A corrosion-resistant water-based metal rust inhibitor

A rust inhibitor and base metal technology, applied in the direction of metal material coating process, etc., can solve problems such as damage, shortening of rust prevention period, and unsatisfactory rust prevention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of modified corrosion inhibitor additive is:

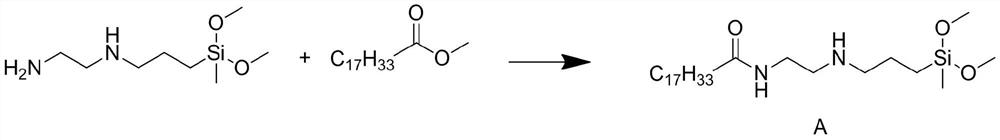

[0027] The first step, preparation of oleic acid imide ethyl aminopropyl silane

[0028] Add 1.1mol of methyl oleate into the reactor, replace the air in the reactor with nitrogen, heat to 95°C, then add 5g of catalyst sodium hydroxide, drop by drop 1mol of aminoethylaminopropyl dimethyl Oxysilane, keep the nitrogen flowing to get rid of the generated methanol, after the dropwise addition, continue to stir the reaction for 4h, after the reaction is over, distill under reduced pressure and vacuum dry to obtain oleic acid imide ethylaminopropylsilane A, The reaction formula is as follows:

[0029]

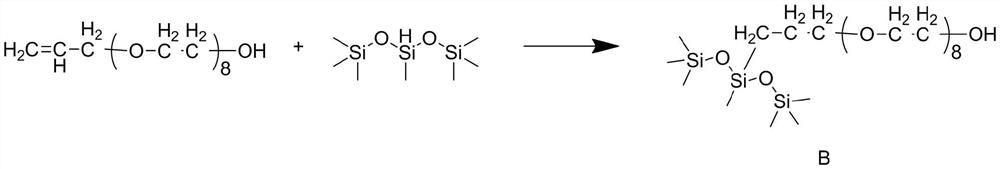

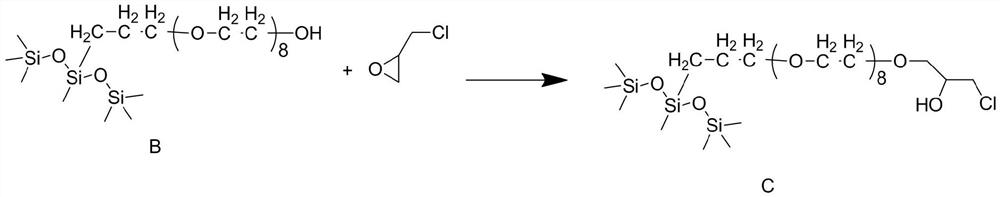

[0030] The second step, the preparation of modifier

[0031] S1. Add 1.1mol allyl polyoxyethylene ether, 3mmol metal platinum catalyst and 500ml toluene into the reactor, replace the air in the reactor with nitrogen, heat to 75°C, stir for 20min, add 1mol heptamethylsilane Oxygen, heat up to 105 ° C, k...

Embodiment 2

[0045] A corrosion-resistant water-based metal antirust agent, comprising the raw materials of the following parts by weight: 40 parts of corrosion inhibitor compositions, 2 parts of modified corrosion inhibition aids (prepared in Example 1), 1 part of rosin, 2 parts of boric acid, 1 part of antioxidant, 0.2 part of defoamer, 1 part of penetrant, 70 parts of distilled water;

[0046] The corrosion inhibitor composition is SiO 2 :Na 2 O: water = 52:16:32;

[0047] Described antioxidant is tert-butyl hydroquinone;

[0048] Described defoamer polyoxypropylene polyoxyethylene glyceryl ether;

[0049] Described penetration agent is oleic acid;

[0050] The preparation method of the rust inhibitor is as follows: first dissolve the corrosion inhibitor composition and the modified corrosion inhibitor additive in distilled water, then add rosin, antioxidant, defoamer and penetrating agent, and stir for 1 hour at a speed of 600rpm / min Finally, add boric acid at the end and stir slo...

Embodiment 3

[0055] A corrosion-resistant water-based metal antirust agent, comprising the raw materials of the following parts by weight: 50 parts of corrosion inhibitor compositions, 3 parts of modified corrosion inhibition aids (prepared in Example 1), 1 part of rosin, 4 parts of boric acid, 0.6 parts of antioxidant, 0.4 parts of defoamer, 2 parts of penetrant, 120 parts of distilled water;

[0056] The corrosion inhibitor composition is SiO 2 :Na 2 O: water = 50:20:34;

[0057] Described antioxidant is tert-butyl hydroquinone;

[0058] Described defoamer polyoxypropylene polyoxyethylene glyceryl ether;

[0059] Described penetration agent is oleic acid;

[0060] The preparation method of the rust inhibitor is as follows: first dissolve the corrosion inhibitor composition and the modified corrosion inhibitor additive in distilled water, then add rosin, antioxidant, defoamer and penetrating agent, and stir for 1 hour at a speed of 800rpm / min Finally, add boric acid at the end and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com