A kind of hydrothermal carbon-based composite material, its preparation and application

A technology of composite materials and hydrothermal carbon, which is applied in the direction of water pollutants, other chemical processes, water/sewage treatment, etc., can solve the problems of poor adsorption effect and difficult availability of heavy metal raw materials, etc., and achieve improved pore size controllability, ratio The effect of increasing the surface area and improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a hydrothermal carbon-based composite material provided by the invention comprises the following steps:

[0027] (1) Mixing the biomass with the metal-organic framework material precursor solution to obtain a raw material mixture;

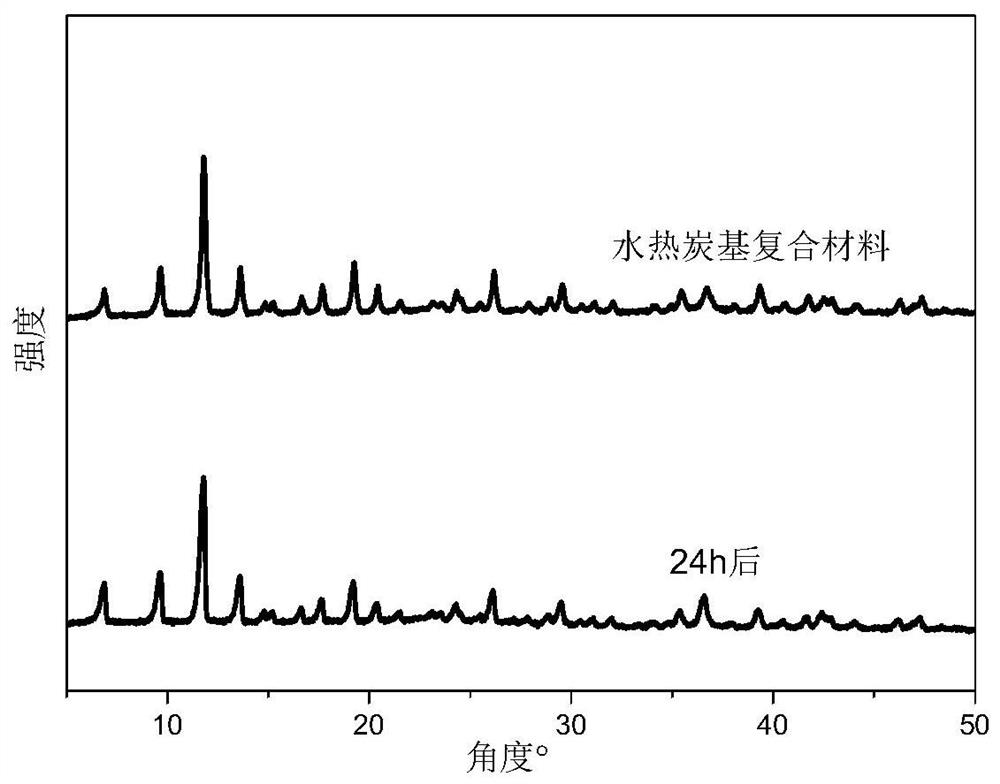

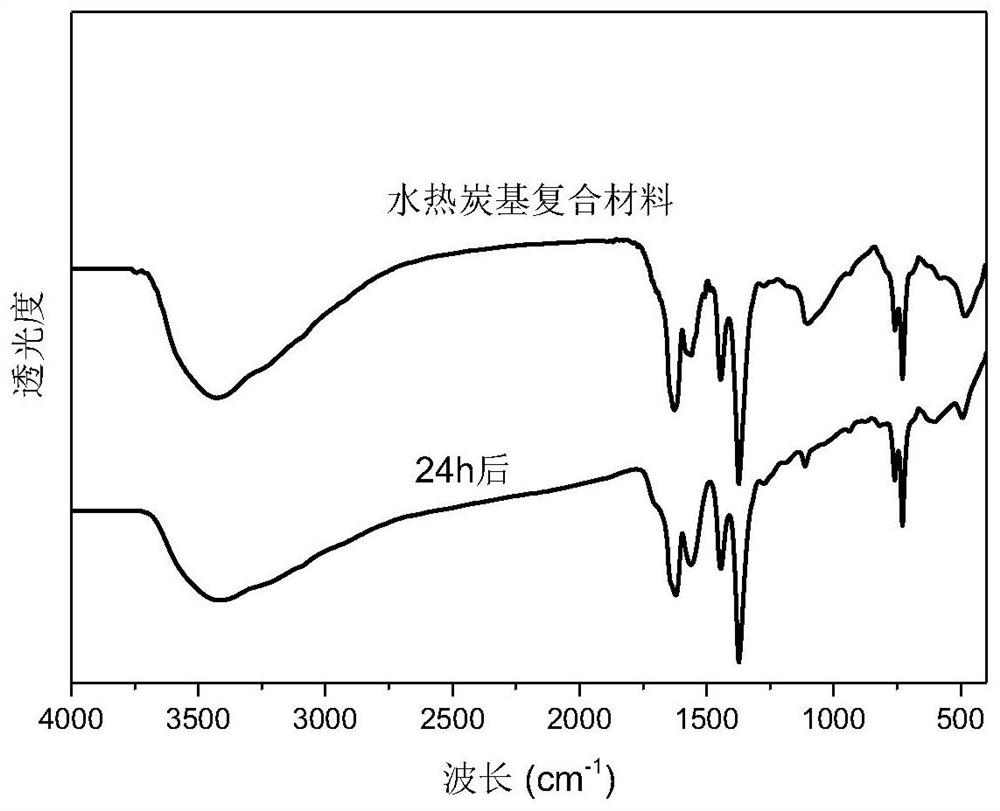

[0028] (2) The raw material mixture is subjected to a hydrothermal reaction in a closed reactor, during which the carbonization of the biomass and the crystallization reaction of the metal-organic framework material take place; after the hydrothermal reaction is completed, the solid-liquid separation is After the obtained solid material is cleaned and dried, the hydrothermal carbon-based composite material is obtained.

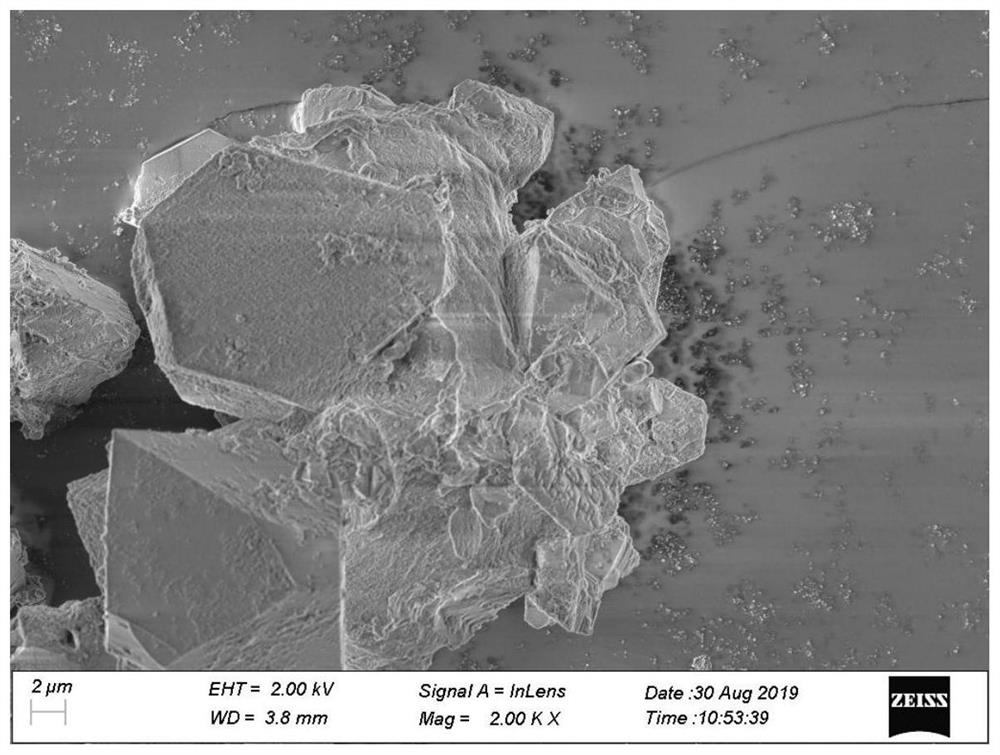

[0029] The particle size of the biomass raw material affects the physical properties of the formed hydrothermal carbon, thereby affecting its recombination with the metal-organic framework. Controlling the particle size within the above range can effectively make the growth process of the metal-organic...

Embodiment 1

[0054] The specific surface area and pore structure of the hydrothermal carbon and the hydrothermal carbon-based composite material in Example 1 are as follows:

[0055] Table 1

[0056]

[0057] The adsorption efficiency of hydrothermal carbon and hydrothermal carbon-based composite materials to various heavy metals in the liquid phase in Example 1 is as follows:

[0058] Table 2

[0059]

Embodiment 2

[0061] A method for preparing a hydrothermal carbon-based composite material, comprising the steps of:

[0062] (1) Grinding the stalks into fine particles after air-drying;

[0063] (2) Dissolve aluminum nitrate nonahydrate and trimesic acid in a certain proportion in the reaction solvent respectively, mix them well, the solvent is deionized water, the mass ratio of aluminum nitrate nonahydrate and trimesic acid to solvent is 5:1 :8;

[0064] (3) Add the straw granules in step 1 to the mixed solution prepared in step 2, and mix thoroughly; the mass ratio of the straw to the mixed solution is 1:1;

[0065] (4) Put the mixed solution prepared in step 3 into a closed reaction kettle with a stirrer for carbonization and crystallization reaction, the heating rate is 5°C / min, the reaction temperature is 250°C, the reaction time is 48h, and the stirring rate 300rpm.

[0066] (5) After cooling, the solid obtained in step 4 was collected by centrifugation, and washed 3 times with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com