a nanoscale Fe 9 ni 9 the s 16 Preparation method of based electrocatalyst

A fe9ni9s16 and catalyst technology, which is applied in the field of preparation of nano-scale Fe9Ni9S16-based electrocatalysts, can solve the problems of unfavorable large particle size, complicated procedures, high energy consumption and the like, and achieves the effects of simple process, low cost and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

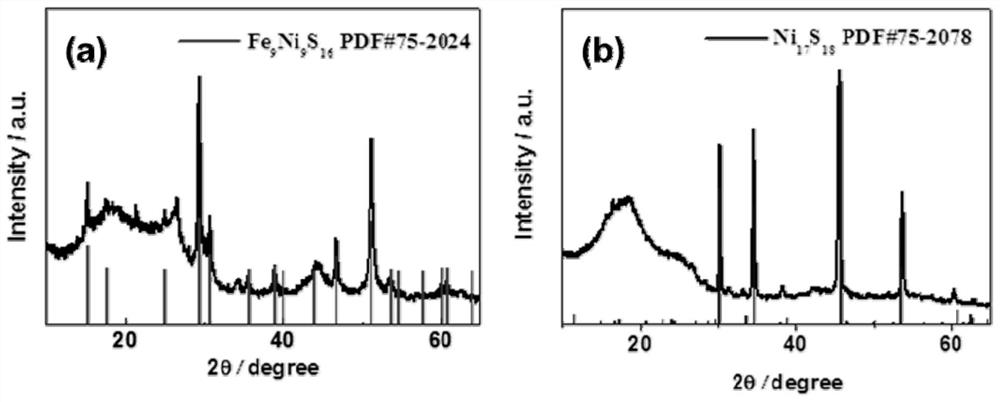

[0033] Weigh 13mgFeCl 3 ·6H 2 O, 12mgNiCl 2 ·6H 2 0. 50mg of thiourea is a precursor, dissolved in 10mL of deionized water, after adding 1mL of ethanol, then adding 25mg of carbon nanotubes, after continuing to stir for 12h, utilizing liquid nitrogen to freeze, and carry out freeze-drying, the sample after getting the freeze-drying is fully Grind, then put into a caulking boat, put in a 50 sccm Ar flow at 600° C. for 1 h, and use X-ray diffraction (XRD) to study the phase composition of the final sample.

[0034] X-ray testing equipment and conditions: RigakuD / max2500, CuKα rays. Such as figure 1 The XRD pattern of the sample shown, as can be seen from the figure, the diffraction pattern is consistent with the PDF card 75-2024, indicating that the phase structure of the sample is Fe 9 Ni 9 S 16 .

Embodiment 2

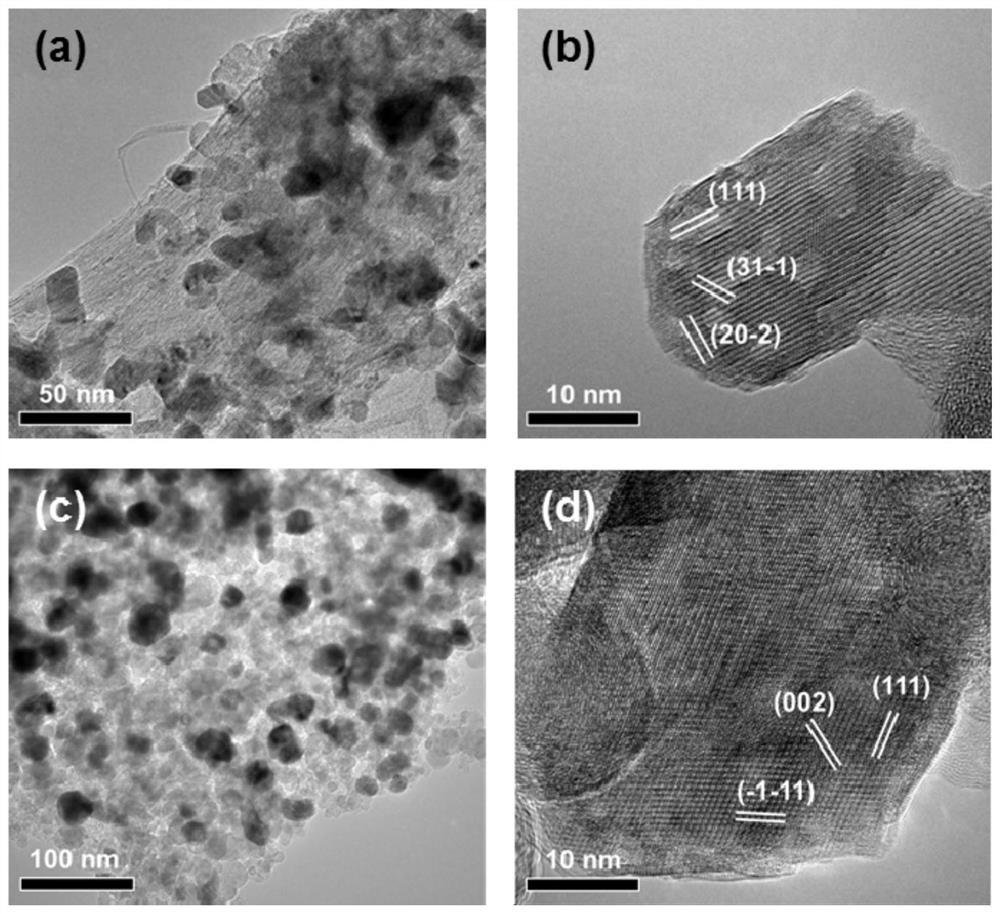

[0036] Weigh 13mgFeCl 3 ·6H 2 O, 12mgNiCl 2 ·6H 2 0. 50mg of thiourea is a precursor, dissolved in 10mL of deionized water, after adding 1mL of ethanol, then adding 25mg of carbon nanotubes or 25mg of commercial carbon black (XC-72R), after continuing to stir for 12h, utilizing liquid nitrogen to freeze, and Freeze-drying is carried out, and the freeze-dried sample is fully ground, then put into a burning boat, and placed in a 50 sccmAr airflow at 600 ° C for 1 h, and then its morphology and microstructure are characterized by TEM.

[0037] TEM characterization equipment: Tencai-F20, the voltage used is 200kV. Such as figure 2 (a, b) and (c, d) are the morphologies of samples obtained when using carbon nanotubes and using XC-72R as the carrier, respectively. It can be seen from the morphology of the two samples that, in addition to the difference between the carbon tubes and carbon spheres, the active material Fe 9 Ni 9 S 16 The morphology on the two supports is basic...

Embodiment 3

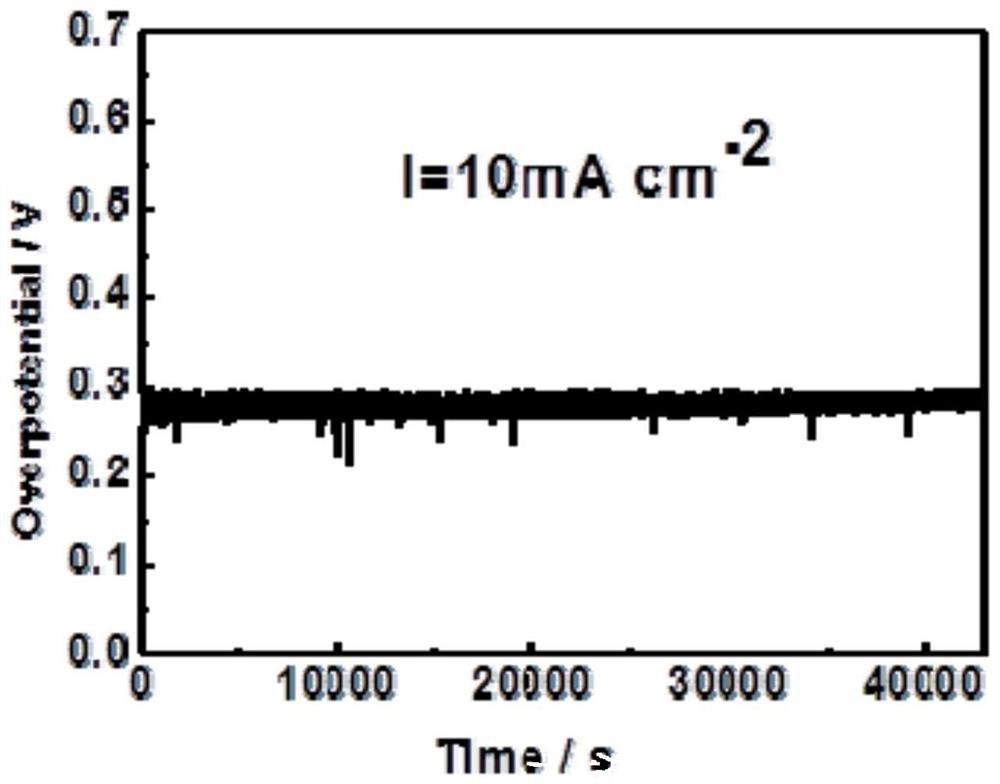

[0039] Weigh 13mgFeCl 3 ·6H 2 O, 12mgNiCl 2 ·6H 2 O. 50mg of thiourea as a precursor, dissolved in 10mL of deionized water, added 1mL of ethanol, then added 25mg of XC-72R, continued to stir for 12 hours, frozen with liquid nitrogen, and lyophilized, and the lyophilized sample was fully ground , and then placed in a burning boat, placed in a 50 sccm Ar flow at 600 ° C for 1 h, and then tested for its electrocatalytic oxygen production activity.

[0040] Electrocatalytic oxygen generation test conditions: 5 mg of sample is first dispersed in 1 mL of 25 vol% ethanol aqueous solution, and 30 μL of perfluorinated ionic polymer (Nafion) is dropped into it, and then 20 μL of it is dropped into a rotating disk electrode with a diameter of 5 mm in multiple times Above, after natural drying, put it on the rotating disk electrode device produced by Pine Company, the electrode rotation speed is 1600 rpm, use EC-LabVSP300 electrochemical workstation to test, the voltage scanning speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com