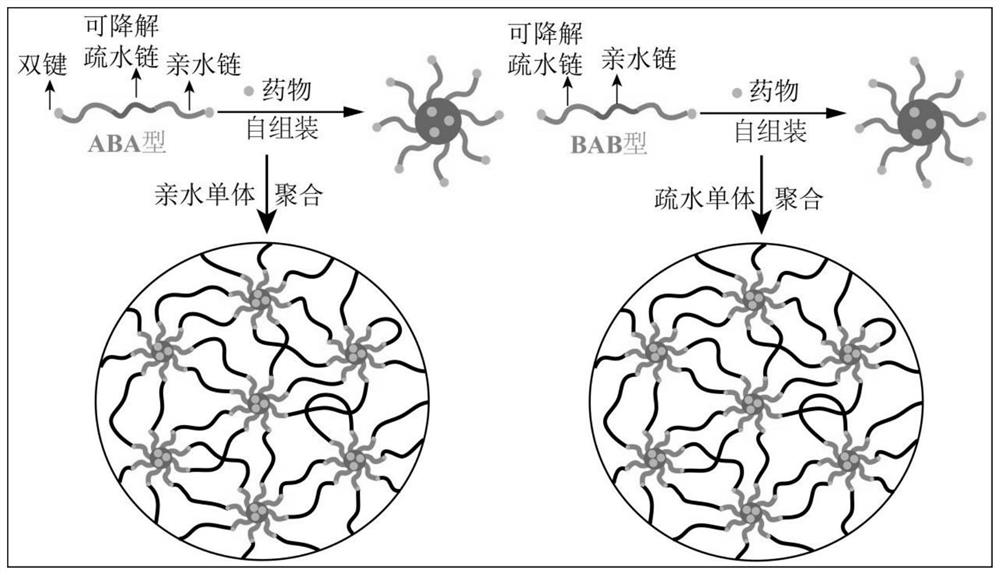

A technology of polymer materials and drugs, applied in the field of preparation of shape memory polymer materials, can solve the problems of mechanical strength and modulus decline, easy aggregation and precipitation of drugs, uncontrollable drug loading, etc., and achieve fast curing speed, stability and Sustained drug release effect, the effect of convenient control of the dissolved amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 1. Polyethylene glycol-polycaprolactone-polyethylene glycol triblock copolymer (PEG) functionalized with 152.45 mmol terminal acrylate groups 2500 -PCL 4000 -PEG 2500 ) and 0.1 g of enoxacin were dissolved in 18 ml of deionized water, and ultrasonically dispersed for 60 min, so that the triblock copolymer formed nanomicelles, and all the drugs were dissolved in the micelles.

[0073] 2. After completely dissolving, add 3.25g hydroxyethyl acrylate, 1.89g acrylic acid and 0.064g photoinitiator 2,2-dimethoxy-2-phenylacetophenone. Nitrogen gas was bubbled for 20 minutes to remove dissolved oxygen, and the mixed solution was slowly injected into the glass mold with a disposable syringe, and multiple molds injected with the reaction mixed solution were placed under an ultraviolet device for photocrosslinking reaction, wherein the ultraviolet light intensity was 10mW / cm 2 . Illuminate for 20 minutes before and after the mold. After the reaction is over, take the cross-lin...

Embodiment 2

[0083] 1, with embodiment 1.

[0084] 2. After it is completely dissolved, add 3.25g of hydroxyethyl acrylate, 1.89g of acrylic acid and 0.064g of potassium persulfate. Nitrogen gas was bubbled for 20 minutes to remove dissolved oxygen, and the mixed solution was slowly injected into glass molds with a disposable syringe, and multiple molds injected with the reaction mixed solution were placed in an oven, and reacted at a temperature of 45°C for 12 hours. After the reaction is over, the crosslinked polymer material is taken out from the mold and placed on a polytetrafluoroethylene film, dried in an oven at 60°C for 12 hours, and then the temperature is raised to 80°C for 12 hours in vacuum to obtain the described A shape-memory polymer material, which is a temperature-responsive or water-responsive shape-memory polymer material.

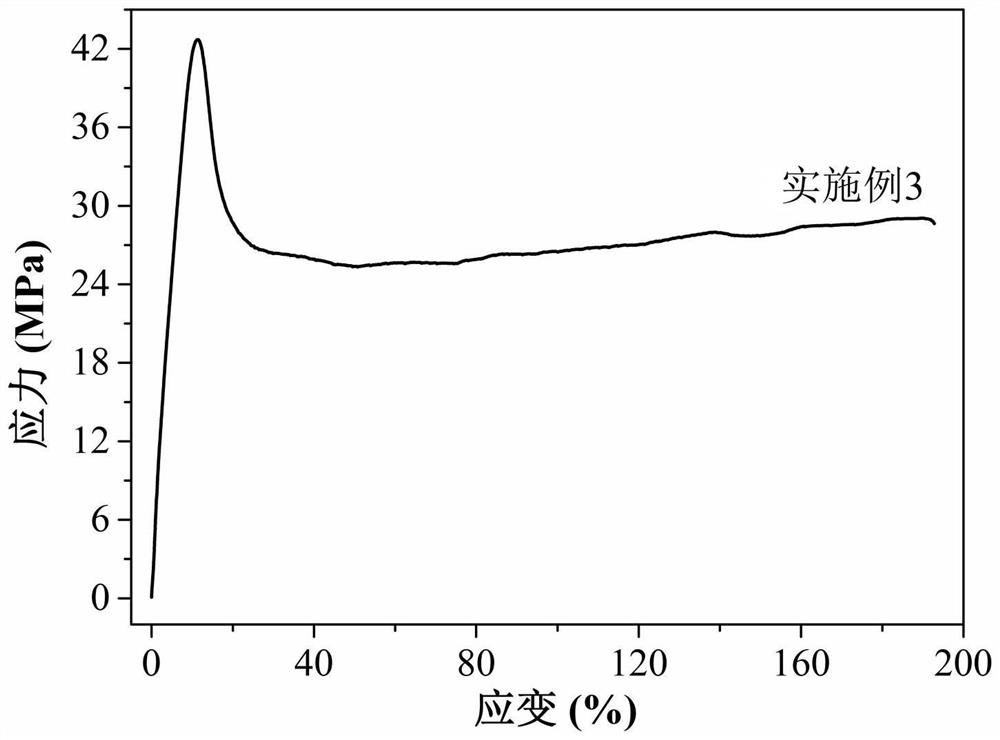

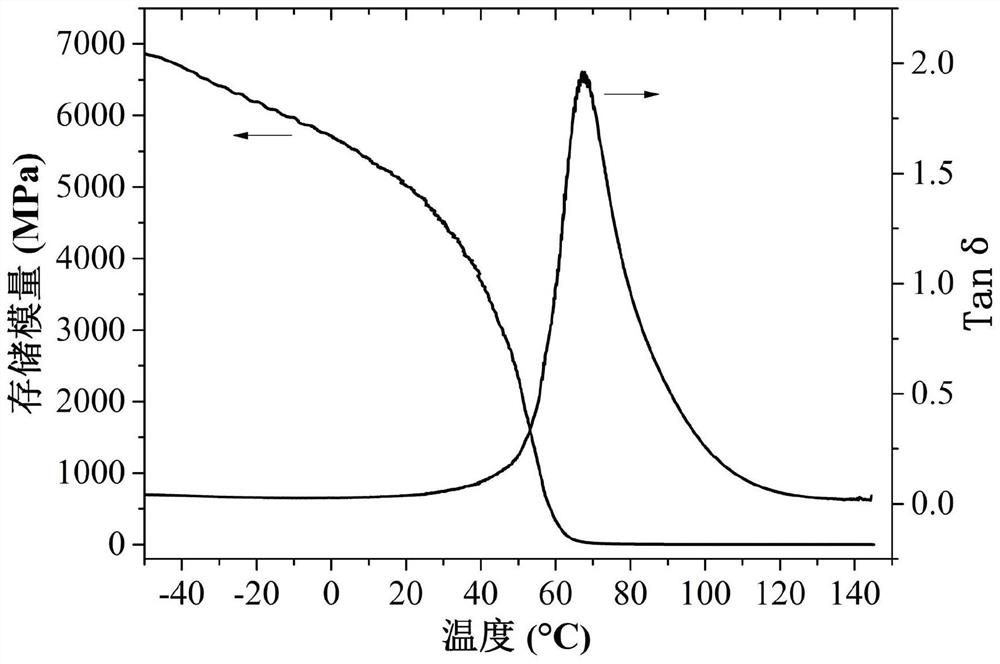

Embodiment 3

[0086] 1, with embodiment 1.

[0087] 2. After it is completely dissolved, add 1.2g methacrylic acid, 0.994g acrylamide, 2.94g N-isopropylacrylamide and 0.064g photoinitiator 2,2-dimethoxy-2-phenylphenethyl ketone. Nitrogen gas was bubbled for 20 minutes to remove dissolved oxygen, and the mixed solution was slowly injected into the glass mold with a disposable syringe, and multiple molds injected with the reaction mixed solution were placed under an ultraviolet device for photocrosslinking reaction, wherein the ultraviolet light intensity was 10mW / cm 2 . Illuminate for 20 minutes before and after the mold. After the reaction is over, take the cross-linked polymer material out of the mold and place it on a polytetrafluoroethylene film, dry it in an oven at 60°C for 12 hours, and then raise the temperature to 80°C under vacuum. Dry for 12 hours to obtain the shape-memory polymer material, which is a temperature-responsive or water-responsive shape-memory polymer material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com