A preparation method of mechanofluorescent color-tunable carbon dots

A fluorescence and color technology, used in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve problems such as cumbersome steps, and achieve the effects of simple operation, expansion of development and application fields, and short reaction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

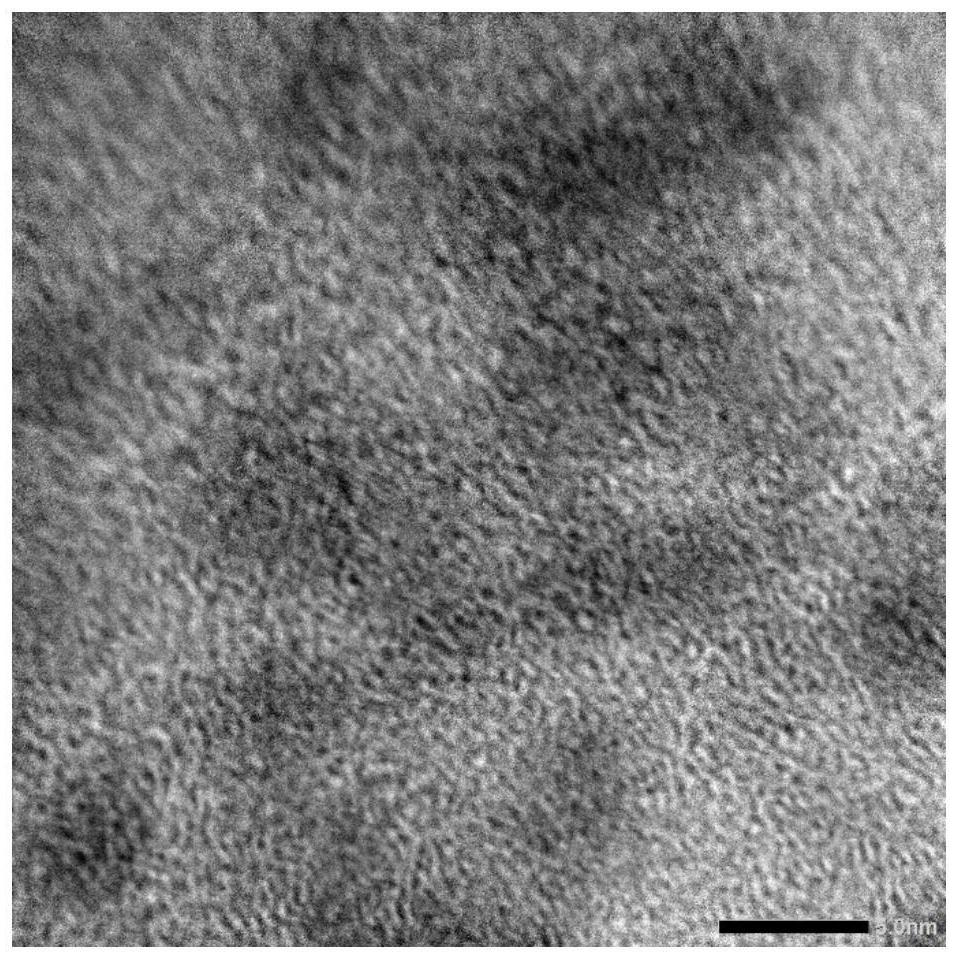

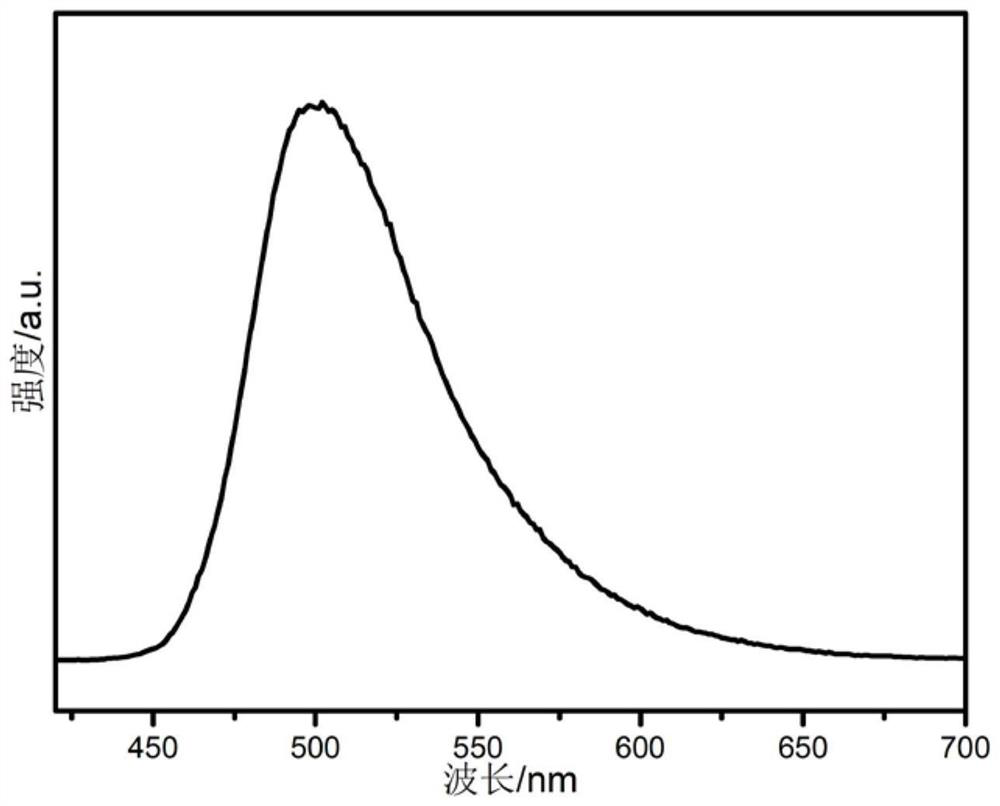

Embodiment 1

[0037] 1. Measure 5 mL each of N, N-dimethylformamide and distilled water into a polytetrafluoroethylene reactor, and weigh 34 mg (0.05 mmol) of 1,3,6,8-tetrakis(4-carboxybenzene) Pyrene and 20 μL (0.3 mmol) of analytically pure ethylenediamine were added to the mixed solution, and sonicated until the solid was dissolved. After reacting for 6 h in an air-blast drying oven at 180° C., it was naturally cooled to room temperature. Transfer the product in the polytetrafluoroethylene reactor to a 500D dialysis bag, dialyze with distilled water for 24 hours, and change the distilled water every 4 hours; then put the liquid in the dialysis bag into a centrifuge tube and centrifuge at a speed of 11000r / min for 15 minutes; Take the supernatant and dry the liquid in a blast drying oven to finally obtain a yellow-green solid powder, which appears yellow-green under a 365nm ultraviolet lamp. figure 2 It is the fluorescence emission spectrum of the carbon dots without grinding treatment ...

Embodiment 2

[0041]Step 1 is the same as Step 1 of Example 1. In Step 2, it is only necessary to change the grinding time of 1 min in Step 2 of Example 1 to 5 min, and other conditions remain unchanged. Finally, the fluorescence emission spectrum at the excitation wavelength of 365nm was obtained. Figure 4 It is the fluorescence emission spectrum of the carbon dots ground for 5 minutes at the excitation wavelength of 365nm, and the emission peak is observed at 497nm.

Embodiment 3

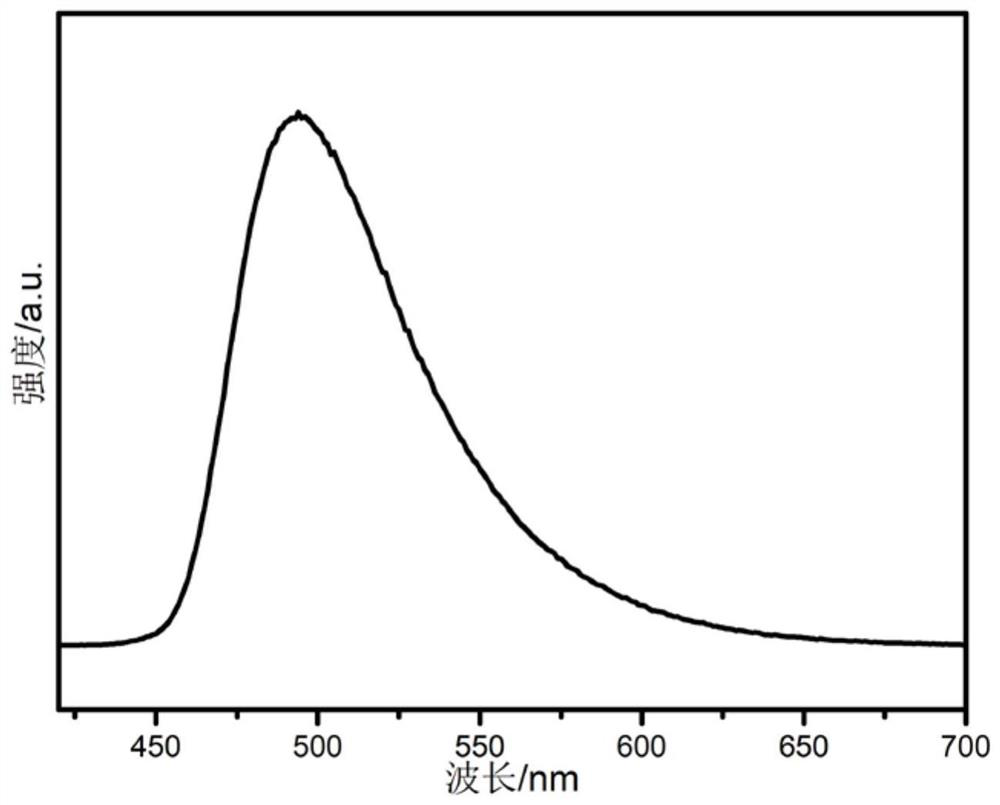

[0043] Step 1 is the same as Step 1 of Example 1. In Step 2, it is only necessary to change the grinding time of 1 min in Step 2 of Example 1 to 10 min, and other conditions remain unchanged. Finally, the fluorescence emission spectrum at the excitation wavelength of 365nm was obtained. Figure 5 It is the fluorescence emission spectrum of the carbon dots ground for 10 min at the excitation wavelength of 365nm, and the emission peak is observed at 495nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com