Anti-dropping macromolecular sulfonate flame retardant and preparation method therefor

A polymer sulfonate and flame retardant technology, applied in the polymer field, can solve the problems of large application limitations, easy precipitation, lack of physical entanglement, etc., to achieve low production cost, improved flame retardant performance, and efficient flame retardant. The effect of resistance and drip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

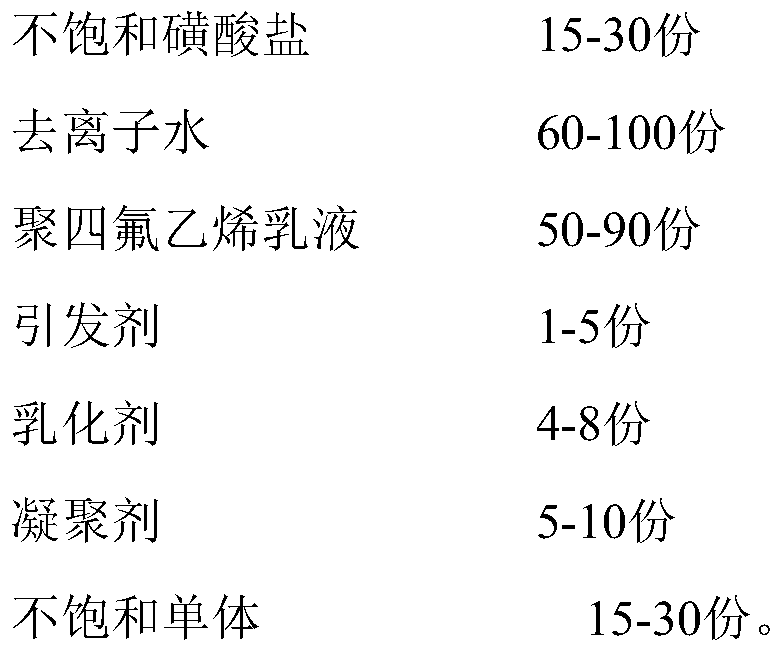

[0027] An anti-dripping polymer sulfonate flame retardant, comprising the following raw materials in parts by weight:

[0028]

[0029] Each part of the unsaturated sulfonate is a mixture of sodium styrene sulfonate, sodium vinyl sulfonate and sodium methallyl sulfonate in a weight ratio of 0.8:0.4:0.1.

[0030] Each part of the unsaturated monomer is a mixture of vinyl ethyl ether, styrene and acrylonitrile in a weight ratio of 0.8:0.1:0.4.

[0031] Each part of the initiator is a mixture of ammonium persulfate, potassium persulfate and tert-butyl hydroperoxide-sodium bisulfite redox system in a weight ratio of 0.5:0.8:0.4.

[0032] Each part of the coagulant is calcium chloride.

[0033] Each part of the emulsifier is a mixture composed of fatty acid sulfoalkyl ester, N-alkyldiethanolamine salt and alkylphenol polyoxyethylene ether in a weight ratio of 0.8:0.4:0.6.

[0034] The anti-dripping polymer sulfonate flame retardant comprises the following steps:

[0035] 1) M...

Embodiment 2

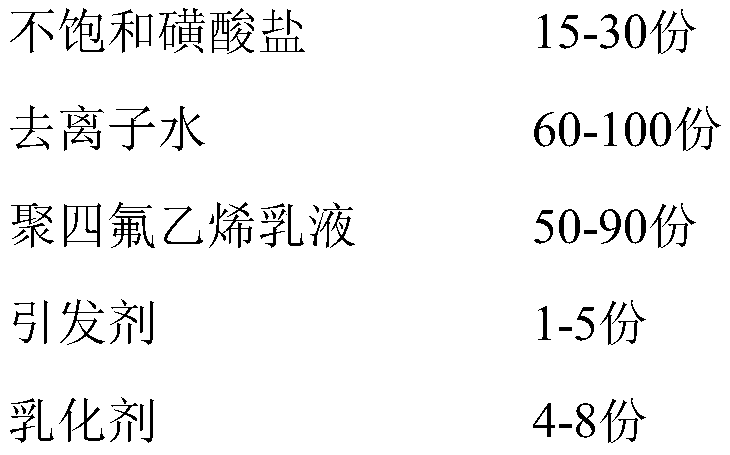

[0040] An anti-dripping polymer sulfonate flame retardant, comprising the following raw materials in parts by weight:

[0041]

[0042] Each part of the unsaturated sulfonate is a mixture of sodium styrene sulfonate, sodium vinyl sulfonate and sodium methallyl sulfonate in a weight ratio of 0.9:0.5:0.2.

[0043] Each part of the unsaturated monomer is a mixture of vinyl ethyl ether, styrene and acrylonitrile in a weight ratio of 0.9:0.2:0.5.

[0044] Each part of the initiator is a mixture of ammonium persulfate, potassium persulfate and tert-butyl hydroperoxide-sodium bisulfite redox system in a weight ratio of 0.6:0.9:0.5.

[0045] Each part of the coagulant is calcium chloride.

[0046] Each part of the emulsifier is a mixture composed of fatty acid sulfoalkyl ester, N-alkyldiethanolamine salt and alkylphenol polyoxyethylene ether in a weight ratio of 0.9:0.5:0.7.

[0047] The anti-dripping polymer sulfonate flame retardant comprises the following steps:

[0048] 1) M...

Embodiment 3

[0054] An anti-dripping polymer sulfonate flame retardant, comprising the following raw materials in parts by weight:

[0055]

[0056] Each part of the unsaturated sulfonate is a mixture of sodium styrene sulfonate, sodium vinyl sulfonate and sodium methallyl sulfonate in a weight ratio of 1.0:0.6:0.3.

[0057] Each part of the unsaturated monomer is a mixture of vinyl ethyl ether, styrene and acrylonitrile in a weight ratio of 1.0:0.3:0.6.

[0058] Each part of the initiator is a mixture of ammonium persulfate, potassium persulfate and tert-butyl hydroperoxide-sodium bisulfite redox system in a weight ratio of 0.7:1.0:0.6.

[0059] Each part of the coagulant is calcium chloride.

[0060] Each part of the emulsifier is a mixture composed of fatty acid sulfoalkyl ester, N-alkyldiethanolamine salt and alkylphenol polyoxyethylene ether in a weight ratio of 1.0:0.6:0.8.

[0061] The anti-dripping polymer sulfonate flame retardant comprises the following steps:

[0062] 1) M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com